Lifts, or elevators, are used to transport people or goods to different floors within a building. Usually, lifts are totally enclosed in lift shafts that rise vertically through a building. Lift shafts often terminate above roof level and can extend below ground if they are required to serve basement levels. These days, lift shafts are found in most multi-storey commercial and public buildings, such as offices, factories, car parks, shopping malls and high-rise flats.

Lift shafts serve various different functions including providing clear, unimpeded travel between floors, a degree of noise separation from the lift operating mechanisms and part of the structural core that stabilises buildings.

In the past, there have been a number of fire safety hazards associated with lift shafts:

- They can act as vertical channels for the spread of heat, smoke and toxic gases to other floors.

- Transient pressures inside the lift shaft caused by lift-cart movement (the piston effect) can allow smoke to infiltrate the shaft and spread to other parts of the building.

- They can entrap occupants and become a safety risk in the event of a fire.

However, thanks to the introduction of fire safety requirements and innovative fire detection technology, lift shafts also play a vital role in fire safety, offering two primary functions:

- Evacuation

Although some older buildings require lifts to be shut down in the event of a fire, lifts in most modern buildings can be integral to their evacuation plan and assist in getting occupants to safety. - Fire Fighter Access

Modern lifts often employ a fire service mode, which allows firefighters to use the lift safely to transport equipment and respond more quickly to fires.

In line with fire safety requirements, fast and reliable smoke detection equipment that can actuate smoke relief equipment is essential.

What are the Challenges?

When designing a reliable fire detection solution, lift shafts present a more challenging environment than most working environments. These challenges include:

- Contamination

- Higher levels of dust and other contaminants exist in lift shafts that can affect the reliable operation of detection equipment.

- Maintenance

- Access for maintenance of fire detection equipment is severely restricted in lift shafts and may require the entire system to be shut down for testing and repairs.

- Airflow

- Airflows created by the piston effect, stack effect (caused by a temperature differential between the inside and outside of the building) and the wind effect (where the pressure from the wind can cause a flow of air into the lift shaft) can increase smoke dispersion and dilution.

Handpicked Products for a Lift Shaft

Aspirating Smoke Detection provides an ideal solution when it comes to protecting lift shafts from fire. By using powerful aspirators to draw samples of air from the protected areas into a detection chamber, they can provide fast and reliable detection even in areas with high or erratic airflows.

Aspirating smoke detectors use sophisticated detection technology to differentiate between dust and smoke, and filters can be installed to remove contaminants before the sample air enters the detection chamber; this makes aspirating smoke detection almost totally impervious to dust and other contaminants.

The detectors themselves can be installed in a separate location and use a network of sampling pipes to reach the protected area. This means that they are completely accessible for testing, maintenance and repair.

In particular, the following components can make up a fast and reliable fire detection solution for lift shaft applications:

Aspirating Smoke Detector and Power Supply

ICAM IAS Aspirating Smoke Detector

ICAM IAS aspirating smoke detectors are well suited to a range of applications. They provide fast and reliable warning of fire and can be integrated with any fire alarm control panel. This detector combines standard field-serviceable detectors with a standalone air sampling solution, is cost-effective and is simple to install.

ProFyre P2 Power Supply Unit

ProFyre power supplies use state-of-the-art switch-mode power technology to deliver a continuous and reliable source of 24V DC power to meet the technical and legislative requirements of the professional fire detection and alarm industry/installer. LED indicators provide visual status of output voltage, output current, charge type and battery state.

ASD Pipe & Fittings

VESDA Red ABS 25mm Pipe

Our 25mm red ABS pipe is designed specifically for the aspirating smoke detection industry.

VESDA Red ABS 25mm Socket

Sockets are used to connect 2 lengths of pipe and are fixed using ABS solvent cement.

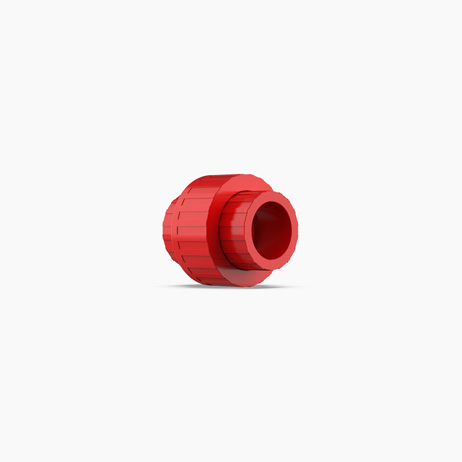

VESDA Red ABS 25mm Removable Union

The removable union is used to break sections of pipe for maintenance purposes.

VESDA Red ABS 25mm 90° Sweeping Bend

The 90° sweeping bends are used to divert pipework around obstructions and reduce air loss.

VESDA Red ABS 25mm Air Sampling Test Point

Air sampling test points allow for functional smoke testing of aspirating smoke detection systems and are typically located at the end of a sampling pipe network.

VESDA Red ABS 25mm x 3/4″ Pipe Clip

This pipe clip has been designed to secure air-sampling pipe using a quick clamp action without the need for additional fixings. Additional fixing nuts and side rod connectors complement the pipe clip for greater installation flexibility.

In-line Filter

VESDA In-line Filter

VESDA in-line filters provide a simple and cost-effective solution for addressing a variety of harsh environments with high levels of airborne contaminants. They improve detector longevity, reduce maintenance frequency and provide superior performance compared to other in-line filtration solutions.

Why Choose Eurofyre?

- Complete System Supplier

- Eurofyre manufactures and supplies all aspects of fire detection including aspirating smoke detection and its associated products and can provide expert advice and consultation.

- Demonstration and Training

- We offer demonstrations and expert training on a range of systems, including VESDA aspirating smoke detection systems, in our very own sophisticated training facility.

- After-Sales Support

- Eurofyre offers both on-site and telephone support to assist you in ensuring that your system is fully functional and operating at maximum efficiency. Our after-sales care and support are second to none.

For more information about VESDA aspirating smoke detection, or to discuss any of the other products that Eurofyre have to offer, please feel free to get in touch either by phone on +44 (0) 1329 835 024, by email to sales@eurofyre.co.uk or via the online enquiry form situated on our contact page.

Don’t forget you can follow us on LinkedIn, Twitter and Facebook or sign up to our newsletter (in the footer below) to receive all the latest information from Eurofyre.