Key Features

- UL 521 approved and compliant with the EN54:22 draft standard

- Self-restorable analogue type system with optional pre-alarm setting

- Cable based sensing allows detection at the point of risk

- Low installation, maintenance and repair costs

- Reliable solution for hazardous areas

Overview

Polypropylene is the least common option and, although it is tougher than PVC, is mainly used for applications where strong acids are present or in corrosive environments.

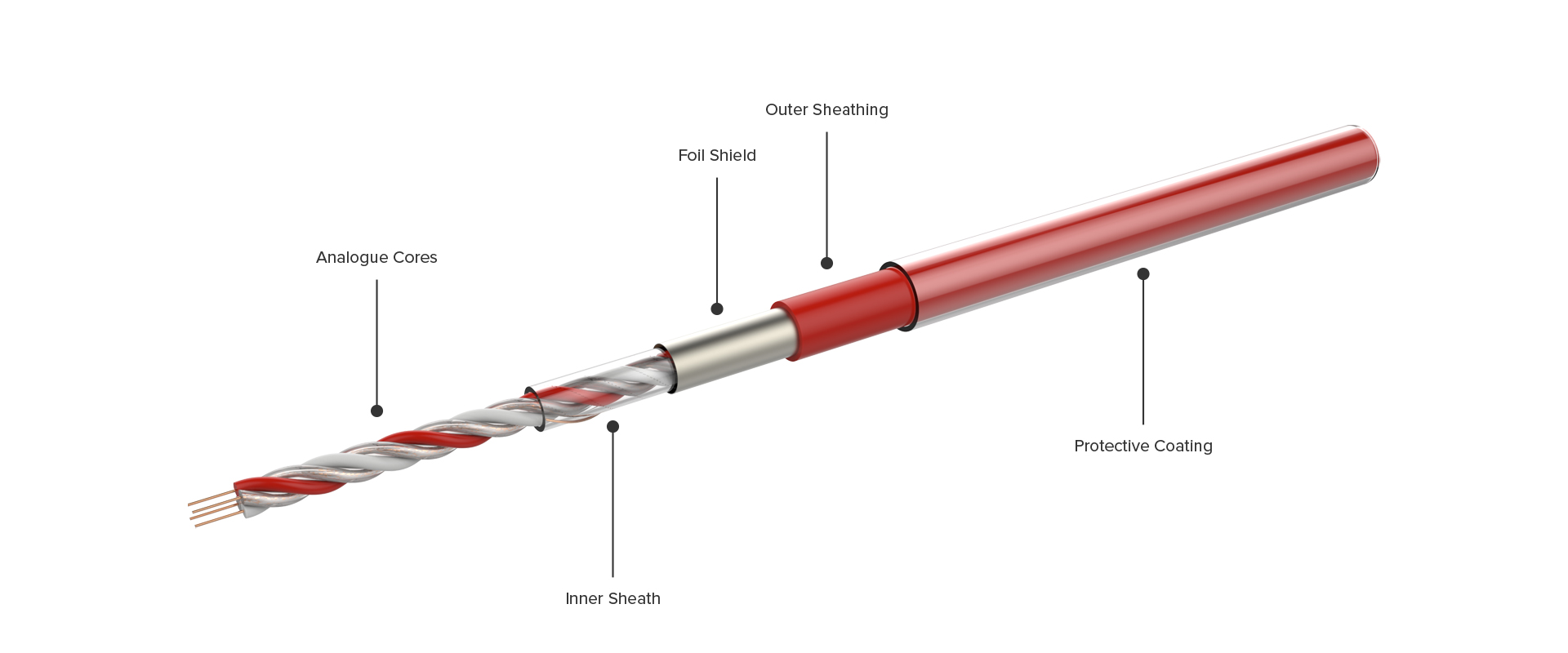

Sensing Cable Construction

FyreLine Analogue Linear Heat Detection cable is constructed using a pair of copper conductors coated in a temperature sensitive polymer whose resistance changes as a function of temperature. A calibration resistance (white) and average ambient temperature sensor (red) core are also twisted with the two original conductors. A foil shield and protective outer coat is extruded over the twisted core.

Approvals

The FyreLine analogue linear heat detection cables are fully approved by the Underwriters Laboratories (UL) and bears the CE mark to show that they comply with all the applicable Directives including the CPR, EMC and the Low Voltage Directive (LVD).

- UL 521

Heat detectors for fire protective signaling systems.

Tech Specs

| Outer Jacket | Clear Polypropylene |

| Overall Diameter | 4.57mm ± 0.075mm (0.180” ± 0.003”) |

| Humidity | 0% to 99% RH |

| RFI Shielding | Twisted and foil shielding to reduce inductance and RF susceptibility |

| Cores | Calibration Resistance: White Sensor Core: Red Conductor & Specially Doped Polymer Core: Clear Conductor & Specially Doped Polymer Core: Clear |

| Maximum Continuous Length | 500m (1640ft) |

| Minimum Continuous Length | 30.5m (100ft) |

| Operating Temperature Range | -40ºC to 125ºC |

| Continuous Ambient Temperature Range | -40ºC to 90ºC |

Downloads

- FyreLine Analogue Polypropylene LHD Cable Datasheet

- FyreLine Analogue Technical Sales Brochure

- FyreLine Analogue Linear Heat Detection System Guide

- FyreLine Analgoue Approval Certificate (UL)