Battery Energy Storage Systems (BESS) are advanced technology solutions that store electrical energy in rechargeable batteries for later use. They serve as a crucial component in the modern power grid, allowing for efficient management of electricity supply and demand.

BESS can store surplus electricity during times of low demand and release it during peak demand periods, enhancing grid stability and reliability. These systems play a vital role in integrating renewable energy sources, such as solar and wind, by storing excess energy for use when generation is low.

BESS can also provide backup power during outages and helps optimise the overall efficiency of energy distribution systems. When the main power source fails, the BESS quickly kicks in, supplying electricity to critical loads, such as hospitals, data centres, or residential areas, to ensure uninterrupted power supply.

What are the Risks?

There are a number of fire risks associated with BESS. These include:

- Thermal runaway

- Thermal runaway occurs when a battery cell or module overheats and reaches a point of uncontrollable thermal reaction, leading to a rapid increase in temperature and potentially causing a fire.

- Internal short circuits

- Internal short circuits within battery cells or modules can generate excessive heat and trigger a fire. These short circuits can be caused by manufacturing defects, mechanical damage or electrolyte leakage.

- External fire sources

- BESS installations are susceptible to external fire sources, such as nearby vegetation fires, electrical faults or adjacent building fires. If not properly protected, these external fires can spread to the BESS and ignite the battery cells.

- Electrical faults

- Faults in the electrical system, such as faulty wiring, connectors or monitoring equipment, can lead to electrical arcing or sparking, which can ignite flammable materials in the vicinity of the BESS.

- Improper installation or maintenance

- Poor installation practices or inadequate maintenance can increase the risk of fire in a BESS. Incorrect electrical connections, insufficient cooling systems, inadequate fire suppression measures or lack of regular inspections can all contribute to fire hazards.

What are the Challenges?

Designing a fire detection system for Battery Energy Storage Systems (BESS) comes with various challenges. These include:

- Early Detection

- BESS installations often have multiple modules or containers, making it challenging to detect localised fires in a timely manner.

- False Alarms

- Distinguishing between normal operation and actual fire events can be difficult. Battery systems generate heat during regular operation, and false alarms may disrupt the system’s functionality.

- Optimal Sensor Placement

- Determining the optimal locations for fire sensors within the BESS infrastructure can be a challenge. Factors such as temperature gradients, airflow patterns and potential fire pathways need to be considered during sensor placement.

- Compatibility with Battery Chemistry

- Different battery chemistries have distinct fire signatures, thermal behaviour, and outgassing characteristics. Designing a fire detection system that is compatible with various battery chemistries used in BESS installations poses a challenge to ensure accurate and reliable fire detection across different battery types.

- Contaminants

- BESS facilities can contain high-levels of dust and dirt which can become airborne and interfere with the detection of smoke particles.

Linear Heat Detection

Linear heat detection uses a heat-sensitive cable to detect temperature changes along its length. The cable is installed in proximity to the area being monitored, such as within enclosures or near critical components.

When used in BESS, linear heat detection can assist in early detection by sensing temperature increases. If the temperature exceeds a predetermined threshold, the cable triggers an alarm, alerting operators to potential overheating and fire risks. This allows for prompt intervention and mitigates the danger of Li-ion battery thermal runaway, helping prevent fires and ensuring the safety of Battery Energy Storage Systems.

Linear heat detection is unaffected by airborne fumes or other contaminants and can provide reliable detection of fire while minimising false alarms.

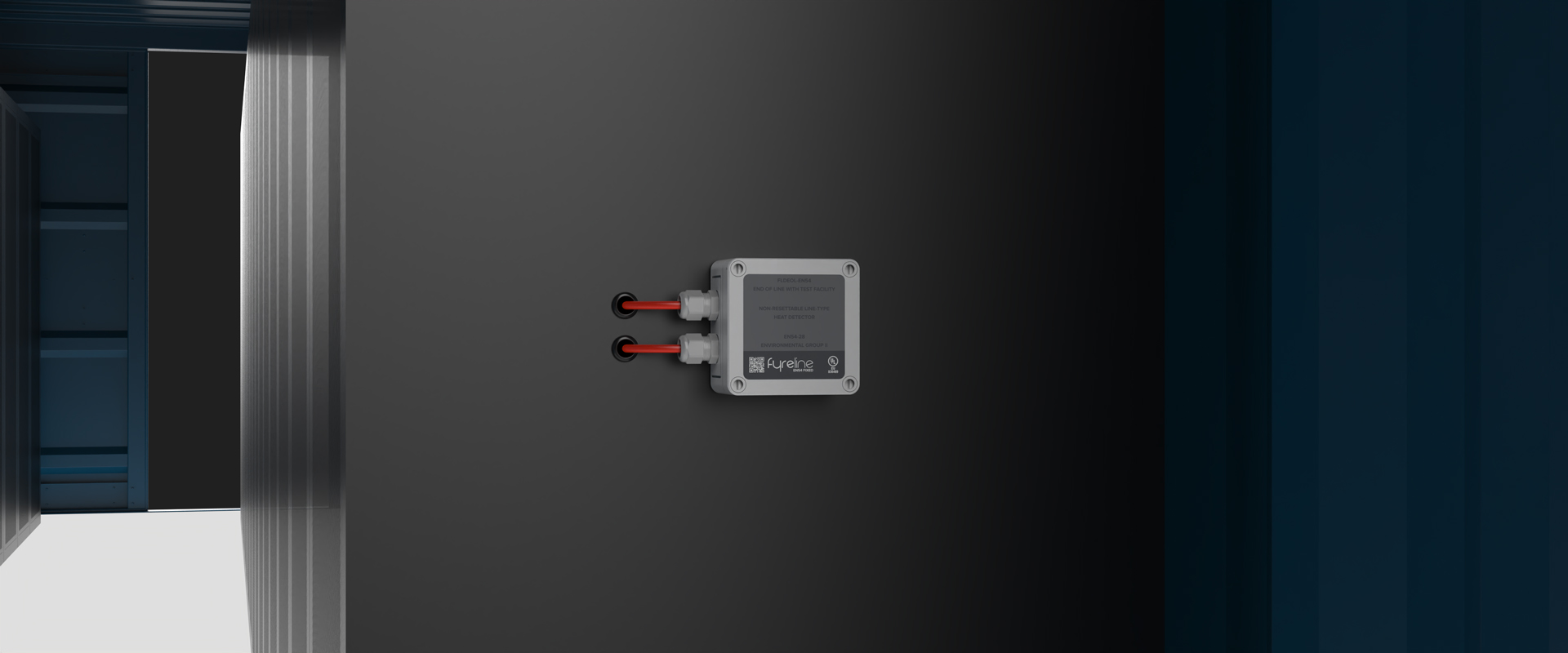

FyreLine EN54 Fixed Linear Heat Detection

FyreLine EN54 Fixed, developed by Eurofyre, is a linear heat detection system that conforms to the European standard BS EN 54-28:2016 for non-resettable line-type heat detectors.

It is specifically designed to be used in diverse applications, including Battery Energy Storage Systems. FyreLine EN54 Fixed supports two zones, each spanning up to 1000 metres, and can be seamlessly connected to either a conventional or addressable fire alarm control panel.

When a zone is activated, the control panel calculates the distance along the cable to pinpoint the alarm location, enabling quick identification of the threat so appropriate action can be taken.

Approvals

EN54 is a compulsory regulation that outlines the requirements for fire detection components and alarm systems and facilitates the free movement of construction products between European Union countries. It is mandatory for fire detection and alarm equipment to be certified under the EN54 standard by an authorised certification body, as stated by the Construction Products Regulation.

Please note: compliance with EN54-28 requires the use of the FyreLine EN54 Fixed Controller, FyreLine EN54 Fixed EOL and FyreLine EN54 Fixed LSZH LHD Cable as a complete system.

FyreLine EN54 Fixed Design Considerations

FyreLine EN54 Fixed systems comprise three key components: the FyreLine EN54 Fixed LSZH LHD Cable, FyreLine EN54 Fixed Controller, and FyreLine EN54 Fixed End Of Line (EOL).

Controller Placement

FyreLine EN54 controllers can be installed within the rack or in an external location. This provides easy access for maintenance and offers increased flexibility during the design stage.

Interlock/Coincidence Detection

FyreLine Fixed can be configured using interlock mode (also known as coincidence or double-knock) to prevent false alarms. In this mode, two fixed LHD cables are run side-by-side and an alarm is only activated on the fire alarm control panel when both cables trigger. This greatly reduces the risk of false alarm.

Linear Heat Detection Mounting Clips

There are a variety of mounting clips available for FyreLine EN54 Heat Sensing Cable. This includes the L-Clip that is most commonly used on flat mounting surfaces.

External Functional Alarm & Fault Testing

The FyreLine EN54 Fixed End Of Line has built-in switches to simulate fault or alarm conditions to allow the system to be fully tested in situ.

Why Choose Eurofyre?

- Complete System Supplier

- Eurofyre manufactures and supplies all aspects of fire detection, including linear heat detection and its associated products, and can provide expert advice and consultation.

- Demonstration and Training

- We offer demonstrations and expert training on a range of systems, including FyreLine linear heat detection systems, in our very own sophisticated training facility.

- After-Sales Support

- Eurofyre offers both on-site and telephone support to assist you in ensuring that your system is fully functional and operating at maximum efficiency. Our after-sales care and support are second to none.

For more information about EN54 Fixed Linear Heat Detection, or to discuss any of the other products that Eurofyre has to offer, please feel free to get in touch either by phone on +44 (0) 1329 835 024, by email to sales@eurofyre.co.uk or via the online enquiry form situated on our contact page.

Don’t forget you can follow us on LinkedIn, Twitter and Facebook or sign up to our newsletter (in the footer below) to receive all the latest information from Eurofyre.