Scaffolding is a temporary structure commonly used in construction and maintenance projects. It consists of various platforms, frames, and support elements that are assembled around a building or structure to provide access for workers and materials at elevated heights.

Scaffolding serves multiple purposes, including ensuring worker safety, facilitating construction or repairs, and offering a stable platform for tools and equipment. It also aids in reaching areas that are otherwise inaccessible, such as high walls or ceilings.

Scaffolding is an essential tool in the construction industry, enabling workers to carry out their tasks efficiently and securely while adhering to safety regulations.

Despite scaffolding mainly being temporary and used externally, there is still a high risk of fire and, therefore, suitable fire detection should be used to keep the building and anyone using the scaffolding safe from fire.

What are the Risks?

- Flammable materials

- Scaffolding often involves the use of wooden planks, boards, and cloth materials for safety netting. These materials are highly flammable and can ignite easily if exposed to sparks, open flames, or hot work processes.

- Electrical equipment

- Electrical tools and equipment used on or near scaffolding can be a source of fire risk, especially if they develop electrical faults or short circuits. Poorly maintained electrical connections can also lead to electrical fires.

- Welding and hot work

- Welding, cutting, or other hot work activities near scaffolding can generate sparks and radiant heat, which may ignite nearby materials or even the scaffolding structure itself if proper fire protection measures are not in place.

- Ignition sources

- Scaffolding sites may have various sources of ignition, such as portable heaters, open flames from torches or gas-powered tools, or smoking in restricted areas. Any of these sources can trigger fires if safety precautions are not followed.

- Poor housekeeping

- Accumulation of debris, rubbish, or flammable materials on scaffolding platforms can create an environment conducive to fires. Failure to maintain a clean and clutter-free workspace can increase the risk of ignition and fire spreading rapidly.

What are the Challenges?

- Environmental variability

- Scaffolding is exposed to outdoor conditions, which can be harsh and unpredictable. Weather elements like rain, wind, and temperature fluctuations can affect the reliability of fire detection equipment.

- False alarms

- Construction sites often produce dust, debris, and fumes that can trigger false alarms on traditional fire detection systems. Finding a balance between sensitivity to real fire hazards and immunity to common construction site nuisances is a significant challenge.

- Mobility and adaptability

- Scaffolding is temporary and frequently reconfigured as the construction progresses. The fire detection solution needs to be easily movable and adaptable to different scaffolding configurations without compromising its effectiveness.

- Maintenance

- Regular maintenance and testing of external fire alarm systems is crucial. Maintaining these systems, especially in hard-to-reach or exposed locations, can be costly and logistically challenging.

- Integration

- Construction sites are often large and spread out. Implementing a system that allows remote monitoring of fire detection alarms and integration with existing site safety protocols is crucial for timely responses to potential fires.

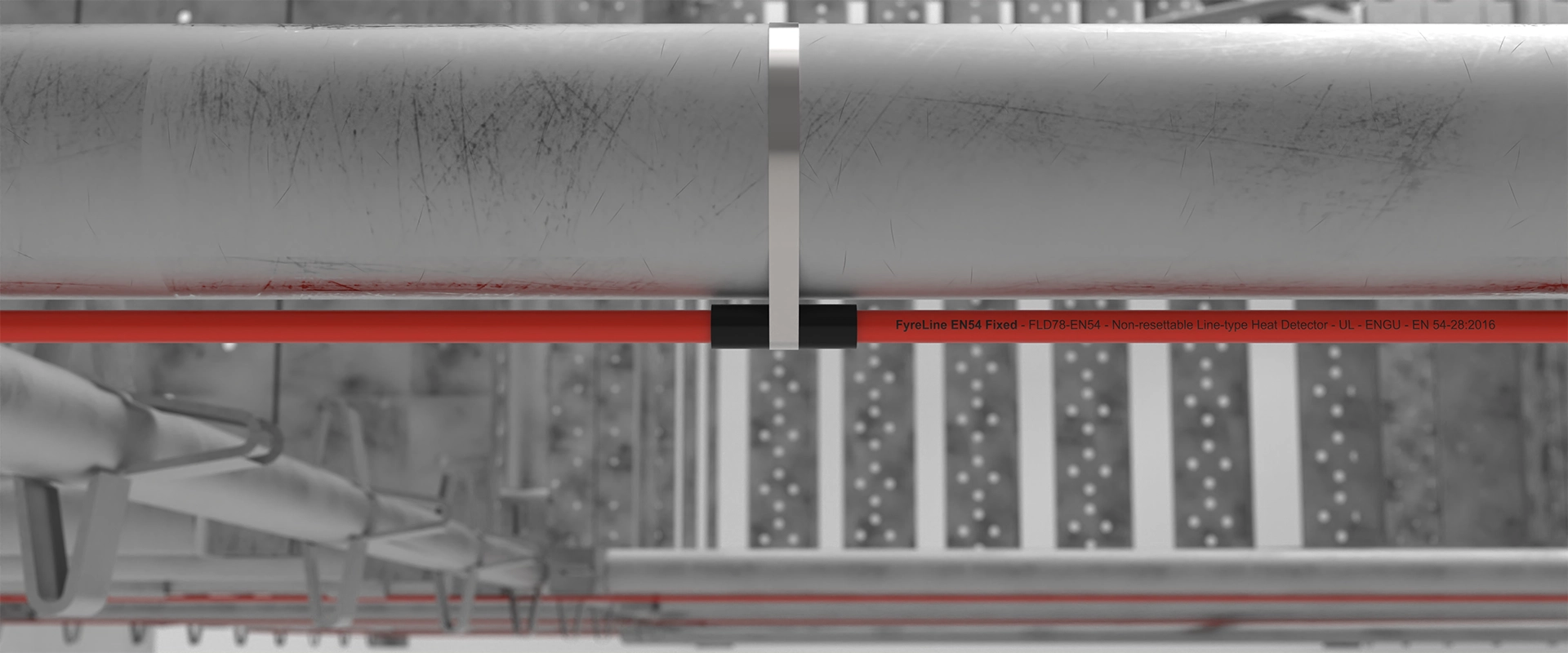

FyreLine EN54 Fixed Linear Heat Detection

FyreLine EN54 Fixed Linear Heat Detection can provide the ideal solution for protecting scaffolding from fire.

Developed by Eurofyre, FyreLine EN54 Fixed Linear Heat Detection conforms to the European standard BS EN 54-28:2016 for non-resettable line-type heat detectors.

FyreLine EN54 Fixed Linear Heat Detection uses heat sensing cable to detect increases in temperature and can provide an accurate location of an overheat event. Heat sensing cable can be installed along scaffolding runs to ensure optimum protection across all areas of the structure.

This powerful system provides very fast detection of fires, giving the user plenty of time to respond to a potential fire. It is easy-to-install and can easily be relocated or altered if the scaffolding is changed or removed.

FyreLine EN54 Fixed Linear Heat Detection is unaffected by external factors, dust or fumes. It is low-maintenance and can be easily integrated into a new or existing fire alarm system.

Approvals

EN54 outlines the requirements for fire detection components and alarm systems and facilitates the free movement of construction products between European Union countries. It is mandatory for fire detection and alarm equipment to be certified under the EN54 standard by an authorised certification body, as stated by the Construction Products Regulation.

Please note: in order to comply with EN54-28, FyreLine EN54 Fixed Controller, FyreLine EN54 Fixed EOL and FyreLine EN54 Fixed LSZH LHD Cable must all be used.

FyreLine EN54 Fixed Linear Heat Detection Design Considerations

FyreLine EN54 Fixed Linear Heat Detection Controller Placement

FyreLine EN54 Fixed Linear Heat Detection controllers can be installed in internal locations where they are protected from the elements, are secure and can be easily accessed for maintenance and testing.

FyreLine EN54 Fixed Linear Heat Detection Cable Placement

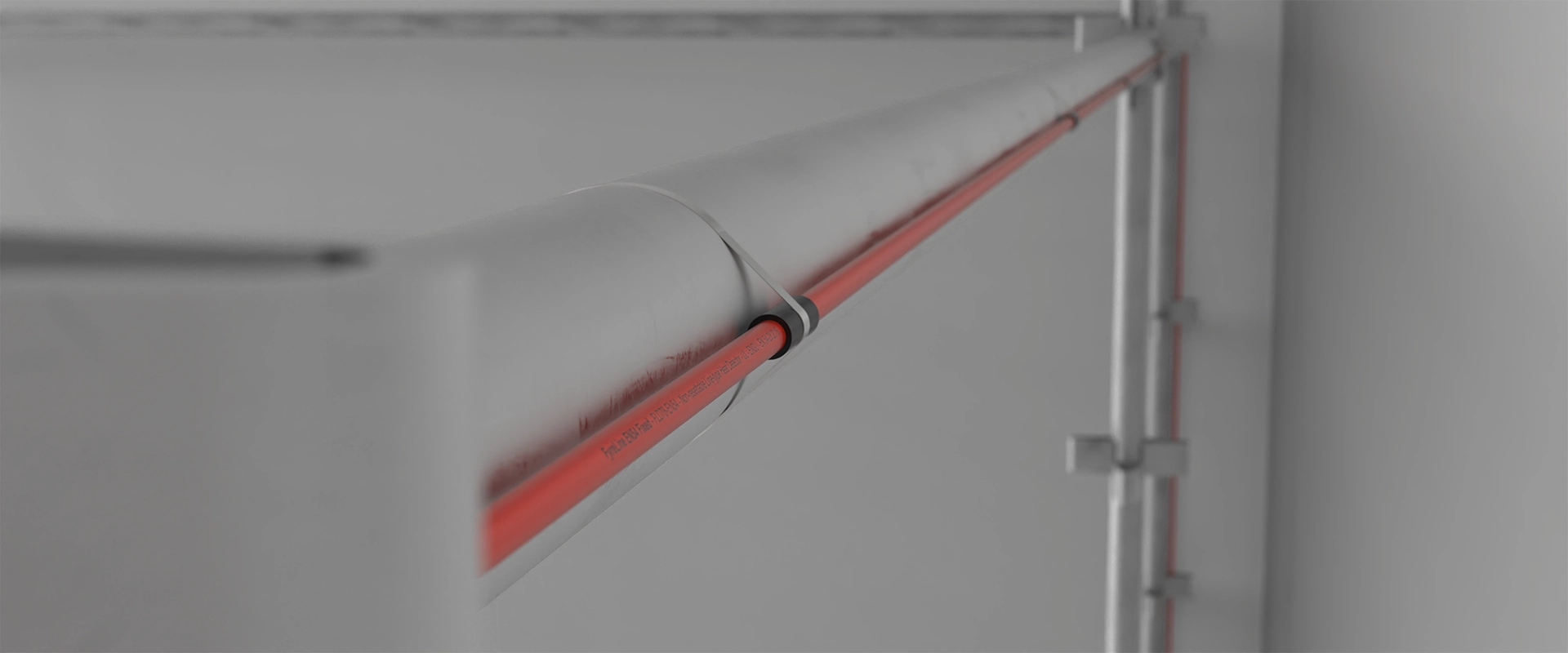

When using FyreLine EN54 Fixed Linear Heat Detection for scaffolding structures, heat sensing cable can be fixed directly to frames and guard rails.

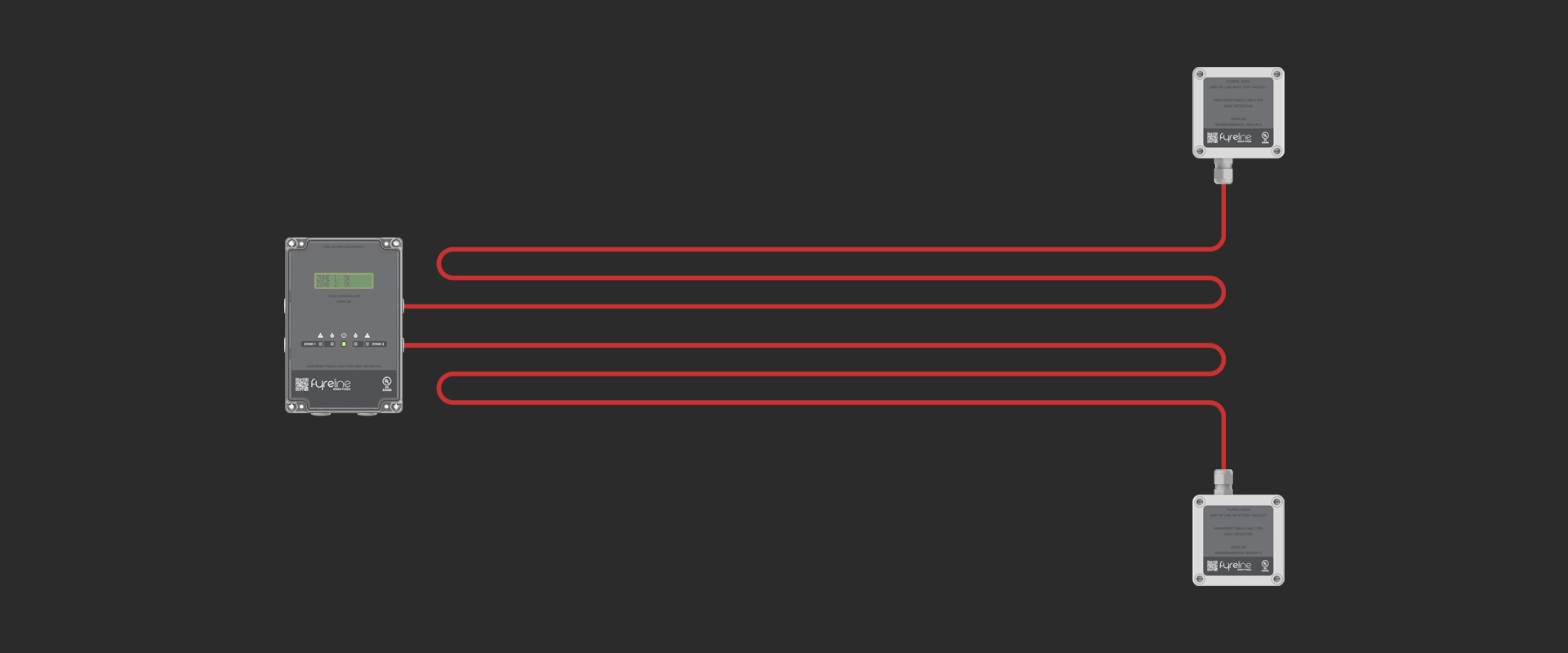

Independent & Interlock/Coincidence Detection

FyreLine EN54 Linear Heat Detection can be used in two different modes:

Interlock Mode

Also known as coincidence detection, interlock mode makes certain that an alarm is only triggered when an overheat condition has occurred. To achieve this, two Fixed LHD cables of the same temperature rating should be used for both zones. The alarm output is then only activated when both LHD cables trigger an alarm due to an overheat condition. This prevents alarms that might occur if a mechanical or other issue has caused only one of the sensing cables to trigger an alarm.

Independent Mode

In this mode each of the two zones operates independently. When a fault or overheat condition occurs on a Fixed LHD zone, the corresponding fault or alarm output is triggered. In this mode, each zone can contain either identical rated temperature LHD cables or two different rated temperature LHD cables.

FyreLine Linear Heat Detection Mounting Clips

When installing Linear Heat Detection for a scaffolding structure, the heat sensing cable can be fixed directly to frames and guard rails using metal cable ties with silicone sleeves to prevent damage at mounting points.

External Functional Alarm & Fault Testing

FyreLine EN54 Fixed End Of Lines are used to terminate each cable run and can be mounted directly to the scaffolding or inside the building it is surrounding. The FyreLine EOL has two built-in switches to simulate fault or alarm conditions to allow the system to be fully tested in situ.

Why Choose Eurofyre?

- Complete System Supplier

- Eurofyre manufactures and supplies all aspects of fire detection including linear heat detection and its associated products and can provide expert advice and consultation.

- Demonstration and Training

- We offer demonstrations and expert training on a range of systems, including FyreLine linear heat detection systems, in our very own sophisticated training facility.

- After-Sales Support

- Eurofyre offers both on-site and telephone support to assist you in ensuring that your system is fully functional and operating at maximum efficiency. Our after-sales care and support are second to none.

For more information about EN54 Fixed Linear Heat Detection, or to discuss any of the other products that Eurofyre has to offer, please feel free to get in touch either by phone on +44 (0) 1329 835 024, by email to [email protected] or via the online enquiry form situated on our contact page.

Don’t forget you can follow us on LinkedIn, X and Facebook or sign up to our newsletter (in the footer below) to receive all the latest information from Eurofyre.