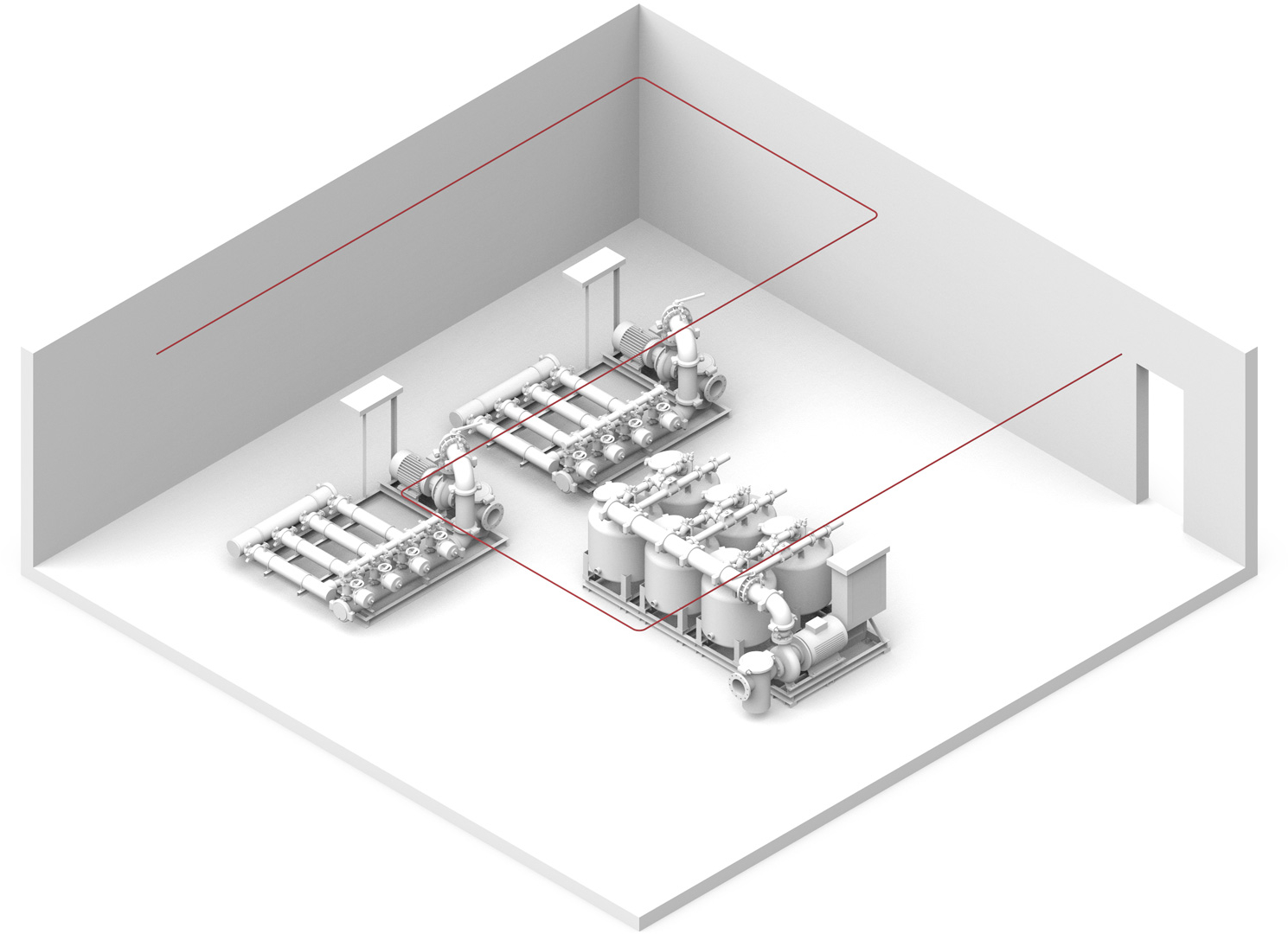

A boiler room, also known as a plant room or mechanical room, is a room or space in a building that is dedicated to mechanical equipment and its associated electrical equipment, separate from those intended for human occupancy or storage.

Boiler, or plant, rooms typically house essential mechanical equipment such as:

- Boilers

- Chillers

- Heat exchangers

- Water heaters and tanks

- Water pumps

- Main distribution piping and valves

- Sprinkler distribution piping and pumps

- Back-up generators

- Lift or elevator machinery

- Other heating ventilation and air-conditioning (HVAC) equipment

Boiler rooms are usually proportional to the size of the buildings and therefore, in larger buildings, can be a considerable size, often requiring multiple rooms and, in some cases, entire floors.

What are the Fire Risks Associated with Boiler, or Plant, Rooms?

There are a number of fire risks associated with this type of area. There is a huge amount of equipment that can be prone to overheating in a plant room – cable trays, boilers, gas pipes, standby generator sets, flammable liquids and materials are all typical in plant rooms, all leading to an increased risk of fire.

These rooms are essential to a building’s operation. If a fire is to break out in a building’s plant room, at the very least the building would not be able to function. Not only this but there is a high risk of the fire quickly spreading to other parts of the building. Therefore, a fire in a boiler room could lead to costly damage to equipment or property, cause serious downtime to a business and put lives in danger.

What are the Challenges?

Plant rooms are often very large areas containing lots of sizeable pieces of machinery and equipment. There is also often an incessant presence of smoke particles and atmospheric gases. These factors alone mean that traditional type detectors may be ineffective and produce recurring false alarms.

In some circumstances, a plant room’s environment may contain a mix of air and explosive gases, and therefore may be deemed to be a hazardous area. This makes maintenance difficult, and again, may render traditional type detectors ineffective.

What is the Solution?

FyreLine linear heat detection provides the ideal solution for protecting boiler rooms from fire. In fact, plant rooms are one of the biggest consumers of heat sensing cable. Linear heat detection can provide fast and reliable detection, in even the most difficult of environments. FyreLine linear heat detection systems are easy to maintain and can easily be replaced, removed or repositioned when necessary.

FyreLine linear heat detection is available in two types:

FyreLine Digital

FyreLine Digital provides fixed heat detection at a rated temperature of 68°C, 88°C, 105°C or 185°C. Once the cable reaches its rated temperature an alarm signal is sent to the fire alarm control panel to trigger the alarm.

FyreLine Analogue

FyreLine Analogue continually monitors for a change in temperature, only triggering an alarm once it reaches the temperature specified during the installation process. FyreLine analogue also provides the installer with the ability to define a pre-alarm temperature, allowing the end-user to investigate a potential fire before a full alarm is triggered.

Protective Coatings

Both versions of FyreLine heat detection systems are available with a range of coatings, making them suitable for use in a multitude of different environments. For example, a high temperature coating can be used in areas that are exposed to continually high temperatures, or nylon coating can be used in areas that are subject to high levels of UV or where hazardous hydrocarbons are present.

For more information about the FyreLine Linear Heat Detection System, or to discuss any of the other products that Eurofyre have to offer, please feel free to get in touch either by phone on +44 (0) 1329 835 024, by email to sales@eurofyre.co.uk or via the online enquiry form situated on our contact page.

Don’t forget you can follow us on LinkedIn, Twitter, Facebook and Google+ or sign up to our newsletter (in the footer below) to receive all the latest information from Eurofyre.