Key Features

- UL 521 approved

- Cable based sensing allows detection at the point of risk

- Low installation, maintenance and repair costs

- Reliable solution for hazardous areas

- Low material cost

Overview

The stainless steel braided linear heat detection cable provides the ideal solution for areas where the cable may be accidentally cut or where it may be subject to mechanical abrasion.

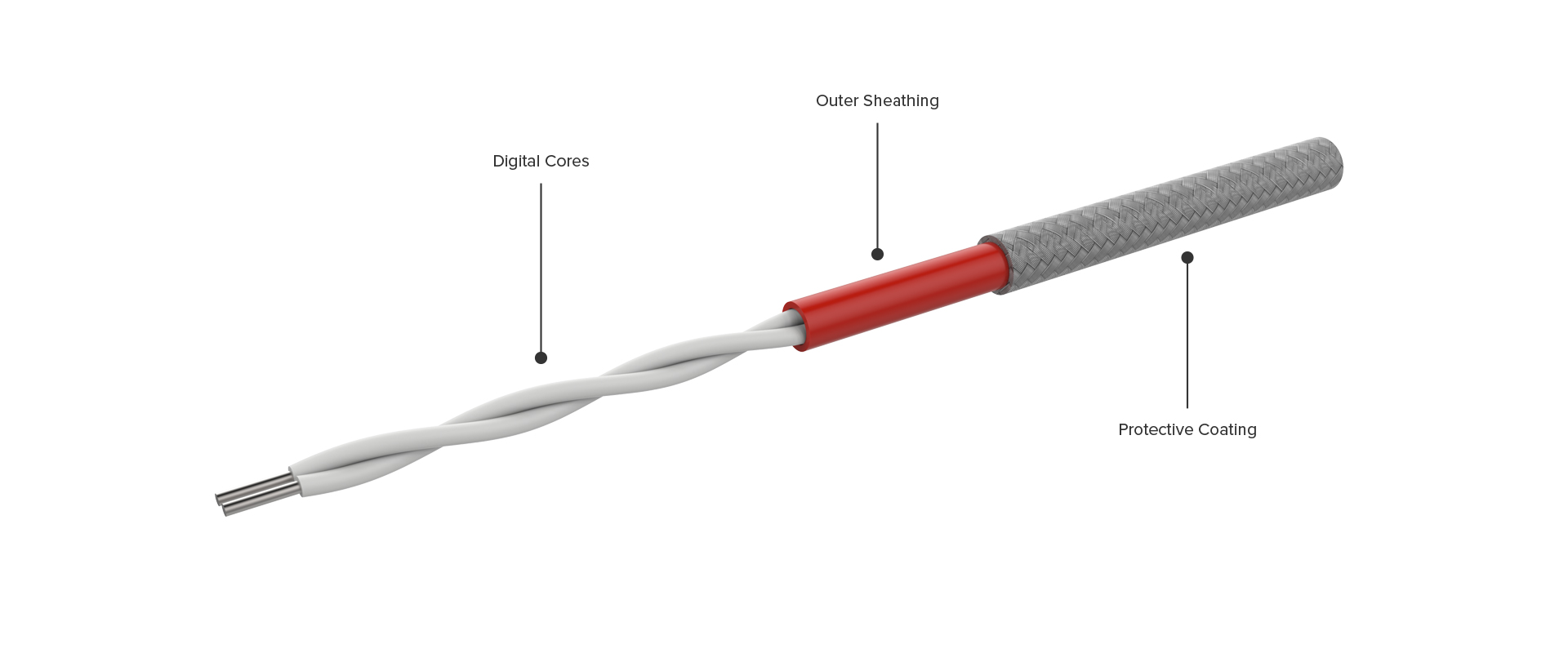

Sensing Cable Construction

FyreLine linear fixed heat sensing cable is constructed using two twisted and tensioned, tri-metallic conductors. Each of the conductive cables are coated in a heat sensitive polymer which, when heated to its rated temperature, melts, causing the two cables to touch. The resulting short sends a signal to the fire alarm control panel, indicating that a fire (or excessive heat) has been detected. Once a fire has been detected the damaged length of cable is easily replaceable.

Approvals

The FyreLine digital linear heat detection cables are fully approved by the Underwriters Laboratories (UL) and bears the CE mark to show that they comply with all the applicable Directives including the CPR, EMC and the Low Voltage Directive (LVD).

- UL 521

Heat detectors for fire protective signaling systems.

Tech Specs

| Construction | Overall insulated, twisted pair of tri-metallic cores |

| Insulation | 1kV tested protective outer coat |

| Approvals | CE Marked, UL Listed |

| Maximum Zone Length | 3,000m (10,000ft) |

| Overall Diameter | 4.50mm ± 0.12mm (0.177” ± 0.005”) |

| Minimum bend radius | 50mm (2”) |

| Max Voltage Rating | 30Vac, 42Vdc |

| Resistance | ~100Ω/km (29Ω/kft) per leg |

| Velocity of Propagation | ~55% |

| Capacitance | 88 – 150 pF/m (26 – 45 pF/ft) |

| Inductance | 540 – 1050 nH/m (165 – 320 nH/ft) |

Downloads

- FyreLine Digital Stainless Steel LHD Cable Datasheet

- FyreLine Digital Technical Sales Brochure

- FyreLine Digital Linear Heat System Guide

- FyreLine Digital Approval Certificate (UL)