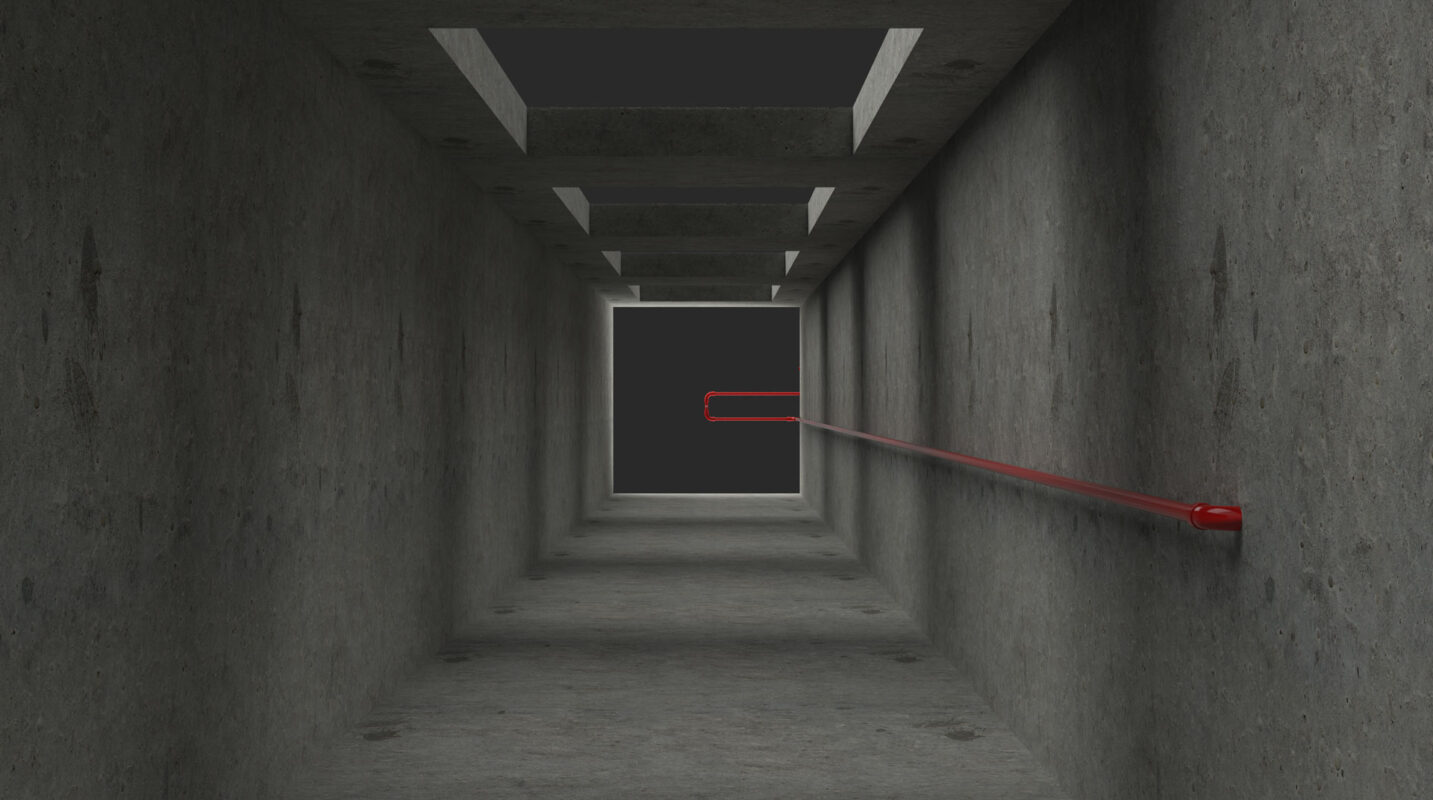

Lifts, or elevators, provide a fast and safe method for people to reach levels of a building. Lifts are typically enclosed in shafts and rise vertically through a building. Lifts are found in most multi-storey buildings such as offices, factories, hotels, flats and more.

In previous years, lifts were to be avoided during fire events, however, more recently they have been considered as an effective way for occupants to evacuate upper levels and as a quick method for firefighters to ascend a building. This is largely due to the advances in fire safety and smoke detection technologies.

Early and reliable detection of fire or smoke in the lift shafts is critical for the safe evacuation of building occupants. However, there are some unique risks and challenges to consider when designing a suitable fire detection system.

What are the Risks?

Despite technological advances that have made lifts safer to use in fire events, there are still a number of risks. These include:

- Transportation

- Lift shafts act as vertical channels for the spread of heat, smoke and toxic gases.

- The Piston Effect

- The piston effect is when lift car motion causes transient pressure inside the shaft. This will enable smoke to enter the shaft and spread to other floors.

- Trapped Occupants

- If the lift is to shut down due to the fire event, occupants may get trapped.

- Electrical Faults

- Lift shafts often contain lots of electrical wiring. If electrical cables are damaged or develop a fault, they may catch fire.

- Mechanical Malfunction

- Lifts rely on a plethora of moving parts. Faults or poor maintenance can lead to increased friction, overheating and fire.

What are the Challenges?

Lift shafts also present more challenges than most environments. These include:

- Dust and Contamination

- Dust and other contaminants can affect the reliable operation of fire and smoke detection systems.

- Maintenance

- Access for maintenance can be extremely difficult if the component that needs attention is in the lift shaft. Therefore, traditional type detectors would not be suitable.

- Downtime

- Lifts are often heavily relied on. Therefore, if they need to be shut down for maintenance then the time they are out of operation must be kept to a minimum.

- Airflow

- The piston effect, stack effect and wind effect can all increase dispersion and dilution of smoke. This makes detection challenging.

- Lift shafts often contain multiple moving parts. These can create an obstruction and lessen the effectiveness of a fire alarm or smoke detection systems.

Why Use FAAST FLEX?

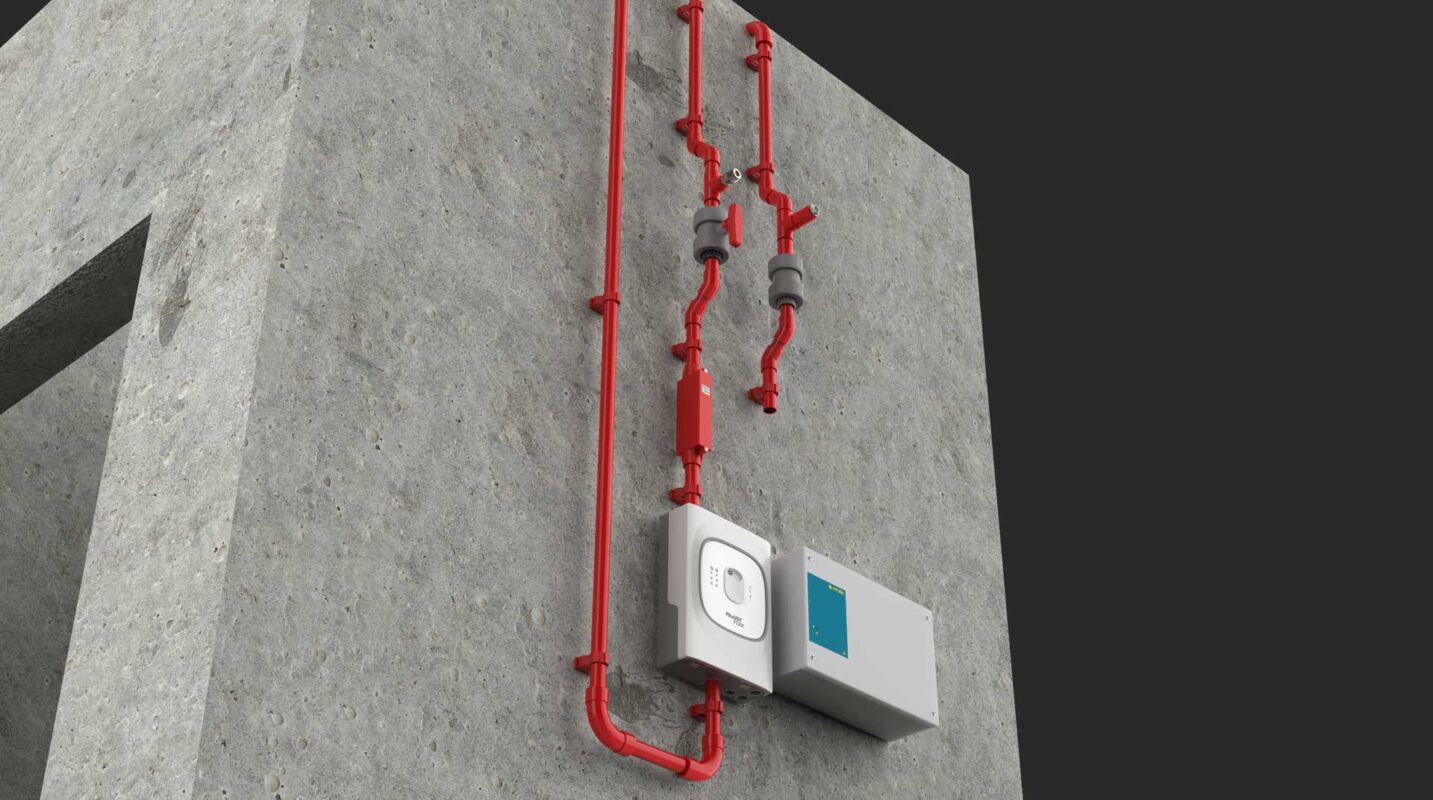

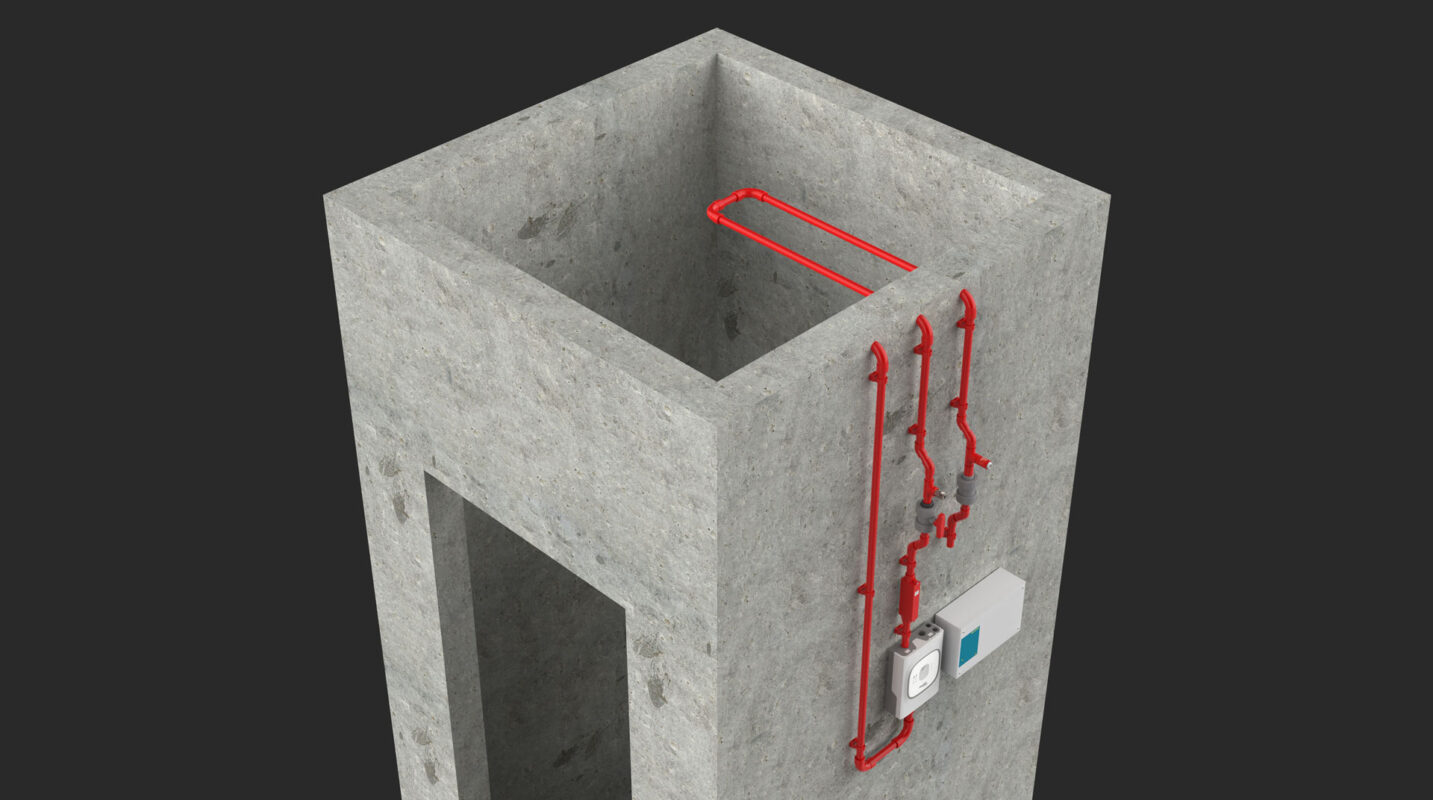

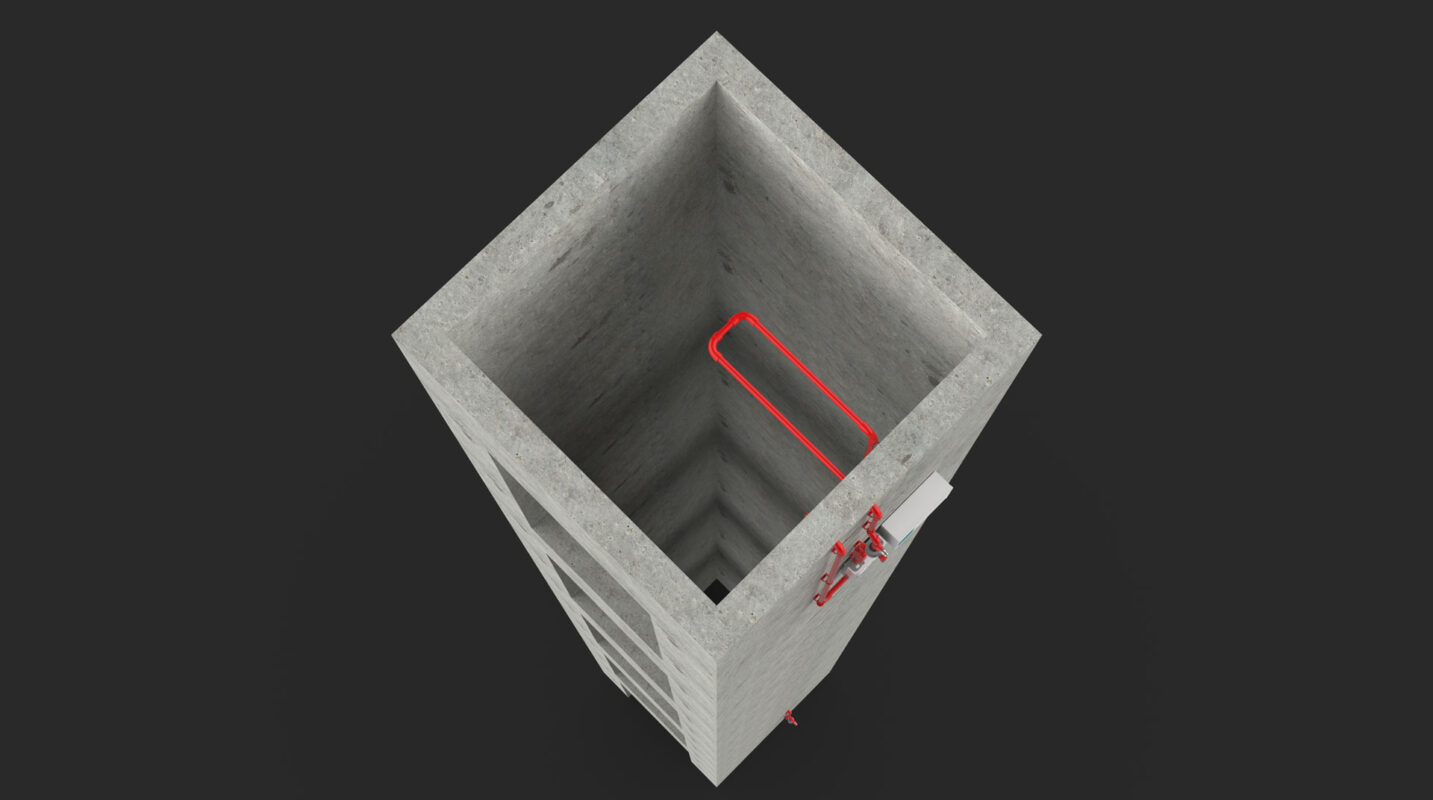

FAAST FLEX aspirating smoke detectors deliver flexible and cost-effective smoke detection for a variety of different applications such as lift shafts, small to medium-sized warehouses, ceiling voids, cold storage facilities and more.

FAAST FLEX’s powerful aspirators can accommodate the varying air flows that are present in the lift shaft while multiple sampling holes deliver increased flexibility and performance.

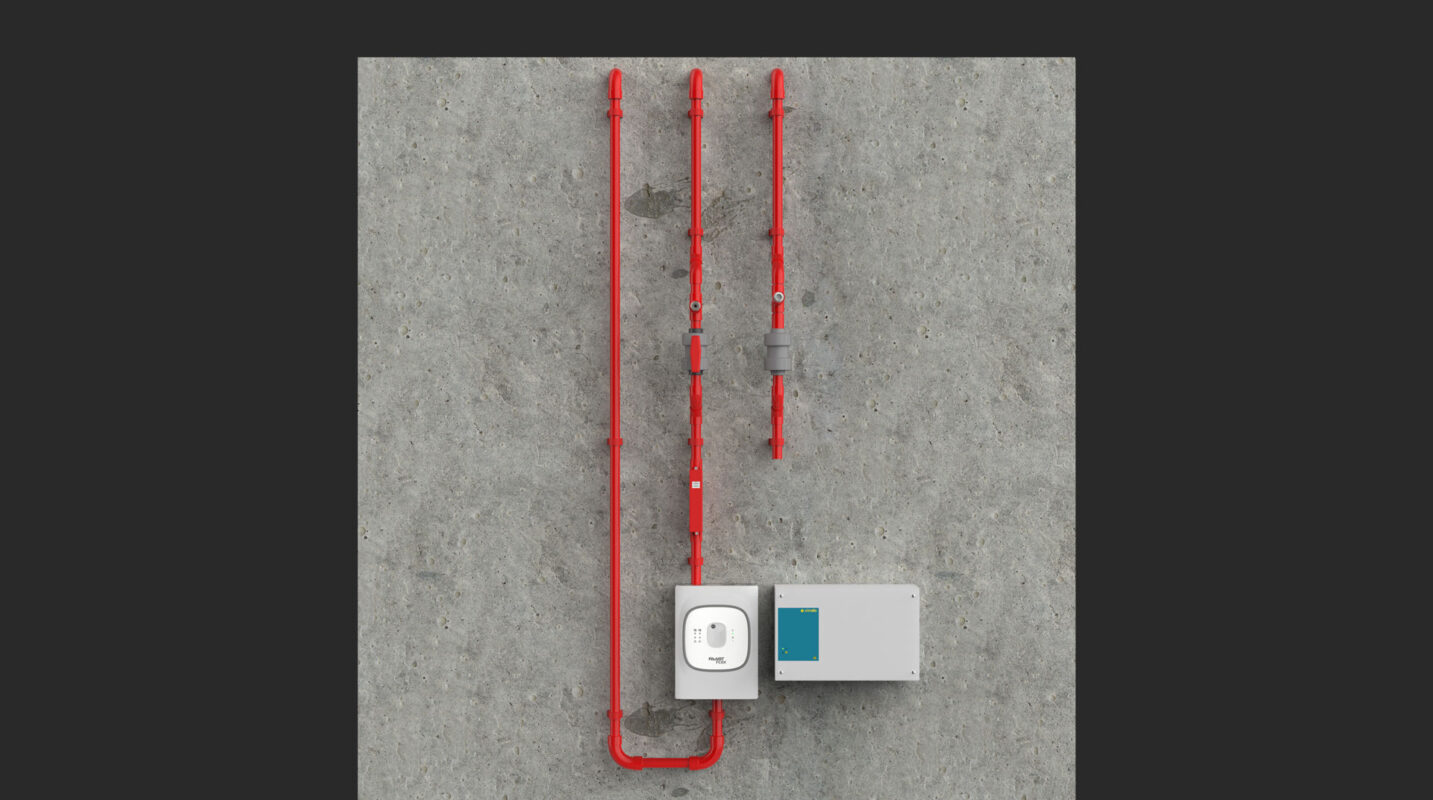

They can be mounted in a location external to the lift shaft to provide easy access for maintenance and testing. This also means that, in most cases, the lift can continue to operate while these tasks are performed. This also eliminates the need to have a lift technician present. A particle filtration system is also included in the design to ensure reliable operation when there are high levels of contamination.

FAAST FLEX aspirating smoke detectors can also be configured and monitored via Bluetooth.

All of the above makes FAAST FLEX extremely suited to provide fast and reliable smoke detection for lift shafts that enables the possibility of using lifts as part of the evacuation process.

Key Features

- One or Two-channel Version Available

- Out-of-the-Box Operation

- Bluetooth Interface

- Modular Design

- Field-Replaceable Components

There are three classes of sensitivity as listed by EN54-20. These sensitivity classes are to help with the variety of applications aspirating smoke detection can be used for and ensure that the most appropriate aspirating smoke detector is selected for the proposed application/area. FAAST FLEX can be configured to suit all three sensitivity classes.

FAAST FLEX Design Considerations

When designing an aspirating smoke detection system for lift shafts, it is important to take into account all the varying factors that will affect the performance of the system. These include pipe network design, pressure differential, contamination and maintenance.

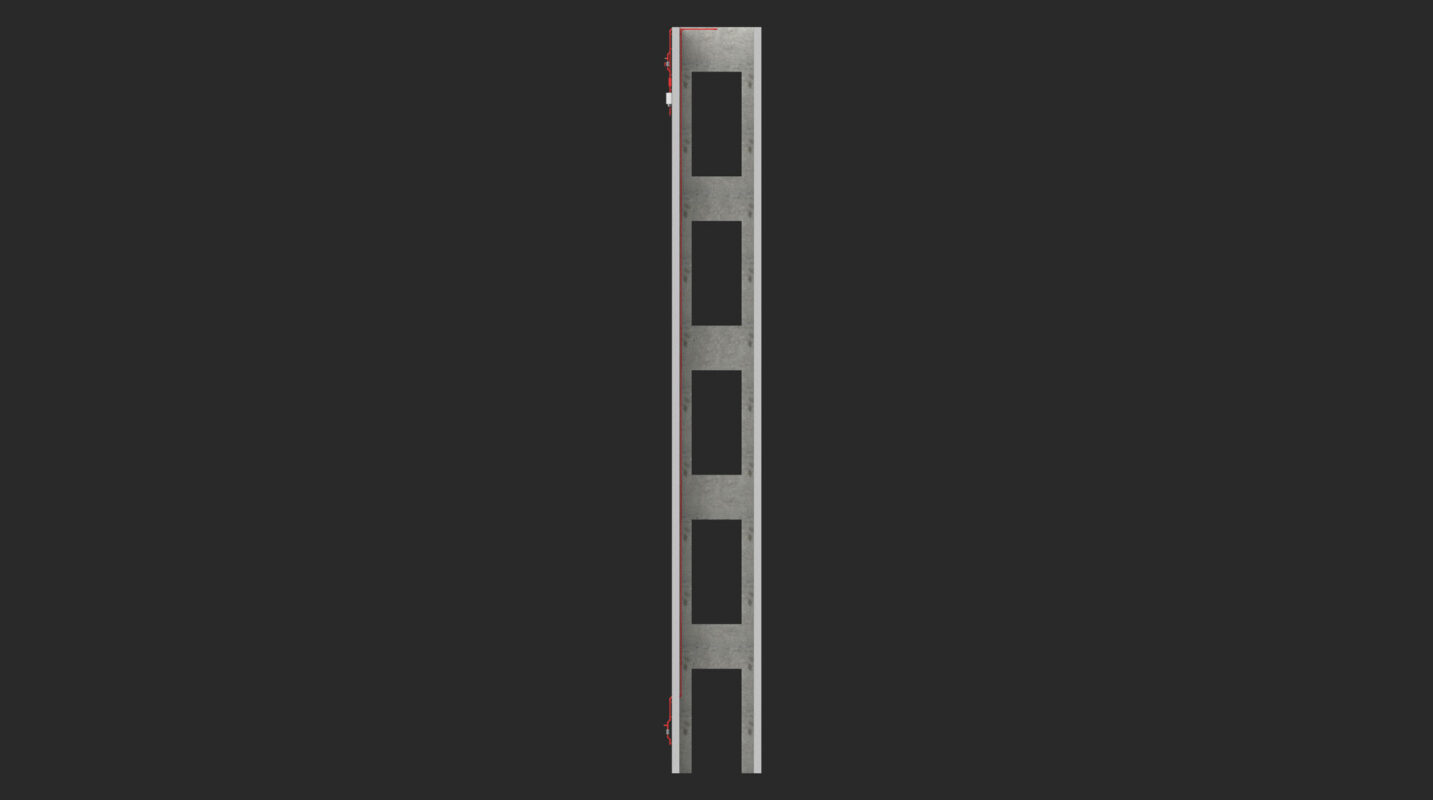

Typical Sampling Pipe Network

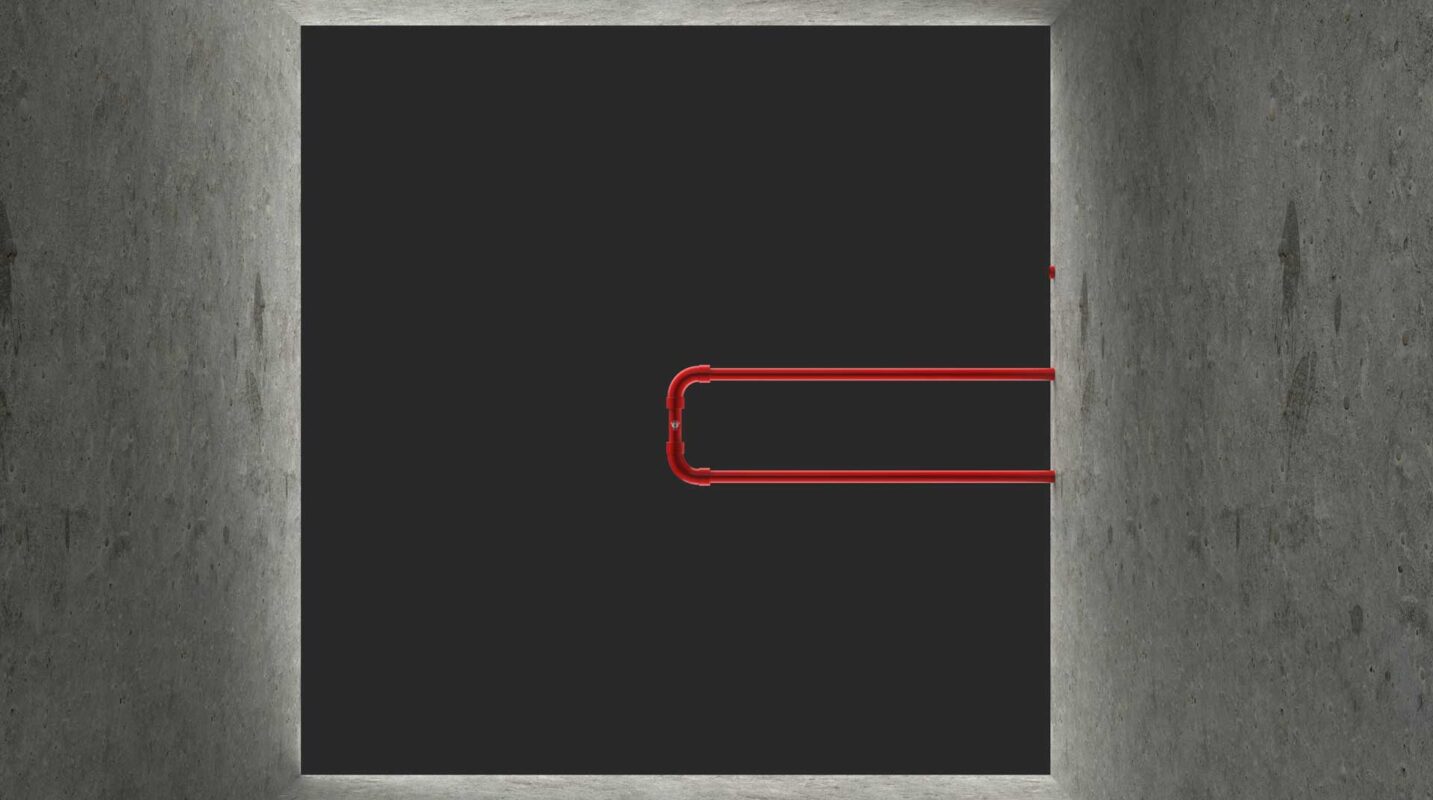

For buildings up to four floors, it is recommended that sampling holes are placed at the top of the shaft and upstream from smoke vents if present. Sample points should have a 30° orientation to the direction of the air flow across the vent.

For buildings greater than four floors, it is recommended that sampling points are positioned at the top of the shaft and at each floor level. Sampling points along the shaft should be placed at one corner of the shaft approximately 0.5m above the height of the elevator door.

Lift Shaft Pressure Differential

It’s important to consider transient pressure differentials caused by the elevator piston effect, stack effect (normal, reversed) and wind effect when designing a smoke detection system for lift shafts. To overcome these issues it is recommended that the detector’s exhaust pipe is directed back into the shaft with the open-end pipe facing downward and that a delay is applied for the flow alarm signal (alarm delay determined on a case-by-case basis depending on speed of elevator car, presence of pressure relief vents, leakage).

Contamination

FAAST FLEX detectors incorporate an internal mesh filter to reduce contamination. However, in shafts that experience particularly high levels of contamination, it is recommended that an Xtralis In-Line Filter is also used.

VESDA In-Line Filters improve detector longevity and reduce maintenance frequency. VESDA filters have a tapered inlet and can easily be fitted in-line with the sampling pipe without the need for additional pipe fittings. This keeps the cost of installation at an absolute minimum. The in-line filter should be placed in an accessible location for easy access for maintenance.

Maintenance

Maintenance of the FAAST FLEX system is performed at an accessible location. With regard to sample pipe network, smoke transport time tests can be performed through a “maintenance test hole” at an accessible location by extending the sample pipe outside the shaft.

Test Point

Air sampling test points allow for functional smoke testing of aspirating smoke detection systems and are typically located at the end of a sampling pipe network.

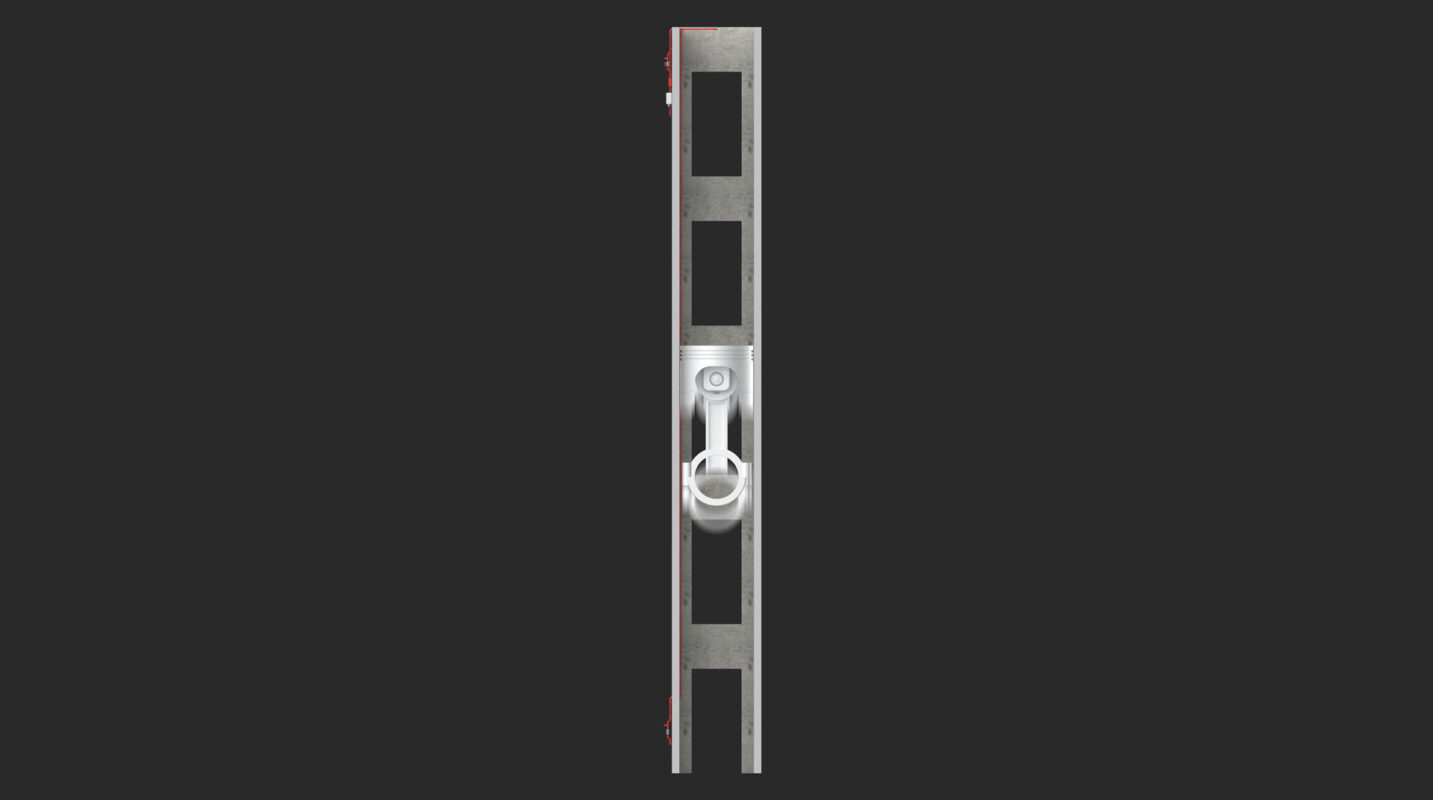

Compressed Air Cleaning

Sampling holes inside the shafts can be cleaned with compressed air; the frequency of cleaning will depend on the contamination level of the shaft. The VESDA 25mm Quick Release Airline Assembly is used to aid this process. When installed close to the aspirating smoke detector, the quick-release airline can be used to shut the air off to the detector while the compressed air delivery system can be easily and quickly connected to the quick-release connectors. This allows the air to be effectively blown through the system without damaging the detector.

It is essential that a spring loaded air release valve is installed at the far end of the air sampling pipe run to prevent back-flow from an air-compressed pipe. This will automatically open to release excess pressure during the cleaning process.

Why Choose Eurofyre?

- Xtralis Gold Partner

- Eurofyre has ‘Gold Channel Partner’ status with Xtralis – the market leader in aspirating smoke detection. This recognition displays our level of commitment, including excellent customer service and competitive pricing.

- Complete System Supplier

- Eurofyre is a complete system supplier and has been a major Xtralis technical wholesaler since 2007. This means we can offer expert advice and supply all aspects of fire detection including aspirating smoke detection systems, conventional and addressable fire alarm control panels and linear heat detection.

- Pipework Design

- Eurofyre can also provide assistance with aspirating pipe network design to ensure optimum network performance and installation quality.

- Demonstration and Training

- We have a sophisticated training facility where we offer demonstrations and expert training on a range of systems, including VESDA-E aspirating smoke detection systems.

- After-Sales Support

- Eurofyre prides itself on providing after-sales care and support that is second to none. We offer both on-site and telephone assistance to help you ensure that your system is fully operational and working at its best.

For more information about VESDA aspirating smoke detection, or to discuss any of the other products that Eurofyre have to offer, please feel free to get in touch either by phone on +44 (0) 1329 835 024, by email to [email protected] or via the online enquiry form situated on our contact page.

Don’t forget you can follow us on LinkedIn, Twitter and Facebook or sign up to our newsletter (in the footer below) to receive all the latest information from Eurofyre.