Refrigerated storage areas, sometimes known as a cool or cold store, are larger refrigerated rooms or buildings that are designed to store items that need to be kept below room temperature.

These areas are commonly used to store items like seafood, meat, fruit and vegetables and are usually found near shipping ports that are used for the import and export of produce.

Refrigerated storage areas come in a variety of different shapes and sizes. While some are considered very small, others have the capacity to store thousands of tonnes of produce.

These areas have a certain degree of fire risks and hazards and require suitable fire and gas detection to avoid potential fires and protect stock and staff from harm.

What are the Risks?

- Electrical Faults

- Electrical faults from electrical or mechanical equipment can cause sparks and ignite nearby flammable materials.

- Maintenance

- Maintenance operations and repairs can also cause flammable materials to catch alight.

- Fuel Hazards

- Highly combustible polystyrene, polyurethane foam, wooden pallets and plastic packaging can cause a fire to spread very quickly. The low humidity levels of cold stores can also cause a fire to burn stronger and quicker.

- Gas Presence

- Gases used in cooling processes can be flammable. If gas is to come into contact with an ignition source the results could be catastrophic.

- Dry Air

- Due to the low temperatures of a cold store, moisture can be absorbed from the air and make it hard for certain fire detection systems to detect when fire has broken out.

What are the Challenges?

- Storage Racking

- Storage racking can affect the airflow and impede the detection and response to a fire event.

- Low Temperatures

- Most detection types are not designed to operate in very low temperatures and would, therefore, be ineffective.

- High Airflows

- High airflows created by blast chiller units can also hamper the operation of conventional detectors.

- Ice Build-up

- In cold stores, it’s common for ice to build up on the surface. Therefore, the fire detection solution must be able to withstand potential build-up of ice on detectors.

- Condensation

- Condensation can also collect on items, including detectors, in cold store areas.

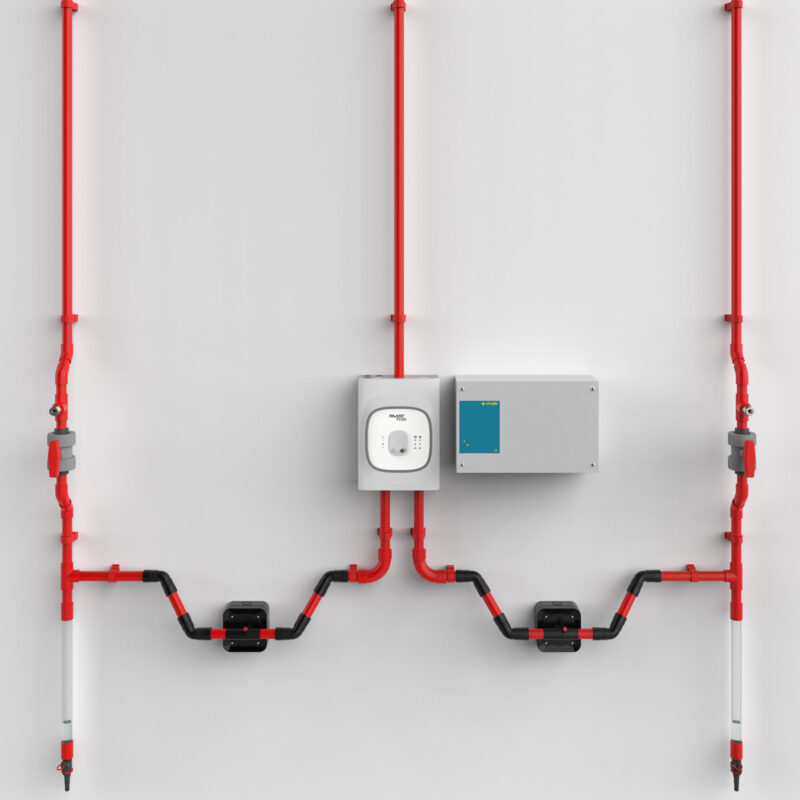

Combining FAAST FLEX with VESDA Sensepoint XCL

Aspirating smoke detection (ASD) provides the ideal solution for protecting refrigerated storage areas from fire. ASD uses powerful aspirators to draw samples of air from the protected area, this means that the detection unit does not need to be stored within the cold environment. It also means that smoke detection is unaffected by obstacles, varying airflows and low temperatures. ASD can also handle ice build-up and a water trap can be installed to deal with condensation.

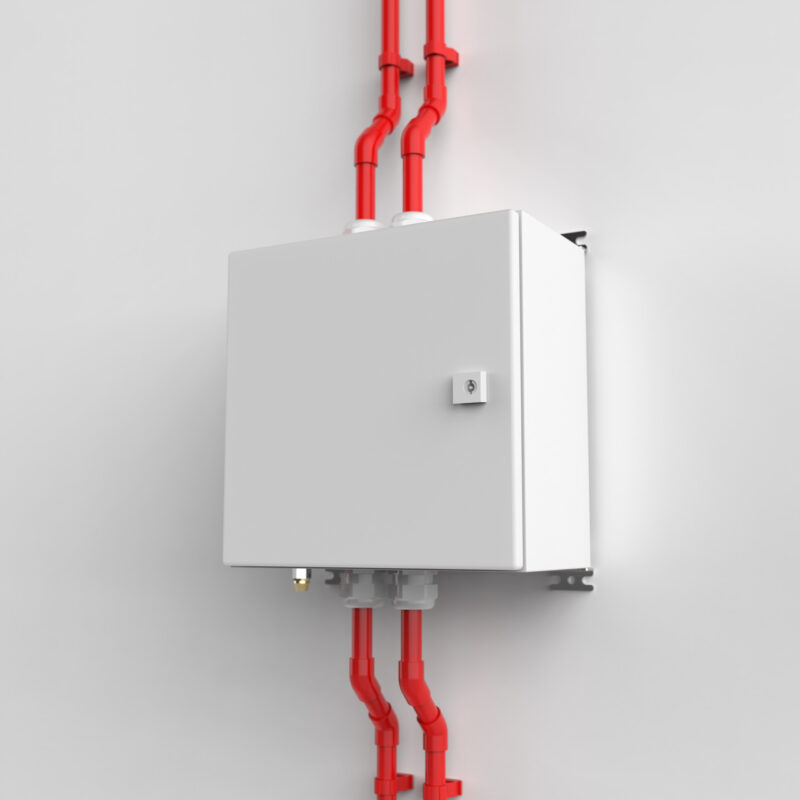

By combining ASD with in-line gas detection, leaking refrigerants can also be detected.

FAAST FLEX

FAAST FLEX is an advanced aspirating smoke detection system from Xtralis. It is designed specifically to provide Class A, B or C detection for areas up to 2,000m2 where configurability, sensitivity and very early warning of fire are required.

FAAST FLEX delivers flexible and cost-effective smoke detection for a variety of different applications including cold storage facilities. FAAST Flex continually draws air from the protected area through a network of sampling pipes. Once the air reaches the detection chamber, it is analysed to determine if any smoke is present. Pipe network designs can be pre-engineered to make installation and commissioning simple and the system can be configured without the need for specialist tools.

A Bluetooth interface allows FAAST FEX to be paired with a smartphone application that offers extended configuration options and rapid diagnostics.

VESDA Sensepoint XCL

Sensepoint XCL In-Line Gas Detectors provide aspirated gas detection for use with aspirating smoke detection systems like FAAST FLEX. These inline gas detectors provide a fast and reliable warning of harmful gases, such as refrigerant (NH3, CO2) which are common in cold stores, that are present in the detection area.

Sensepoint in-line gas detectors are easy-to-install, commission and operate via an embedded Bluetooth interface that can be paired with any smart device.

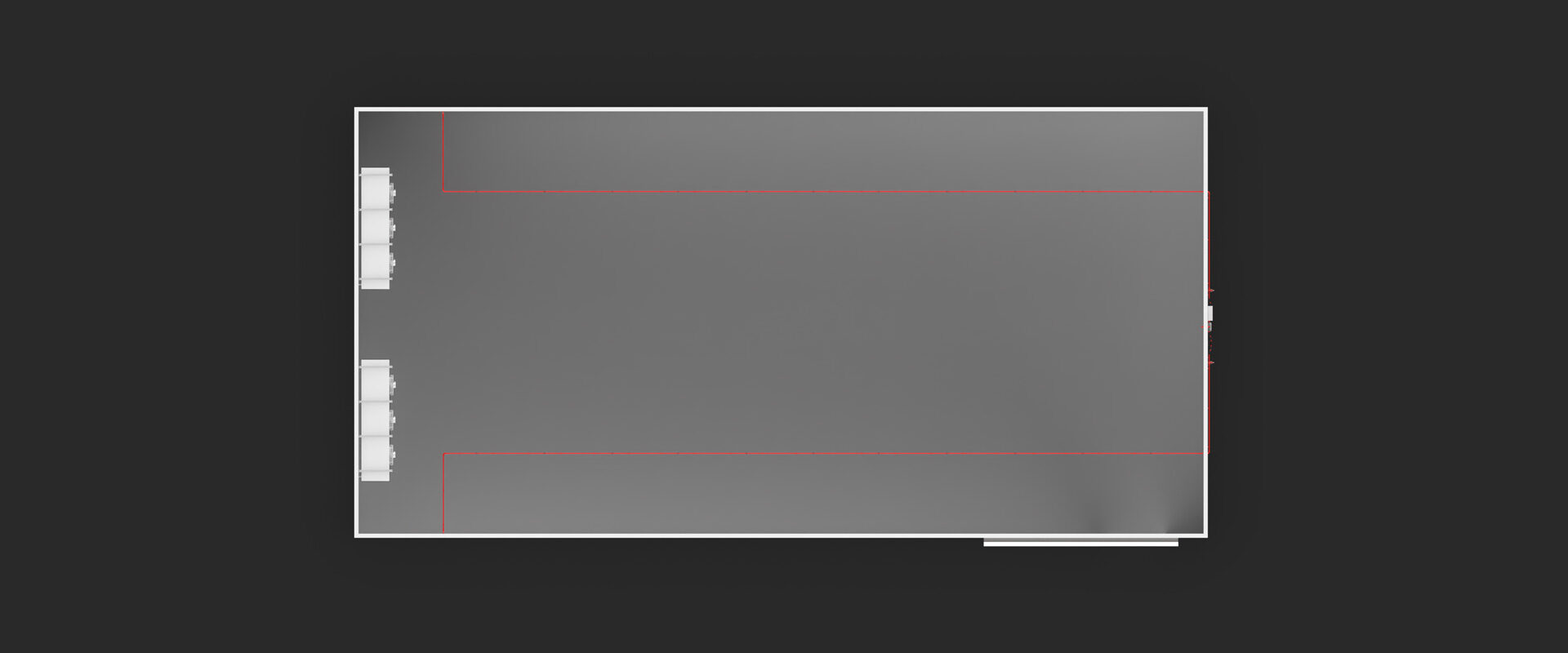

FAAST FLEX Design Considerations

There are a number of factors to consider when designing a FAAST FLEX system for refrigerated storage areas. These include things such as: the level of protection that is required; the temperature range the pipes will be subjected to; if any changes to the function of the area are expected; what the airflow characteristics of the protected areas are; and what effects defrost cycles may have on the detection system.

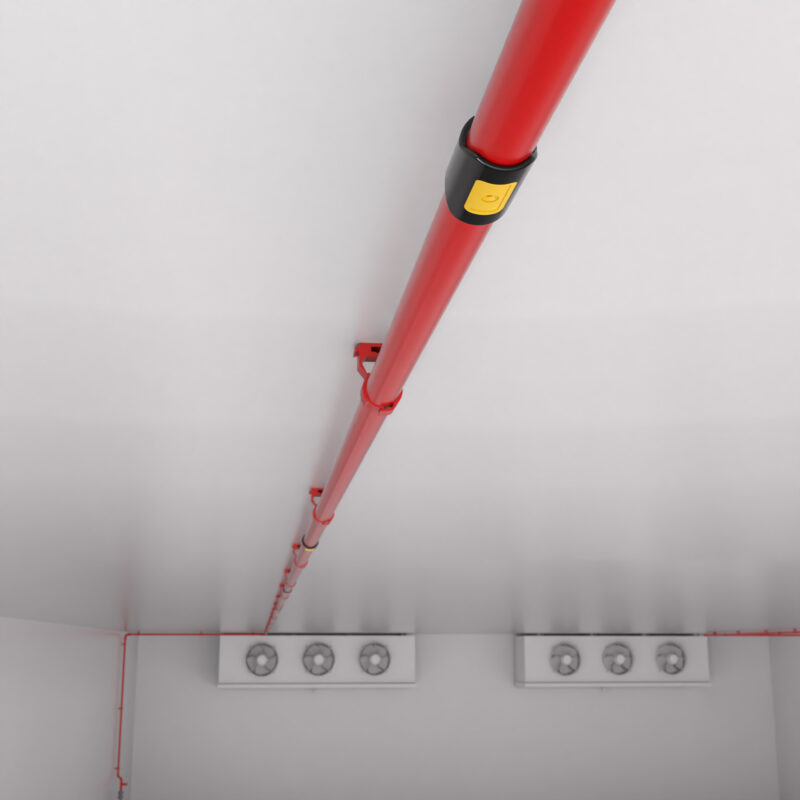

Positioning of Sampling Pipes and Sampling Holes

Sampling holes should be placed as far away from entrances as legally permitted and as far away from the chillers jets streams as possible. This will reduce the risk of ice build-up blocking the air’s path into the sampling pipe.

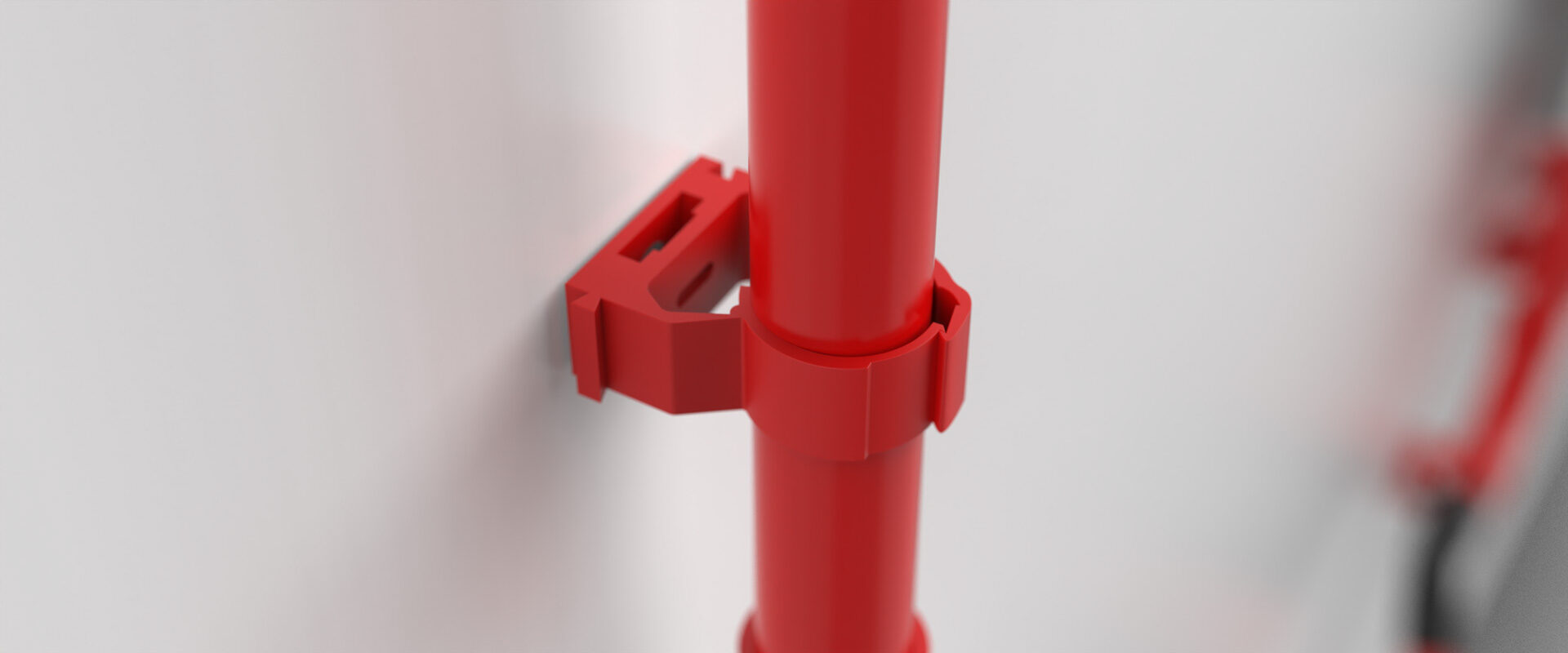

Sampling Pipe Contraction

Temperature variations will cause sampling pipes to contract and expand. Therefore, allowance for this must be taken into account. Mounting clips must not restrict longitudinal movement of the pipes as they expand or contract.

How to Prevent Ice Build-up

Ice may occasionally form on the exterior of sampling pipes. This build-up does not affect the operation of the FAAST FLEX system as long as it does not block the sampling holes. If ice does build up around the holes, it is recommended to use a blow-back method with compressed air.

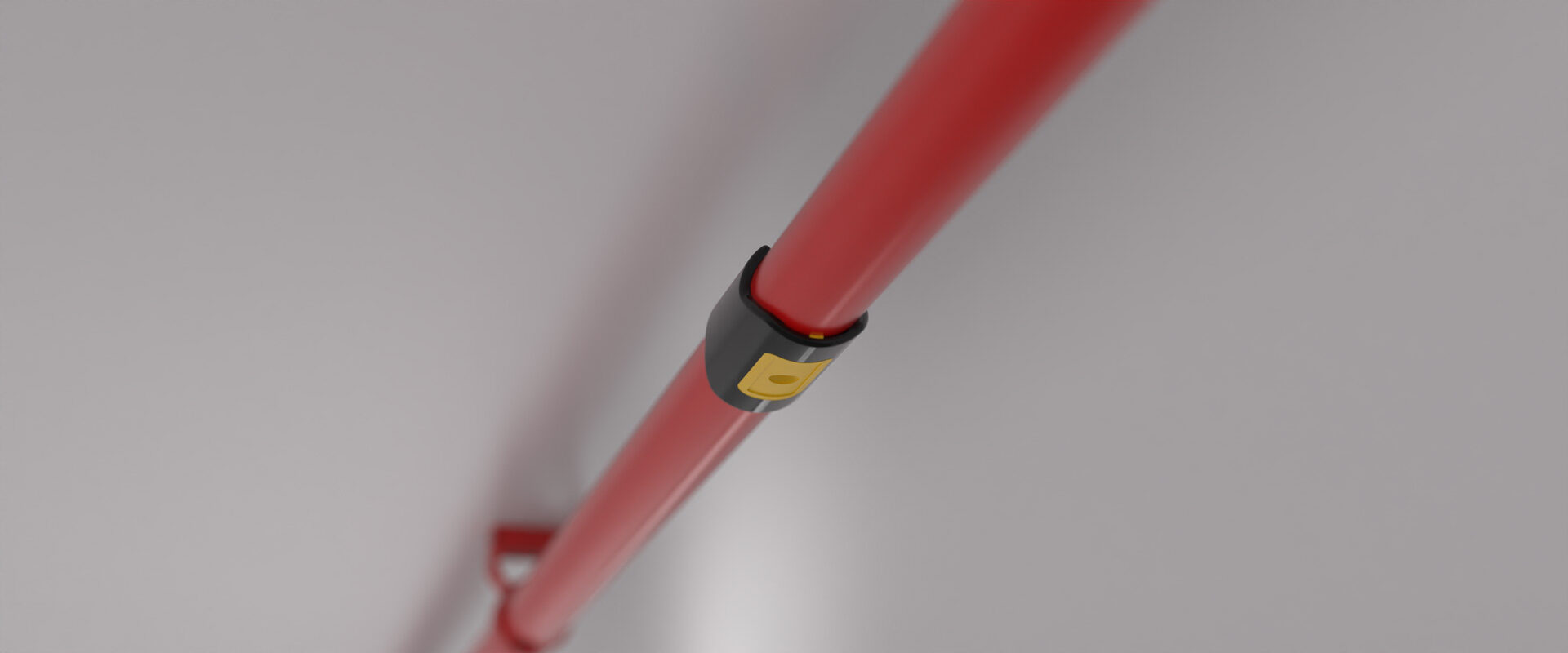

VESDA Harsh Environment Sampling Hole Clips provide reliable and accurate sampling hole sizes that are fast to install and easy to locate and identify. Each clip is colour-coded to indicate a specific hole diameter providing an instant visual guide and removing the need for closer inspection.

These clips are suitable for temperatures down to -40°C (-40°F) and are designed to flex to remove ice build-up when subjected to compressed air.

Water Trap

A water trap should be used to capture water condensate inside the sampling pipe and prevent it from entering the detector. The water trap consists of a transparent pipe connected to a tee section before the inverted detector. The transparent pipe provides a visual indication of the level of water and has a stop valve (or end cap) at the end to drain the water.

Blow-back Air Maintenance

Blow-back (compressed) air is used to remove ice build-up at sampling holes. A blow-back system, such as the Blazer, uses a compressed air supply connected to the pipe network that forces the ice out of the sampling holes.

The Blazer is an automatic aspiration maintenance system that is highly effective in blowing a network of pipes clean. It is installed right above the detector in the piping network and briefly blows pressurised air into the pipe in order to remove any accumulated ice. The pulsating effect of the air that is pushed through ensures that even persistent icing is stripped from the inside of the piping network and removed.

Why Choose Eurofyre?

- Xtralis Gold Partner

- Eurofyre has ‘Gold Channel Partner’ status with Xtralis – the market leader in aspirating smoke detection. This recognition displays our level of commitment, including excellent customer service and competitive pricing.

- Complete System Supplier

- Eurofyre is a complete system supplier and has been a major Xtralis technical wholesaler since 2007. This means we can offer expert advice and supply all aspects of fire detection including aspirating smoke detection systems, conventional and addressable fire alarm control panels and linear heat detection.

- Pipework Design

- Eurofyre can also provide assistance with aspirating pipe network design to ensure optimum network performance and installation quality.

- Demonstration and Training

- We have a sophisticated training facility where we offer demonstrations and expert training on a range of systems, including FAAST FLEX aspirating smoke detection systems.

- After-Sales Support

- Eurofyre prides itself on providing after-sales care and support that is second to none. We offer both on-site and telephone assistance to help you ensure that your system is fully operational and working at its best.

For more information about VESDA aspirating smoke detection, or to discuss any of the other products that Eurofyre have to offer, please feel free to get in touch either by phone on +44 (0) 1329 835 024, by email to [email protected] or via the online enquiry form situated on our contact page.

Don’t forget you can follow us on LinkedIn, Twitter and Facebook or sign up to our newsletter (in the footer below) to receive all the latest information from Eurofyre.