A solar farm is a large-scale installation of solar panels designed to harness sunlight and convert it into electricity. These sprawling arrays of photovoltaic panels are strategically placed in open areas to maximise exposure to sunlight.

Solar farms play a crucial role in generating clean, renewable energy, reducing greenhouse gas emissions, and combating climate change. They provide electricity to power homes, businesses, and even entire communities.

Solar farms are a sustainable and eco-friendly solution for meeting energy needs while minimising environmental impact, making them an essential part of the transition to a greener and more sustainable future.

Like most electrical installations, there is a high risk of fire. Therefore, solar farms should be protected by efficient and reliable fire detection systems.

What are the Fire Risks?

Solar farms come with some unique fire risks. These can include:

- Electrical faults

- Solar panels and their associated electrical systems can develop faults or malfunctions, leading to electrical arcing or short circuits, which can ignite fires.

- Weather-related events

- Extreme weather conditions such as lightning strikes, hailstorms, or strong winds can damage solar panels or their wiring, potentially causing electrical fires.

- Vegetation and debris

- Accumulation of dry vegetation, leaves, or debris on or around solar panels can provide fuel for fires, especially in hot and dry climates.

- Inverter failures

- Solar inverters, which convert DC power generated by panels into AC power for use, can overheat or malfunction, posing a fire risk.

- Poor maintenance

- Neglecting regular inspections and maintenance can lead to loose connections, damaged components, or deteriorating wiring, increasing the chances of fires.

Fire Detection Challenges

When it comes to designing a fire detection system for solar farms, there are a number of challenges to overcome:

- False alarms

- Solar panels can generate heat during normal operation, which may trigger false alarms. Distinguishing between harmless heat and a potential fire is a significant challenge.

- Environmental factors

- Solar farms are exposed to various environmental conditions like extreme temperatures, dust, and humidity, which can affect the reliability and accuracy of fire detection equipment over time.

- Accessibility and terrain

- Solar farms can cover large areas with varying terrains. Accessing all areas for installation, maintenance, and fire response can be difficult, especially in hilly or remote locations, which can impact the effectiveness of the fire detection system.

- Cost considerations

- Installing a comprehensive fire detection system can be expensive. Balancing the need for safety with budget constraints can be a significant challenge for solar farm operators.

- Integration with existing infrastructure

- Retrofitting fire detection systems into existing solar farms can be complex, requiring careful planning to avoid disruptions to ongoing operations and minimising the risk of false alarms.

Linear Heat Detection

Linear heat detection uses a heat sensing cable to detect changes in temperature. Linear heat detection can assist in early detection by sensing temperature increases along the length of the heat sensing cable. If the temperature exceeds a predetermined threshold, the cable triggers an alarm, alerting operators to potential overheating and fire risks. This allows for prompt investigation.

Linear heat detection is unaffected by environmental factors and can provide cost-effective and reliable fire detection for solar farm applications.

FyreLine Digital Linear Heat Detection

FyreLine Digital Linear Heat Detection Systems provide a cost-effective and reliable fixed temperature heat detection solution that is well suited to a wide range of applications, including solar farms. When an event is triggered, the distance along the cable to which the event has occurred is displayed on the control panel, enabling the user to easily locate the potential fire.

FyreLine Digital Heat Sensing Cable is made up of two tri-metallic conductors that are covered with heat sensitive polymers and twisted together before being encased in a protective outer sheath. Once the temperature sensitive polymer reaches its rated temperature it melts, causing the two conductors to come into contact. This sends a signal to the fire alarm control panel.

FyreLine Digital is cost-effective, low-maintenance and easy-to-install. Heat sensing cable can be provided with a nylon coating to protect it from UV rays and dust or debris does not affect its performance. Therefore, it is perfectly suited to solar farm installations.

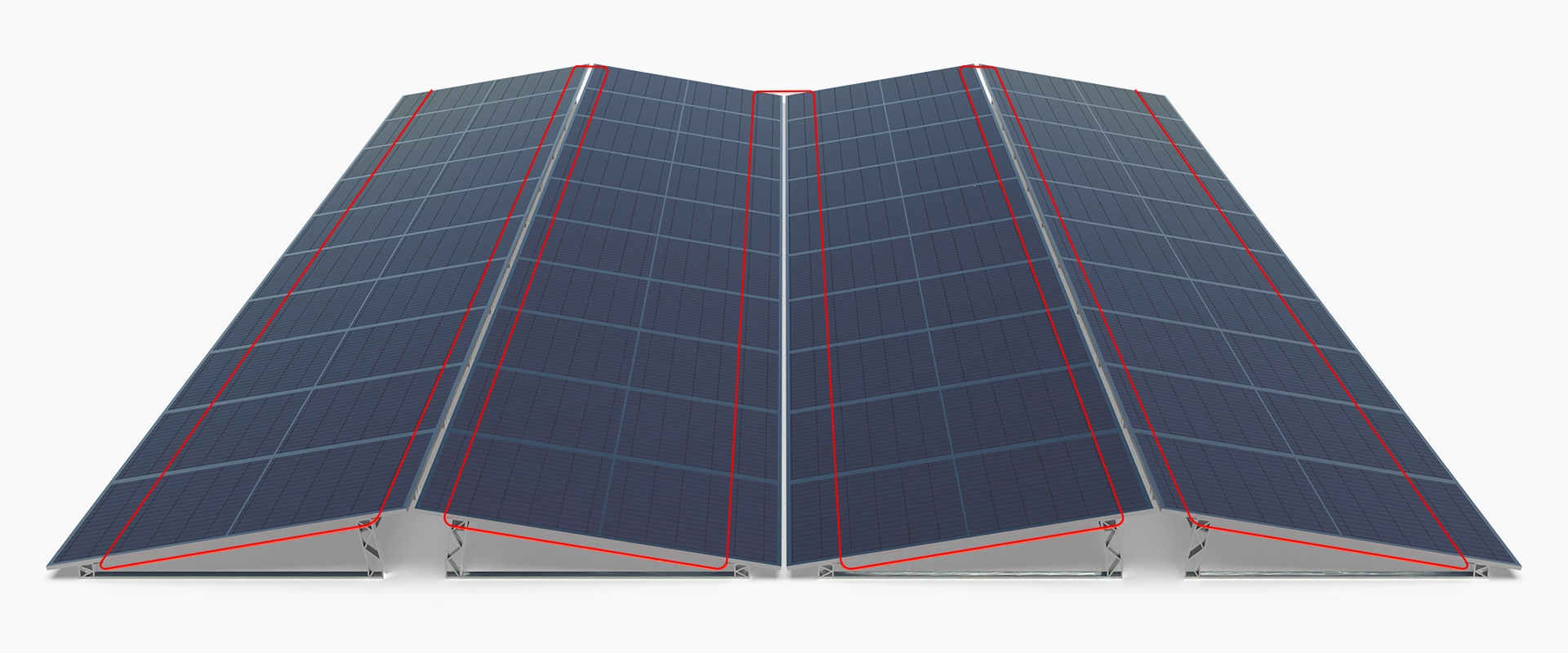

Typical Wiring Diagram

Linear Heat Sensing Cable can be installed below the solar panels, along the framework, to provide accurate detection. Controllers can be installed in an accessible, indoor location for easy access and maintenance.

Handpicked Products for Solar Farms

Typically, a FyreLine Digital Heat Detection System for a solar farm will be made up of the following components:

Linear Heat Detection Controller & Accessories

The FyreLine Digital Controller is a dual-zone module for monitoring up to two zones of LHD cable. If an overheat for fire event occurs, the unit displays the distance along the cable to the alarm trigger point. It has power, fault and alarm lights and volt-free outputs for fault and alarm. It can also be connected to an industrial process control system using the two-wire RS-485 Modbus RTU output.

FyreLine Digital EOL units with an incorporated test switch can monitor up to two LHD cables or zones and offer hassle-free functional testing of the system. They are used with interface modules to terminate LHD cable and, thanks to their carefully designed printed circuit board, incorporate a test switch that allows the user to simulate trouble, fault and alarm conditions.

Linear Heat Detection Cable

Nylon coated cable is the most suitable option for areas that are exposed to the elements, such as solar farms. It is black in colour and provides suitable UV protection when used in direct sunlight. Nylon is much tougher than PVC and therefore provides additional mechanical protection. A temperature rating of either 88℃ or 105℃ is most suitable for solar applications.

FyreLine Digital High Temperature LHD Cable is rated at 185℃ for high-temperature applications. It is manufactured from two different types of nylon, with the outer sheath being a chemical resistant material. Commonly used in high temperature, hazardous and safe areas where chemicals such as hydrocarbon fuel oils, diesel, kerosene etc. are present.

Mounting Clips & Accessories

The Fyreline J-Clip is a galvanised steel fixing designed to provide additional support for LHD cables. It has provision for a cable tie, ensuring it’s firmly secured to the J-Clip and can be used to support FyreLine Digital, EN54 Fixed and Analogue Linear Heat Detection Cable below or above the risk.

The L-Clip can be used to support FyreLine EN54 Fixed Linear Heat Detection Cable below or above the risk. They are most commonly used on flat mounting surfaces and are available in Zintec or stainless steel.

The P-Clip is suitable for indoor and outdoor use where mounting space is limited. Silicone sleeves are included in each pack to insulate and protect the LHD cable from abrasion, excessive pressure and any heat transfer from a metal mounting bracket to the cable, which may affect the operation of the cable.

FyreLine Stainless Steel Tie Wraps are used to safely secure the FyreLine linear heat cable to the chosen clips and brackets.

Why Choose Eurofyre?

- Complete System Supplier

- Eurofyre manufactures and supplies all aspects of fire detection including linear heat detection and its associated products and can provide expert advice and consultation.

- Demonstration and Training

- We offer demonstrations and expert training on a range of systems, including FyreLine linear heat detection systems, in our very own sophisticated training facility.

- After-Sales Support

- Eurofyre offers both on-site and telephone support to assist you in ensuring that your system is fully functional and operating at maximum efficiency. Our after-sales care and support are second to none.

For more information about linear heat detection, or to discuss any of the other products that Eurofyre have to offer, please feel free to get in touch either by phone on +44 (0) 1329 835 024, by email to [email protected] or via the online enquiry form situated on our contact page.

Don’t forget you can follow us on LinkedIn, X and Facebook or sign up to our newsletter (in the footer below) to receive all the latest information from Eurofyre.