Studio facilities are used to make films and are usually handled by the production company. Most firms in the entertainment industry have never owned their own studios, but have rented space from other companies.

Film studios are usually housed inside a “studio lot”, a secure compound enclosed by a tall perimeter wall to protect filmmaking operations from unwanted interference.

Studio facilities typically consist of at least one sound stage, office space for studio executives and production companies, makeup and rehearsal rooms and a studio commissary (the term used in the industry for a company cafeteria).

The largest film studios offer the entire range of production and post-production services required to make a motion picture. This includes, costumes, props, cameras, sound recording, sets, lighting, special effects, cutting, editing, mixing, scoring, ADR, re-recording and foley.

Studio facilities can have thousands of personnel on site at any given time. They can also contain mountains of incredibly expensive equipment. Therefore, it is essential that they have suitable fire detection equipment installed to protect people and property from fire. Furthermore, the resulting downtime caused by fire damage could create huge delays in production and cost millions.

Aspirating Smoke Detection

Aspirating smoke detection provides extremely fast and reliable detection of smoke. It is suited to most environments including large open spaces, areas with high or varying airflow, dusty or dirty environments and more.

Aspirating smoke detection works by drawing samples of air from the protected area into a detection chamber. The sampled air is then analysed and, if smoke particles are found, a signal is sent to the fire alarm control panel to act accordingly.

Sampling points are small and discrete so do not interfere with the aesthetics of the area (which is particularly important for sound stages). The detectors themselves can be installed out of the wayt in a separate area where they can be easily accessed for maintenance purposes.

The air is filtered before it enters the detection chamber to remove contaminants and sophisticated algorithms are able to differentiate between dust and smoke – this reduces false alarms and unnecessary evacuation which ultimately prevents delays in production.

Eurofyre has represented Xtralis as a major technical wholesaler since 2007. This means we can supply and offer specialist technical support for their entire range of aspirating smoke detection including: VESDA; VESDA-E, ICAM and FAAST.

Handpicked Products for Studio Facilities

The VESDA-E VEP series of aspirating smoke detectors use advanced Flair Detection Technology, a revolutionary detection chamber that contains a CMOS imager, and multipole photodiodes to provide accurate and direct imaging of the data and ensure a very early warning of fire while minimising nuisance alarms.

They offer absolute calibration, multi-stage filtration and optical protection with clean air barriers to deliver continuous, reliable performance and a smart, on-board filter retains a dust count and remaining filter life to make scheduled maintenance easy.

VESDA-E VEP detectors have a wide sensitivity range, use flow fault thresholds for each port to support changeable airflow conditions and have four alarm levels making them suitable for a huge variety of applications including all the facilities inside a studio lot.

VESDA-E Aspirating Smoke Detectors

VESDA-E VEP 4 pipe aspirating smoke detectors provide coverage for open areas of up to 2,000m2. They too provide a very early warning of fire while minimising nuisance alarms and offer absolute calibration, multi-stage filtration and optical protection with clean air barriers to provide continual detection performance.

VESDA-E Power Supplies and Filters

VESDA-E STX power supplies are designed to complement the style and look of all the detectors in the VESDA-E range. They are technically matched to provide sufficient current and battery charging capacity to meet EN54-4 requirements and are VdS approved.

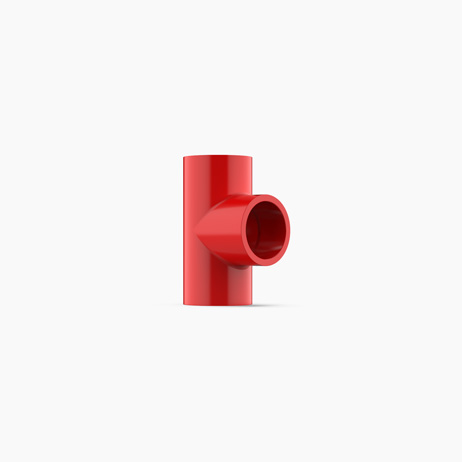

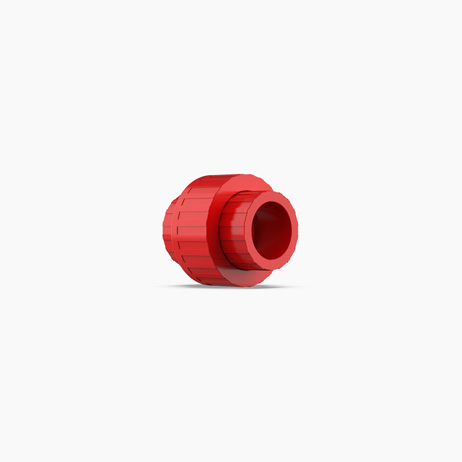

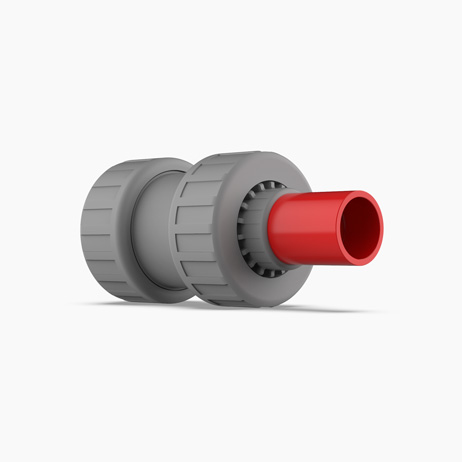

25mm Pipe & Fittings

Flexible connectors are installed where a bend or elbow are not suitable. The flexible connector is strengthened internally with a steel wire and can be mounted in any direction without reducing the flow of air.

Air sampling test points allow for functional smoke testing of aspirating smoke detection systems and are typically located at the end of a sampling pipe network.

This pipe clip has been designed to secure air-sampling pipe using a quick clamp action without the need for additional fixings. Additional fixing nuts and side rod connectors complement the pipe clip for greater installation flexibility.

When installed close to the aspirating smoke detector, the quick release airline can be used to shut the air off to the detector while the compressed air delivery system can be easily and quickly connected to the quick-release connectors. This allows the air to be effectively blown through the system without damaging the detector.

Why Choose Eurofyre?

- Complete System Supplier

- Eurofyre is a complete system supplier and has been a major Xtralis technical wholesaler since 2007. This means we can offer expert advice and supply all aspects of fire detection including aspirating smoke detection systems, conventional and addressable fire alarm control panels and linear heat detection.

- Pipework Design

- Eurofyre can also provide assistance with aspirating pipe network design to ensure optimum network performance and installation quality.

- Demonstration and Training

- We have a sophisticated training facility where we offer demonstrations and expert training on a range of systems, including VESDA-E aspirating smoke detection systems.

- After-Sales Support

- Eurofyre prides itself on providing after-sales care and support that is second to none. We offer both on-site and telephone assistance to help you ensure that your system is fully operational and working at its best.

For more information about VESDA aspirating smoke detection, or to discuss any of the other products that Eurofyre have to offer, please feel free to get in touch either by phone on +44 (0) 1329 835 024, by email to [email protected] or via the online enquiry form situated on our contact page.

Don’t forget you can follow us on LinkedIn, Twitter and Facebook or sign up to our newsletter (in the footer below) to receive all the latest information from Eurofyre.