A refrigerated storage area, often referred to as a cold store or cool store, is a large refrigerated room or building that is designed for the storage of items in an environment below the outdoor temperature. Typically, refrigerated areas are used to store goods such as fruit, vegetables, seafood and meat. These areas are commonly located near shipping ports that are used for the import/export of produce.

Cold stores vary in size with some very small and others capable of storing thousands of tonnes of produce. One of the largest cold store facilities today boasts a massive 980,172,516 cubic feet (27,755,394 cubic meters) of cold storage place.

Like any area that is used for the storage of goods, it is necessary to have suitable and reliable fire detection installed to protect its stock and anyone entering the area from fire. These areas have a variety of fire risks and providing reliable detection can be challenging.

What are the Risks?

Like most environments, there are some unique fire risks associated with refrigerated areas:

- Ignition Hazards

Electrical faults from electrical and mechanical equipment such as conveyor and transport equipment can cause sparks and ignite nearby flammable materials. - Maintenance

Lighting or hotspots from maintenance operations can also cause flammable materials to catch alight. - Fuel Hazards

Highly combustible polystyrene, polyurethane foam, wooden pallets and plastic packaging can cause a fire to spread very quickly. The low humidity levels of cold stores can also cause a fire to burn stronger and quicker.

What are the Challenges?

Cold stores also present some unique challenges to fire detection:

- High-bay Storage Racking

High-bay storage racking can affect the airflow and impede the detection and response to a fire event. - Low Temperatures

Most detection types are not designed to operate in very low temperatures and would, therefore, be ineffective. - High Airflows

High airflows created by blast chiller units can also hamper the operation of conventional detectors.

What is the Solution

FyreLine Linear Heat Detection (LHD) can provide one of the most reliable and cost-effective fire detection solutions for refrigerated or cold store areas. FyreLine is suitable for use in areas with ambient temperatures as low as -50°C and is not affected by high airflow.

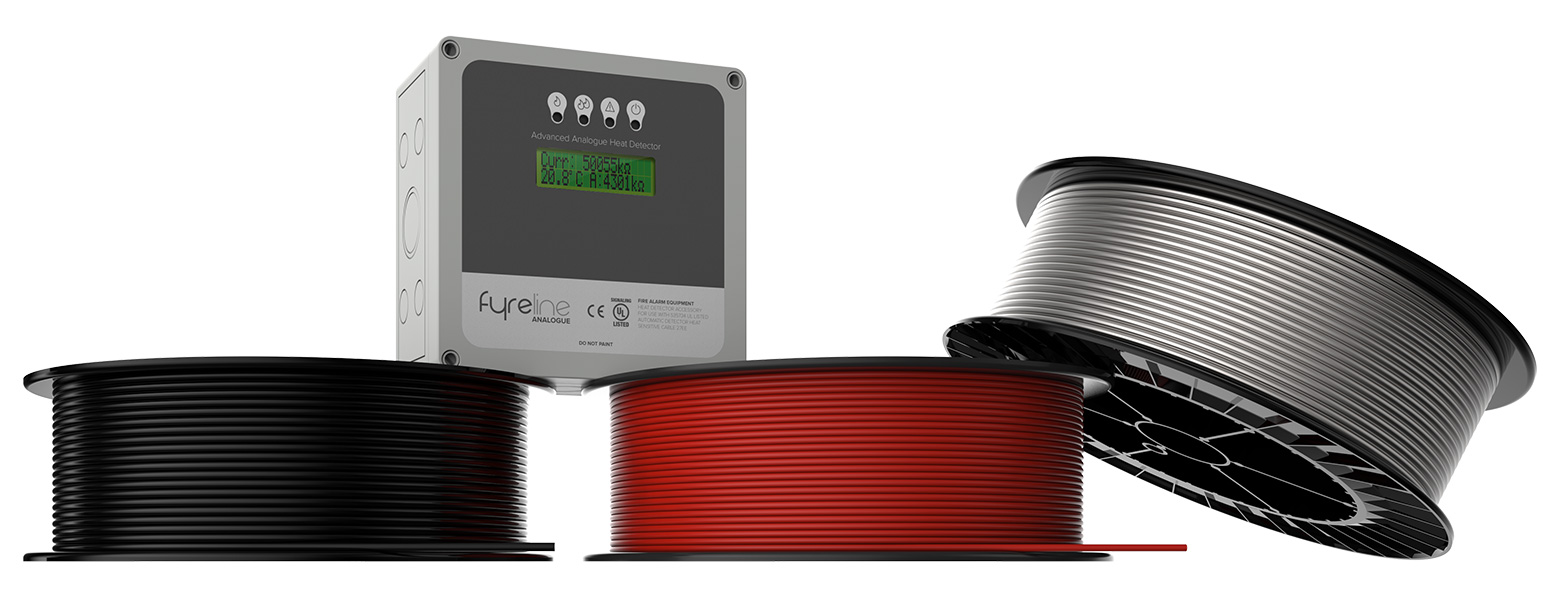

FyreLine cable can detect excess heat or fire anywhere along its length and can report an accurate location of the event. It is available with a range of coatings to protect the cable from even the harshest environments. In particular, a steel braided sheath is available to protect the cable from mechanical abrasion caused by machinery, loading and unloading or pinching and crushing.

Linear heat detection cable can be installed along any rack system and can be used in conjunction with any sprinkler system.

There are two types of FyreLine Linear Heat Detection available:

FyreLine Digital

FyreLine Digital offers fixed heat detection rated at a temperature of 68°C, 88°C, 105°C or 185°C. Once the cable reaches its rated temperature, a signal is reported to the fire alarm control panel. A digital interface module can also be used to calculate the distance along the cable to the alarm point.

FyreLine Analogue

FyreLine Analogue continually monitors for changes in temperature. Once the cables user-defined temperature is reached, a signal of fire is reported to the control panel. A pre-alarm temperature can also be defined, allowing time for potential fires to be investigated before the alarm is raised.

For more information about the FyreLine Linear Heat Detection system, or to discuss any of the other products that Eurofyre have to offer, please feel free to get in touch either by phone on +44 (0) 1329 835 024, by email to sales@eurofyre.co.uk or via the online enquiry form situated on our contact page.

Don’t forget you can follow us on LinkedIn, Twitter and Facebook or sign up to our newsletter (in the footer below) to receive all the latest information from Eurofyre.