Key Features

- Wide sensitivity range

- Laser-based smoke detection

- High-efficiency aspirator

- Airflow supervisor per sampling pipe

- 7 programmable relays

This product has been discontinued and has been replaced by the VESDA-E VEP Aspirating Smoke Detector. Please contact Eurofyre further information, spare parts, servicing and training.

Overview

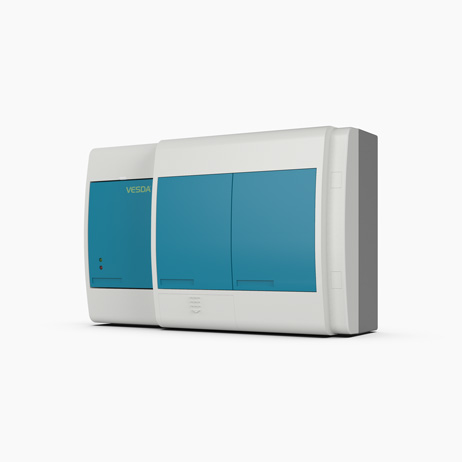

The Xtralis VESDA VLP Aspirating Smoke Detectors is classed as a “Very Early Warning Smoke Detector”. This means that it can accurately measure very low to extremely high concentrations of smoke and can reliably detect fire at the earliest stage possible.

The VESDA VLP Aspirating Smoke Detector is the central element of the VESDA ASD product range and uses unique detection properties to provide an alarm sensitivity range of 0.0005% to 20% obscuration/m (0.0015%–6.25% obscuration/ft).

How it Works

A high-efficiency aspirator is used to draw air into the VLP via a network of sampling pipes. Each pipe has its own sensor that monitors for changes in airflow to ensure optimum performance, a sample of air is sent to the detection chamber and the rest is exhausted back into the protected zone. The air passed into the sampling chamber is filtered by ultra-fine filters to protect the optical surfaces inside the detector from contamination.

The detection chamber employs carefully positioned sensors and a stable Class 1 laser light source to provide maximum response to a broad range of smoke types.

All alarm, service and event fault, along with the status of the detector are transmitted to displays and external systems via VESDAnet.

VESDAnetTM

VESDAnet™ is VESDA’s fault-tolerant communications protocol. VESDAnet provides a robust bi-directional communication network between all VESDA devices and can even provide continued operation during single point wiring failures. VESDAnet also introduces the possibility to the system to be programmed from a single location and forms the basis of the modular nature of the VESDA system.

AutoLearnTM

AutoLearn is a unique software tool that monitors the ambient environment and sets the most suitable alarm thresholds (Alert, Action, Fire 1, Fire 2) during the commissioning process. This allows the system to produce the earliest possible warning of a potential fire event while reducing the likelihood of nuisance alarms.

Referencing

Referencing by VLP detectors makes sure that external pollution does not interfere with the true smoke level that is detected in the protected areas. This is particularly important in areas that employ air handling systems that may be affected by pollution external to the controlled environment. Referencing allows the system to safely compensate for this transient state to provide continued detection without nuisance alarms.

Other Features

- Four configurable alarm levels

- Four inlet pipes

- Event log

- Easy to replace air filter

- Modular design

- Recessed mounting option

- Clean air barrier optics protection

Approvals

The VESDA VLP is fully approved by VdS for safe use and installation in any European Union country and bears the CE mark to show that it complies with all the applicable Directives including the CPR, EMC and the Low Voltage Directive (LVD).

EN54-20:2006 + AC:2008 – Fire detection and fire alarm systems – Control and indicating equipment.

Tech Specs

| Supply Voltage | 18–30Vdc |

| Power Consumption @ 24Vdc | No Display or Programmer Aspirator @ 3000rpm Power: Quiescent – 5.8W, With alarm – 6.96W Current: Quiescent – 240mA With alarm – 290mA Aspirator @ 4200rpm Power: Quiescent – 8.16W, With alarm – 9.36W Current: Quiescent – 240mA With alarm – 290mA |

| Dimensions (W x H x D) | 350mm x 225mm x 125mm (13.8in x 8.9in x 4.9in) |

| Weight | 4.0kg (9 lbs) including Display and Programmer modules |

| IP Rating | IP30 |

| Operating Conditions | Tested to: -10°C to 55°C (14°F to 131°F) Product UL listed for use from 0°C to 38°C (32°F to 104°F). Detector Ambient: 0°C to 39°C (32° to 103°F)* (Recommended) Sampled Air: -20° to 60°C (-4° to 140°F) Product UL listed for use from 0°C to 38°C (32°F to 104°F). Humidity: 10%–95% RH, non-condensing Please consult Eurofyre for operation outside these parameters or where sampled air is continually above 0.05% obs/m (0.015% obs/ft) under normal operating conditions. |

| Storage Conditions (non-operational) | Battery life: Up to 2 years Humidity: Dry (<95%) Temperature: 0° to 85° C Must not exposed to sunlight or other radiation sources |

| Sample Holes | EN 54-20: Class A (30 holes / 0.05% obs/m) Class B (60 holes / 0.06% obs/m) Class C (100 holes / 0.08% obs/m) |

| Sampling Network | Aggregate pipe length: 200m (650ft) Maximum Single Length: 100m (328ft) Minimum flow per pipe: 15 liters/min. Pipe Modelling Design Tool: ASPIRE2™ These pipe lengths represent best practice for systems with single pipe runs on each port (no branching). For longer and/or more complex pipe arrangements, predictions of EN 54-20 compliance are determined using ASPIRE2. |

| Area Coverage | Typically up to 2000m2 (21500 sq. ft.), depending on local codes and standards |

| Pipe Size | External Diameter 25mm (1 in) Internal Diameter 15–21mm (9/16 in–7/8 in) |

| Programmable Relays | 7 Relays, Contacts rated 2A @ 30Vdc NO/NC Contacts |

| Cable Access | 8 x 25mm (1in) knockouts in various positions |

| Cable Termination | Screw terminals 0.2–2.5 sq mm (30–12 AWG) |

| Alarm Sensitivity Range | 0.005%–20% obs/m (0.0015%–6.25% obs/ft) |

| Alarm Threshold Setting Range | Alert: 0.005%–1.990% obs/m (0.0015%–0.6218% obs/ft) Action: 0.010%–1.995% obs/m (0.0031%–0.6234% obs/ft) Fire 1:0.015%–2.00% obs/m (0.0046%–0.625% obs/ft) Fire 2:0.020%–20.00% obs/m (0.0062%–6.25% obs/ft) Limited to 12% obs/m (4% obs/ft) in UL mode |

| Event Log | Up to 18,000 events stored on FIFO basis |

| AutoLearn | Minimum 15 minutes, maximum 15 days. Recommended minimum period 1 day. During AutoLearn thresholds are NOT changed from pre-set values. |

| Software Features | Referencing: Compensation for external ambient conditions. Four Alarm Levels: Alert, Action, Fire 1 & Fire 2. Two Fault Warning Levels: Maintenance and Major fault. Software Programmable Relays: 7. Maintenance Aids: Filter & Flow monitoring. Event reporting via VESDAnet or Event Log. |

Downloads

Buy

Eurofyre is an authorised distributor of Honeywell and has been a major technical wholesaler of Xtralis products since 2007. We offer expert advice and supply all aspects of VESDA, FAAST and ICAM aspirating smoke detection systems including pipework calculations, demonstration/training and excellent after-sale support.

Contact us to receive competitive trade discounts or apply online for a credit account.

This product has been discontinued and has been replaced by the VESDA-E VEP Aspirating Smoke Detector, further information can be found here. Please contact Eurofyre for further information, spare parts, servicing and training.