Conveyor belts are used for a variety of applications. Their primary function is to transport items from one place to another, saving both time and labour. Conveyors are durable and reliable components used in automated distribution and warehousing, as well as manufacturing and production facilities. They can be used for anything from moving boxes along a factory floor to transporting large volumes of resources and agricultural products such as grain, salt, coal, ore, sand, overburden and more.

In its simplest form, a conveyor belt system consists of at least two pulleys and a closed loop of medium (the belt). One or more of the pulleys are powered which rotates the belt around the pulleys, thus moving anything that is on top of the belt forward.

Risks and Challenges

There are a variety of fire risks that come with conveyor belt systems. These can include:

- Friction

- Excess heat caused by friction can cause dust or debris around the conveyor to catch fire.

- Electrical or Mechanical Faults

- Like with most electrical or mechanical equipment, faults can result in overheating or fire, this is especially likely to happen if the conveyor belt system is in an ill state of repair or mistreated.

- Hot or Burning Materials

- Conveyors are sometimes used to transport hot or burning materials. This means that, if the correct precautions are not taken, the materials being transported can cause a fire.

- Smouldering Materials

- Some materials, such as coal, can self ignite and smoulder for some time before flames become visible. The dust from this type of material is also extremely combustible. The threat from this type of material can go unnoticed.

There are also a variety of challenges that are presented when it comes to protecting conveyor belt systems from fire. If the fire is on the belt itself, it will likely be moving. This means that traditional type detectors will find it difficult to detect any smoke. Dust, dirt and other contaminants can also render traditional type detectors ineffective.

FyreLine EN54 Fixed Linear Heat Detection

Linear Heat Detection (LHD) can provide the ideal solution for protecting conveyor belt systems from fire. LHD uses heat sensing cables to detect rises in temperature. It is unaffected by airflow or contaminants and can provide fast and reliable detection in almost any environment. When the heat sensing cable reaches its rated temperature, the LHD controller sends a signal to the fire alarm control panel and shows the exact location of the event on its LCD panel.

EN54 is a suite of standards applicable to the components of a permanent fire alarm system. It is a mandatory standard that specifies the requirements for detection components and alarm systems and allows the free movement of construction products between countries within the European Union.

This means that if the conveyor belt system is in a facility that is governed by the European Commission, the fire alarm system used must be EN54 approved and bear the CE mark.

FyreLine EN54 Fixed Linear Heat Detection is fully approved by EN54 and carries the CE mark to show that it fulfils the European Union safety and performance requirements.

Approvals

The EN54 standard is a mandatory code that specifies requirements for detection components and alarm systems and allows the free movement of construction products between countries of the European Union. According to the Construction Products Regulation, it is mandatory that fire detection and fire alarm equipment is certified under the EN54 standard by an authorised certification body.

Please note: to comply with EN54-28, the FyreLine EN54 Fixed Controller, FyreLine EN54 Fixed EOL and FyreLine EN54 Fixed LSZH LHD Cable must be used as a complete system.

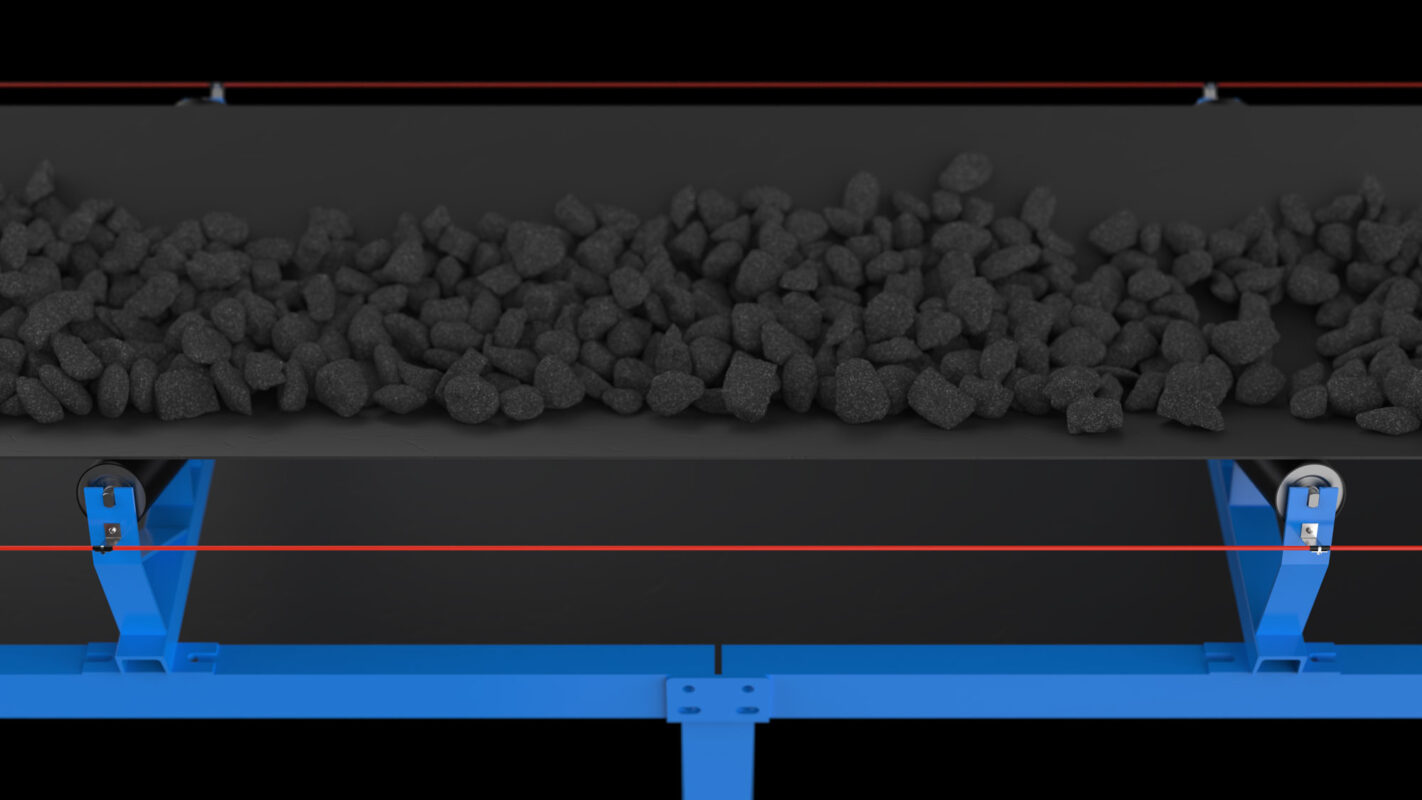

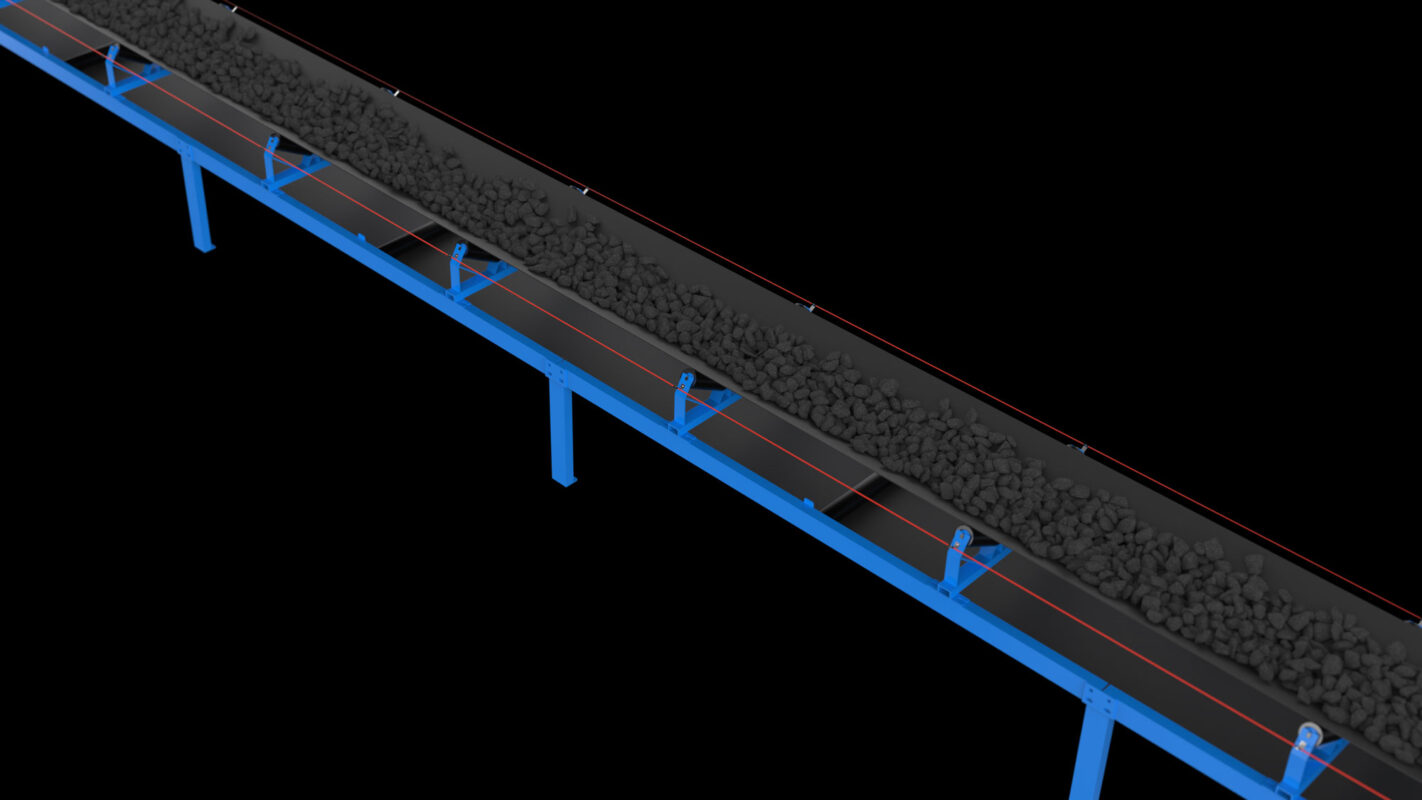

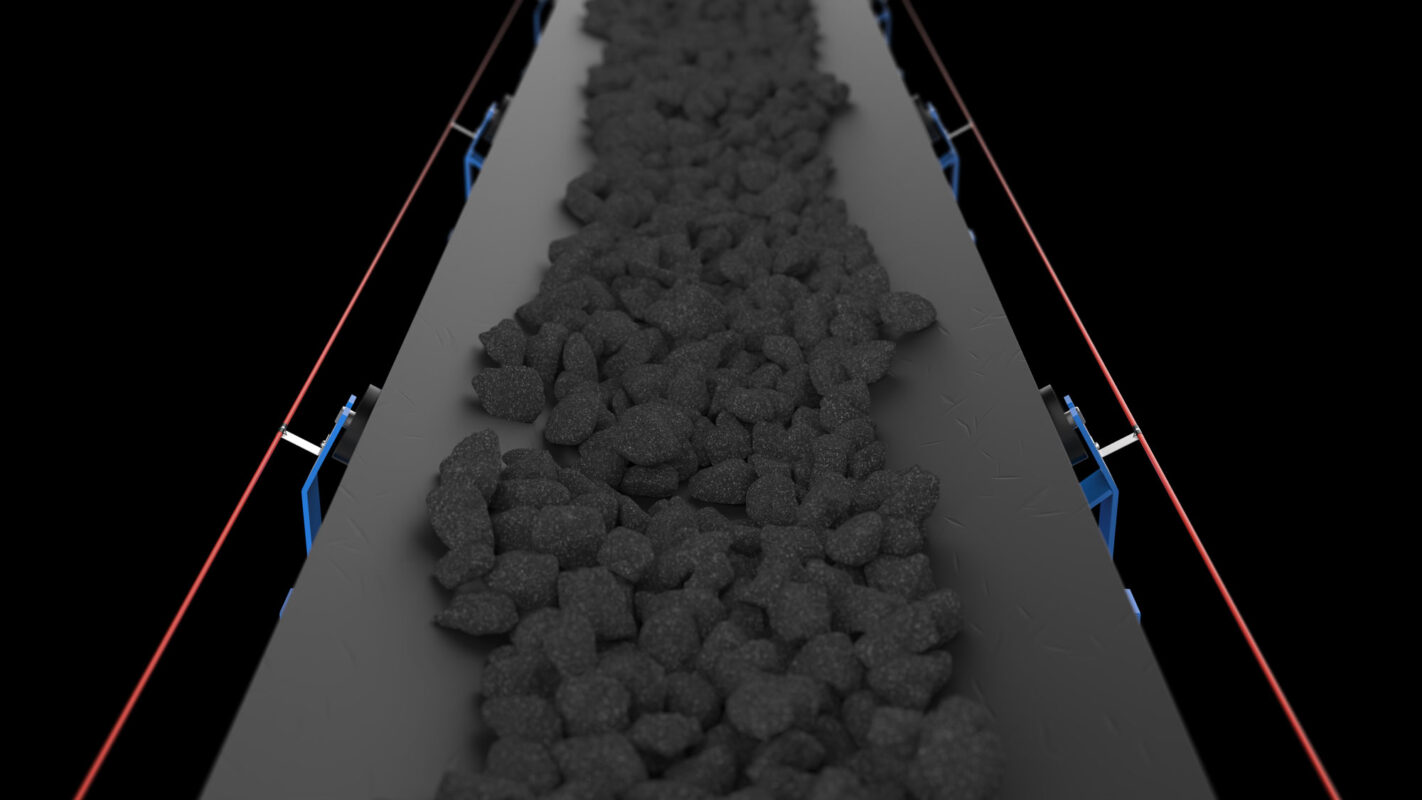

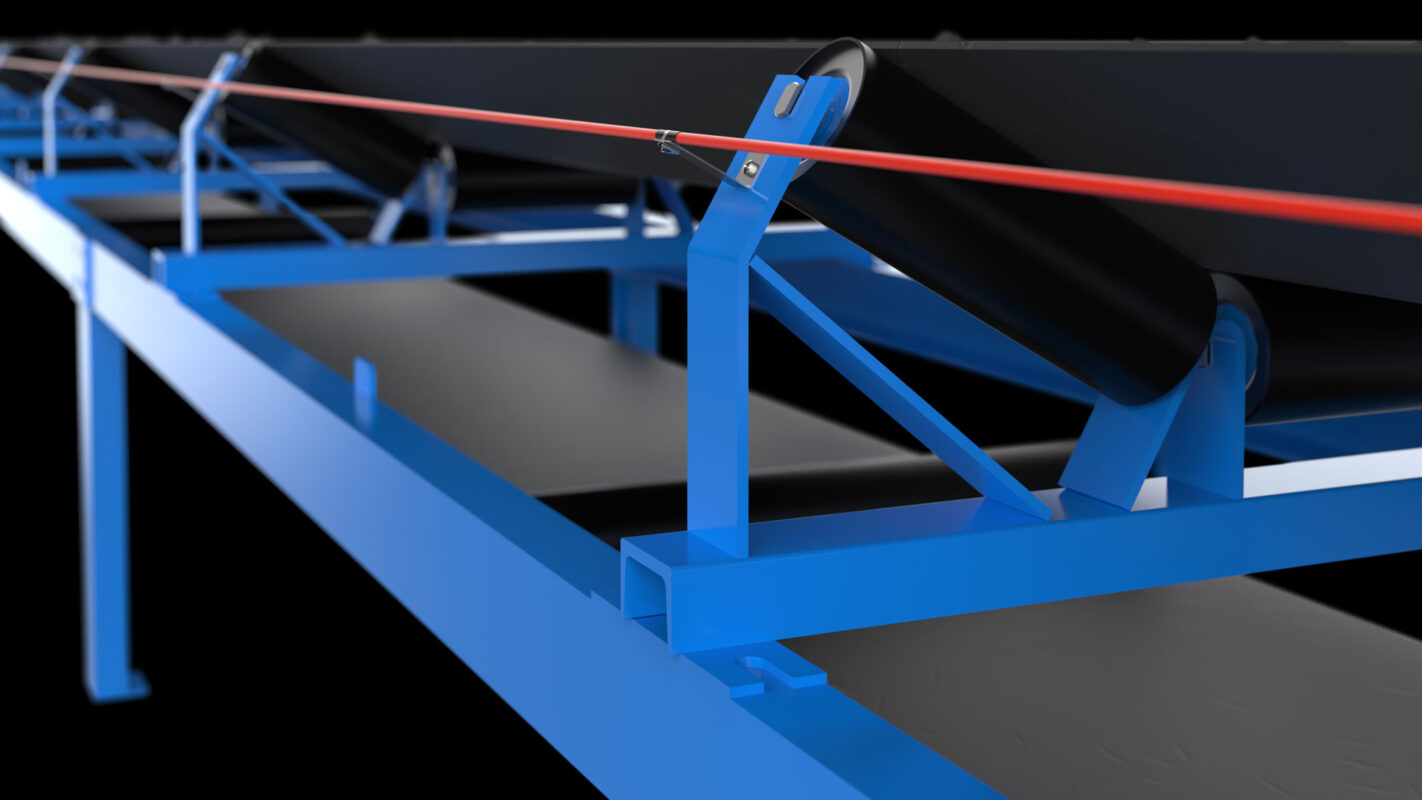

Typical Installation

FyreLine linear heat cable can be easily installed in any conveyor system. Heat sensing cable should be installed on each side of the rollers to enable the detection system to identify and locate a fire at any point along the belt. An additional cable should also be installed around one and a half metres above the centre of the belt to detect fire when the system is stationary.

Typical Wiring Diagram

Handpicked Products for a Conveyor Belt

FyreLine EN54 Fixed Linear Heat Detection System

The FyreLine EN54 Fixed Controller is a dual zone module capable of monitoring up to two zones of FyreLine EN54 Fixed Linear Heat Detection (LHD) Cable. It monitors the cable for overheat conditions and automatically calculates and displays the distance along the cable to the alarm point when an event is triggered. Each zone of the FyreLine EN54 Fixed controller can operate either independently of each other, or in interlock mode.

The ProFyre range of power supplies employ state-of-the-art switch mode power technology to provide a continuous and reliable source of 24V DC power to meet the technical and legislative requirements of the professional fire detection and alarm industry/installer.

FyreLine EN54 Fixed Linear Heat Detection Cable is a non-resettable line-type heat detector. It uses fixed temperature detection technology to provide a simple method of sensing changes in temperature. With a temperature rating of either 78°C or 88°C, FyreLine EN54 heat sensing cable is suitable for a wide range of applications and environments.

The FyreLine EN54 Fixed End of Line is designed to effectively terminate up to two zones of FyreLine EN54 Fixed Linear Heat Detection Cable in a secure, weatherproof enclosure. It has built-in switches to simulate fault or alarm conditions to allow the system to be fully tested in situ. It is particularly useful for when the system is used in interlock mode to prevent false alarms. In this mode, two fixed LHD cables are run side-by-side and an alarm is only activated on the fire alarm control panel when both cables trigger.

Linear Heat Detection Cable Mounting Clips & Accessories

The L-Clip can be used to support FyreLine EN54 Fixed Linear Heat Detection Cable below or above the risk. They are most commonly used on flat mounting surfaces and are available in zintec or stainless steel.

Why Choose Eurofyre?

- Complete System Supplier

- Eurofyre manufactures and supplies all aspects of fire detection including linear heat detection and its associated products and can provide expert advice and consultation.

- Demonstration and Training

- We offer demonstrations and expert training on a range of systems, including FyreLine linear heat detection systems, in our very own sophisticated training facility.

- After-Sales Support

- Eurofyre offers both on-site and telephone support to assist you in ensuring that your system is fully functional and operating at maximum efficiency. Our after-sales care and support are second to none.

For more information about EN54 Fixed Linear Heat Detection, or to discuss any of the other products that Eurofyre has to offer, please feel free to get in touch either by phone on +44 (0) 1329 835 024, by email to [email protected] or via the online enquiry form situated on our contact page.

Don’t forget you can follow us on LinkedIn, Twitter and Facebook or sign up to our newsletter (in the footer below) to receive all the latest information from Eurofyre.