Key Features

- Laser-based absolute smoke detection

- Very early warning of a potential fire incident

- Wide sensitivity range

- Dual stage dust filtration

- Programmable alarm thresholds

Overview

Introduction

Xtralis VESDA VLF Aspirating Smoke Detectors provide superior very early warning, air-sampling smoke detection for small, business-critical spaces such as switch rooms, server rooms and cabinets.

VESDA VLF aspirating smoke detectors continually draw air into their sampling chamber via discrete sampling holes in an aspirating pipe network. The air is filtered before entering the chamber, where light scattering technology detects even the smallest amounts of smoke. The detector communicates its status information on its intuitive ‘smoke dial’ display and via relays or optional interface cards.

Area Coverage

VESDA VLF is available in two versions: VESDA VLF-250 and VESDA VLF-500.

VESDA VLF-250 aspirating smoke detectors are designed to protect small, business-critical environments of less than 250 m2 (2,690 sq. ft.) while VESDA VLF-500 detectors are designed to protect small, business-critical environments less than 500 m2 (5,380 sq ft).

EN54-20 Aspirating Smoke Detection Sensitivity Classes

Fire detection classes A, B, and C classify fires based on materials and risks. Class A involves combustibles, B deals with flammable liquids, and C relates to electrical fires. VESDA VLF can provide class A, B or C fire detection with up to 12 sampling holes for VLF-250 or 30 sampling holes for VLF-500. Classification of any configuration is determined using ASPIRE2 Pipe Calculation Software.

| Class A | VLF-250: 12VLF-500: 30 |

| Class B | VLF-250: 12VLF-500: 30 |

| Class C | VLF-250: 12VLF-500: 30 |

Pipe Lengths

Vesda VLF-250 can support a single pipe run up to 25m, or 2 branches of 15m each. VLF-500 detectors can support a single pipe run of 50m, or 2 branches of 30m per branch.

| VESDA VLF-250, 1 Pipe, 1 Area Aspirating Smoke Detector | 1 x 25m2 x 15m per Branch |

| VESDA VLF-500, 1 Pipe, 1 Area Aspirating Smoke Detector | 1 x 50m2 x 30m per Branch |

Indication

VESDA’s unique Smoke Dial™ display gives the user an instant understanding of a smoke event. Smoke Dial™ uses a circular LED display and well-placed icons to provide a visual indication of smoke growth and alarm conditions, even from a distance.

In fault conditions, VESDA’s Smoke Dial™ display doubles up to provide VESDA’s innovative ‘fault finder’ feature – a smart diagnostic feature that provides instant and meaningful information of the detector’s status without the need for evaluation tools or additional programming. VESDA’s fault finding feature allows fire and maintenance staff to be better informed before arriving on site, saving time and reducing maintenance costs.

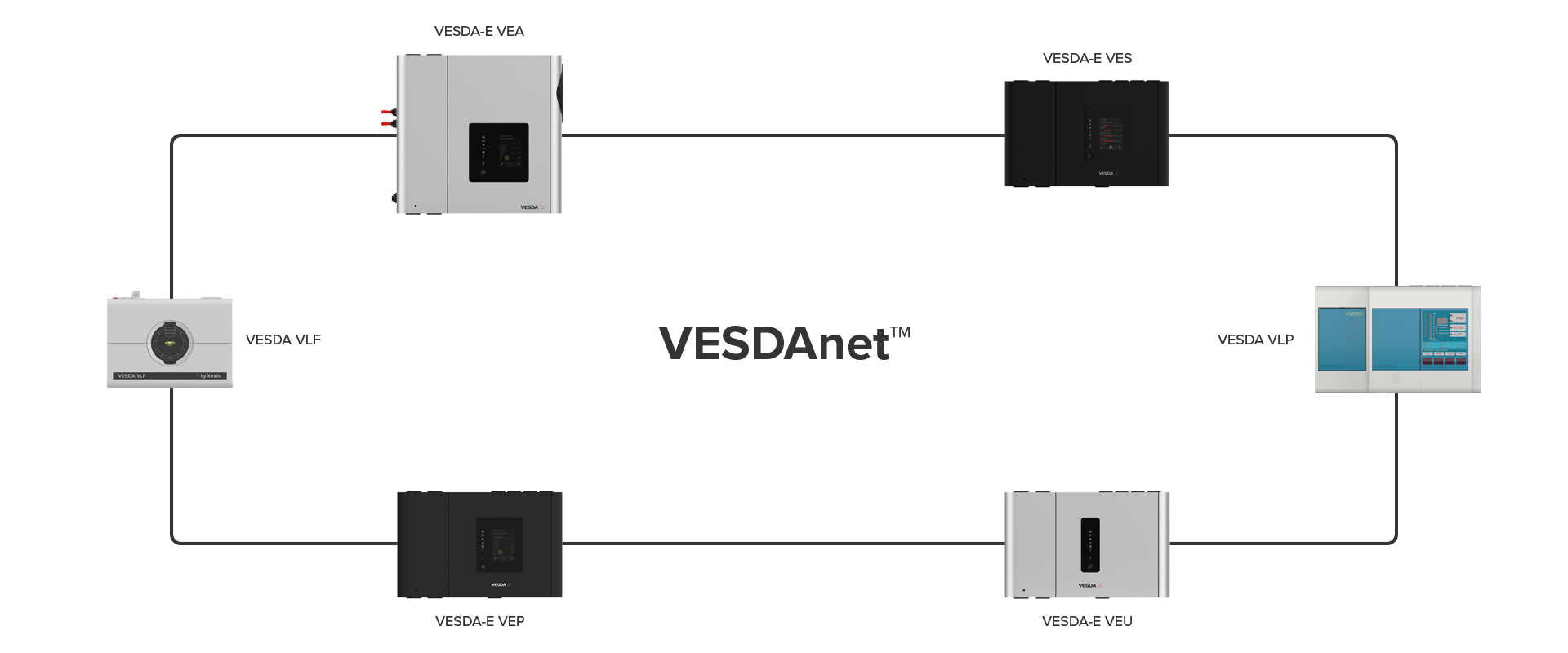

VESDAnet

VESDAnetTM enables primary reporting, centralised configuration, control maintenance and monitoring via a robust, bi-directional communication network that allows continued redundant operation even during single point wiring failures. VESDA VLF devices can be connected to VESDAnetTM via an optional VESDAnet Interface Card.

Turntable

Approvals

VESDA VLF Aspirating Smoke Detectors are fully approved by VdS for safe use and installation in any European Union country and bear the CE mark to show that they comply with all applicable Directives, including the CPR, EMC and the Low Voltage Directive (LVD).

These detectors are also certified to EN54-20:2006 + AC:2008 – Fire detection and fire alarm systems – Control and indicating equipment.

Tech Specs

| Input Power | Voltage: 24Vdc Nominal (18-30 Vdc) Current @ 24Vdc VLF-250: 220 mA nominal, 295 mA in alarm VLF-500: 410 mA nominal, 490 mA in alarm |

| Dimensions (W x H x D) | 256mm x 183mm x 92mm |

| Weight | Approximately 2kg (4.4 lbs) |

| IP Rating | IP30 |

| Mounting | Upright, inverted or horizontal |

| Operating Conditions | Ambient: 0°C to 39°C (32°F to 103°F) Product UL listed for use from 0°C to 38°C (32°F to 100°F) Tested to (EN54-20): -10°C to 55°C (14°F to 131°F) Sampled Air: -20°C to 60°C (-4°F to 140°F) Sampled Air temperature shall reach Ambient Detector temperature upon entry into Detector. Refer to Xtralis Design Guides & Application Notes for sampled air pre-conditioning. Humidity: 5% to 95% RH, non-condensing |

| Sampling Holes | VLF-250: Class A (12 holes / 0.12% obs/m) Class B (12 holes / 0.35% obs/m) Class C (12 holes / 0.80% obs/m) VLF-500: Class A (30 holes / 0.05% obs/m) Class B (30 holes / 0.15% obs/m) Class C (30 holes / 0.32% obs/m) |

| Sampling Network | Maximum pipe lengths VLF-250: 1 x 25m (80ft) (Max. 12 holes), 2 x 15m (50ft) per branch (Max. 6 holes per branch) VLF-500: 1 x 50m (150ft) (Max. 24 holes) 2 x 30m (90ft) per branch (Max. 12 holes per branch) Sampling Hole Options: Pre-Engineered Option or Maximum Pipe length in accordance with Pipe Modelling Design Tool (ASPIRE™) |

| Air Inlet Pipe | Accepts both metric and American standard pipe sizes Metric: 25mm (1.05 in.) American Pipe: IPS 21mm (¾ in.) |

| Area Coverage | VLF-250: Up to 250 m2 (2,690 sq. ft.) depending on local codes and standards VLF-500: Up to 500 m2 (5,380 sq. ft.) depending on local codes and standards |

| Relay Outputs | 3 changeover relays (Fire 1, Action, Fault), Contacts rated 2A @ 30Vdc (max). NO/NC Contacts |

| Cable Access | 3 x 25mm (11/16in.) cable entries (1 rear entry, 2 top entry) |

| Cable Termination | Screw Terminals 0.2-2.5 mm2 (30-12 AWG) |

| Interfaces | Shown in Terminal Block Connections diagram, to right, plus an RS232 Programming Port. General Purpose Input (GPI) interface offers: Reset, Disable, Standby, Alarm set 1, Alarm set 2 and External Input functions. |

| Alarm Threshold Setting Range | Alert, Action 0.025 – 2.00% obs/m (0.008 – 0.625% obs/ft) Fire 1, Fire 2 0.025 – 20.00% obs/m (0.008 – 6.25% obs/ft) Individual Alarm Delays 0 – 60 seconds Two Alarm Threshold Settings Either time or GPI based |

| Display | 4 Alarm State Indicators Smoke Level Indicator Reset, Disable and Test Controls Fault and Disabled Indicators Instant Fault Finder Smoke and Flow AutoLearn Controls |

| Event Log | Up to 18000 events, time and date stamped in separate, non-volatile, logs for: Smoke Level, Flow Level, Detector Status and Faults |

| AutoLearn Smoke & Flow | Automatically set acceptable alarm thresholds for both smoke and flow levels Minimum 15 minutes, maximum 15 days (default 14 days) During AutoLearn, thresholds are NOT changed from pre-set values |

Downloads

Datasheets

Manuals

Specifications

Approvals

- VESDA VLF LPCB Certificate

- VESDA VLF UL Certificate

- VESDA VLF FM Certificate

- VESDA VLF Declaration of Conformity

- VESDA VLF Declaration of Performance

Buy

Eurofyre is an authorised distributor of Honeywell and has been a major technical wholesaler of Xtralis products since 2007. We offer expert advice and supply all aspects of VESDA, FAAST and ICAM aspirating smoke detection systems including pipework calculations, demonstration/training and excellent after-sale support.

Contact us to receive competitive trade discounts or apply online for a credit account.