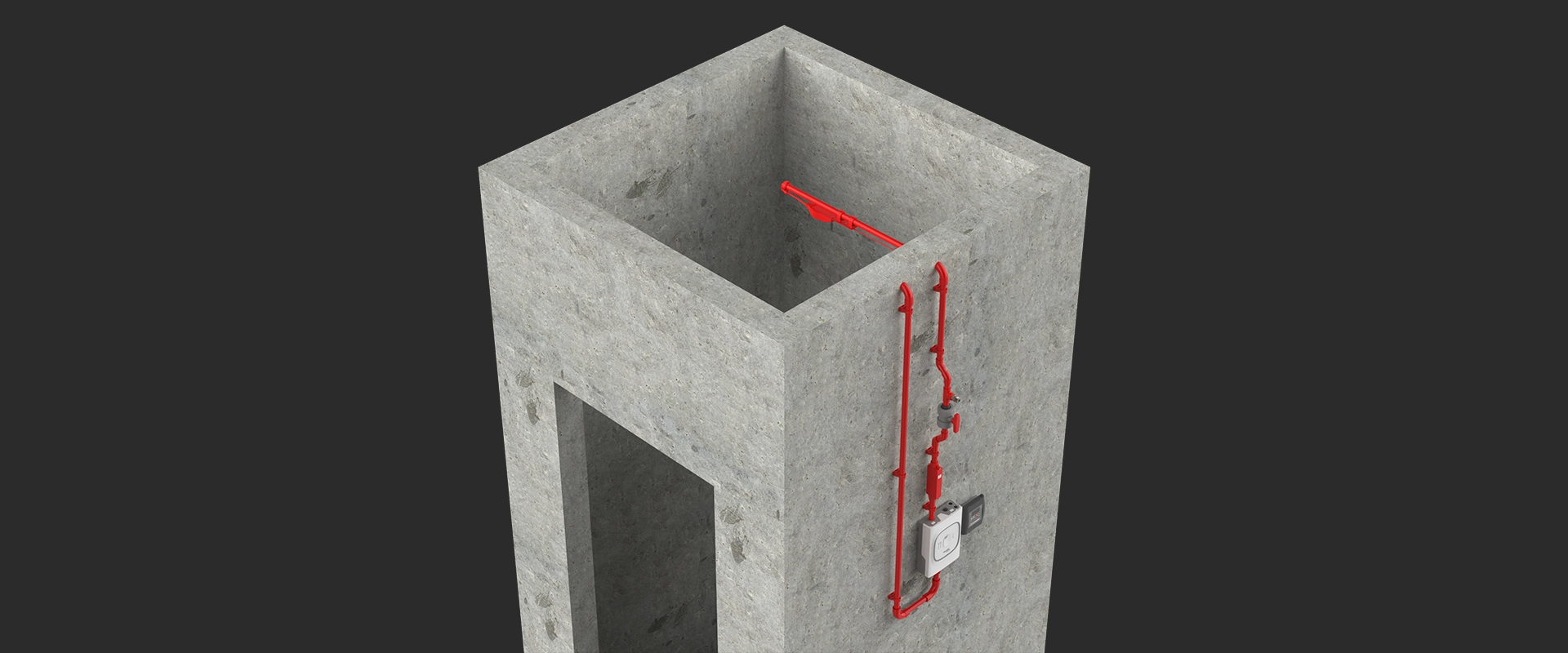

A lift shaft, or elevator shaft, is a vertical passageway within a building specifically designed to accommodate elevators or lifts. It serves as a conduit for the elevator’s movement, allowing it to traverse between different floors of a building.

The shaft typically includes guide rails, safety mechanisms, and electrical systems that facilitate the elevator’s operation. Its construction involves fire-resistant materials to enhance safety.

The lift shaft plays a crucial role in the efficient and safe transportation of people and goods within multi-story structures, serving as the core structural element that facilitates vertical mobility in modern buildings.

However, lift shafts can also come with a number of fire risks.

What are the Risks?

- Electrical Issues

- Electrical faults or failures within the lift system, such as faulty wiring, malfunctioning components, or short circuits, can generate sparks and heat, potentially leading to a fire.

- Mechanical Failures

- Mechanical failures in the elevator machinery, such as overheated or malfunctioning components, can produce friction and heat, which might result in a fire.

- Improper Maintenance

- Lack of regular maintenance and inspection of elevator systems can lead to wear and tear that increases the risk of mechanical or electrical failures and subsequent fires.

- Vertical Fire Spread

- Fire can spread vertically through the lift shaft, potentially affecting multiple floors of a building. This rapid vertical spread can make it challenging to control the fire and evacuate occupants from upper floors.

- Structural Integrity

- The intense heat generated by a fire in the lift shaft can compromise the structural integrity of the building, especially if the shaft is made of materials that weaken under high temperatures. This can lead to the collapse of the shaft or adjacent structures.

What are the Challenges?

The fire risks associated with lift shafts mean that it is imperative to ensure that suitable fire detection systems are in place. However, several challenges are presented when designing a suitable solution:

- Testing and Maintenance Accessibility

- Regular testing and maintenance are essential to ensure the ongoing functionality of a fire detection system in lift shafts. However, accessing and conducting tests or repairs in the confined and potentially hazardous environment of a lift shaft can be challenging.

- Elevator Movement

- Elevators are constantly in motion, which can create false alarms if not properly accounted for. The fire detection system must be designed to differentiate between normal elevator operation and a genuine fire emergency.

- Smoke and Heat Dynamics

- Smoke and heat generated during a fire can behave differently within a vertical shaft compared to horizontal spaces. Understanding the dynamics of smoke movement and heat transfer in a lift shaft is essential for effective detection.

- False Alarms

- Lift shafts can be dusty or have occasional air currents, leading to false alarms if the system is overly sensitive.

- Integration with Building Systems

- Ensuring seamless integration of the lift shaft fire detection system with other building systems, including the elevator control system and the central fire alarm system, is crucial for an efficient and coordinated response to fires.

The Advantages of Using Aspirating Smoke Detection in a Lift Shaft

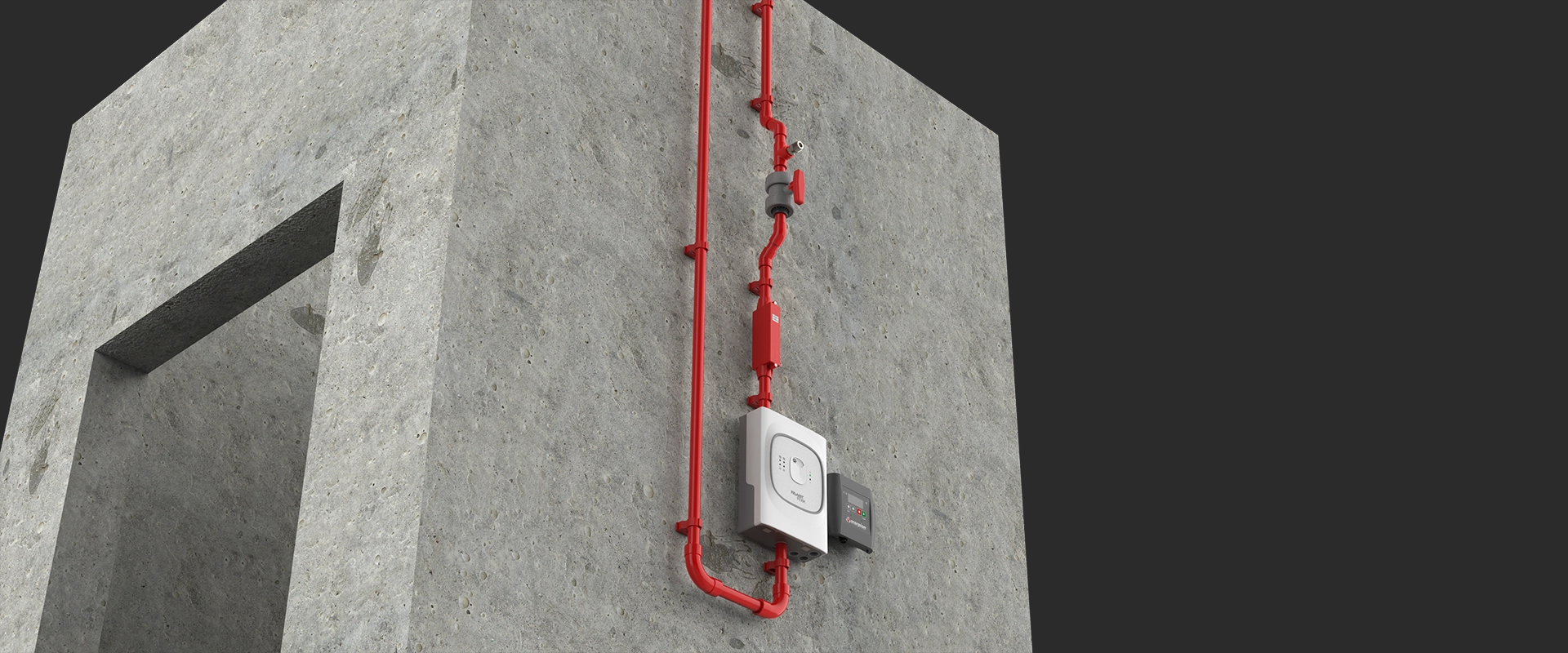

Aspirating smoke detectors, such as FAAST FLEX, can deliver flexible and cost-effective smoke detection for lift shafts.

FAAST FLEX’s powerful aspirators can accommodate the varying air flows that are present in the lift shaft while multiple sampling holes deliver increased flexibility and performance.

These detectors can be installed in a location outside of the lift shaft to provide easy access for maintenance and testing. This also means that, in most cases, the lift can continue to operate while these tasks are performed. A particle filtration system is also included in the design to ensure reliable operation when there are high levels of contamination.

Compliant Functional Smoke Test Method

Functional smoke testing is essential for ensuring the proper operation of smoke detection systems, particularly in challenging environments like lift shafts. Traditionally, the local area test point method is commonly used due to its cost-effectiveness. However, the introduction of the Scorpion system has brought significant advantages.

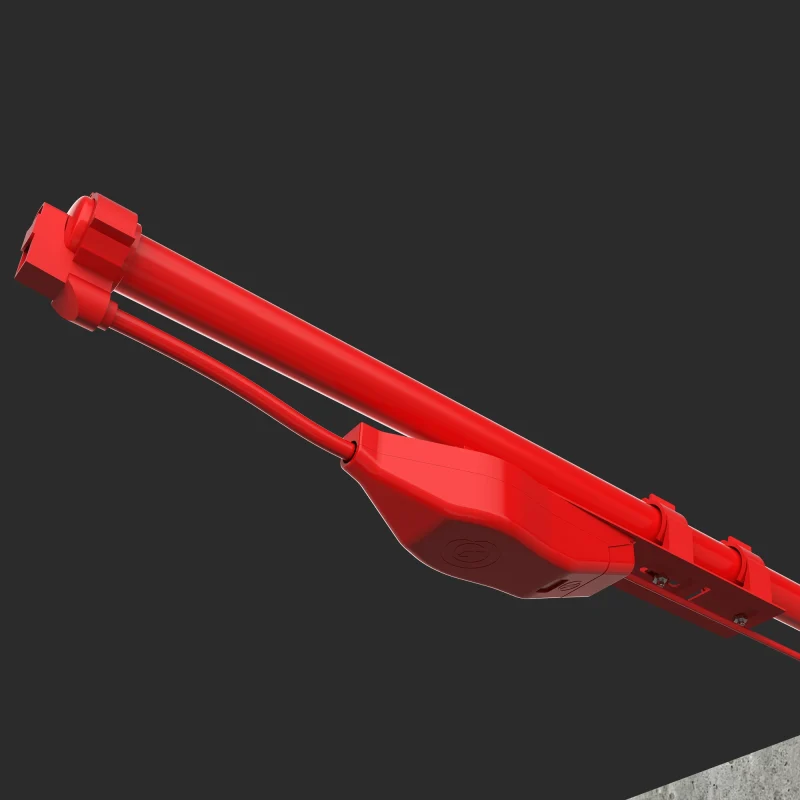

The Scorpion detector testing solution enables simple testing of ASD systems installed in hard-to-access locations.

The Scorpion system ensures compliance with stringent fire safety regulations and standards. It excels in accurately recording transport times for smoke particles, providing a precise assessment of system responses.

Its ability to mount in inaccessible areas simplifies comprehensive testing, even in hard-to-reach places. Overall, Scorpion Detector Test Equipment minimises downtime and operational disruptions, enhancing overall fire safety.

How it Works

Scorpion is installed permanently on the aspirating pipe, either at a floor level test point or at the end of the pipe run, and wired back to a conveniently mounted access point which can be used to initiate testing. This makes testing a hard-to-access ASD pipe quick and easy.

Demonstration

Why Choose Eurofyre?

- Complete System Supplier

- Eurofyre is a complete system supplier and has been a major Xtralis technical wholesaler since 2007. This means we can offer expert advice and supply all aspects of fire detection including aspirating smoke detection systems, conventional and addressable fire alarm control panels and linear heat detection.

- Demonstration and Training

- We have a sophisticated training facility where we offer demonstrations and expert training on a range of systems, including Scorpion Detector Test Equipment.

- After-Sales Support

- Eurofyre prides itself on providing after-sales care and support that is second to none. We offer both on-site and telephone assistance to help you ensure that your system is fully operational and working at its best.

For more information about Scorpion Detector Test Equipment or FAAST FLEX, or to discuss any of the other products that Eurofyre has to offer, please feel free to get in touch either by phone on +44 (0) 1329 835 024, by email to [email protected] or via the online enquiry form situated on our contact page.

Don’t forget you can follow us on LinkedIn, Twitter and Facebook or sign up to our newsletter (in the footer below) to receive all the latest information from Eurofyre.