A petrochemical plant is an industrial facility that processes petroleum or natural gas to produce various chemicals and products used in a wide range of goods. These plants are typically located near sources of crude oil or natural gas due to the raw materials needed for production. They are often located in strategic areas near major transportation hubs and industrial centres to facilitate efficient distribution of their products.

Petrochemical plants are used to produce a wide range of man-made materials such as plastics, fertilisers, pharmaceuticals, solvents, synthetic fibres, and more. The processes involved in producing these materials at petrochemical plants include refining crude oil or natural gas, separating various components through processes like distillation or cracking, and then chemically transforming these components into the required products through processes like polymerization or oxidation.

Overall, petrochemical plants play a crucial role in supplying the raw materials necessary for a variety of industries, including manufacturing, agriculture, healthcare, and construction. We use many products created by these materials in our daily lives, ranging from household items to advanced technological equipment.

What are the Risks?

Petrochemical plants are inherently associated with significant fire risks due to the nature of the substances they handle and the complex processes involved. The key fire risks commonly found in petrochemical plants are:

- Hydrocarbon Storage and Handling

- Petrochemical plants deal with large quantities of flammable hydrocarbons such as gasoline, diesel, and other volatile chemicals. Storage tanks, pipelines and handling equipment pose a significant fire risk due to the potential for leaks, spills or ignition during transfer operations.

- Process Equipment

- The various units within a petrochemical plant, including distillation columns, reactors, furnaces, and compressors, operate at high temperatures and pressures. Malfunctions, equipment failure or improper operation can lead to fires or explosions within these units.

- Chemical Reactions

- Petrochemical processes often involve complex chemical reactions. If these reactions are not properly controlled they can lead to runaway reactions, release of flammable gases or exothermic reactions resulting in fires or explosions.

- Ignition Sources

- Ignition sources such as electrical equipment, hot surfaces, welding, cutting or sparks from mechanical friction can ignite flammable vapours or gases present in the plant environment. Static electricity buildup is also a concern, particularly during handling and transfer of hydrocarbons.

- Human Error and Safety Procedures

- Human error, negligence or failure to adhere to safety protocols can significantly increase the risk of fires in petrochemical plants. Inadequate training, lack of proper maintenance or failure to follow established safety procedures can lead to incidents that result in fires or explosions.

Mitigating these fire risks requires robust safety measures, including regular equipment inspection and maintenance, implementation of strict operating procedures, comprehensive training programs for personnel, installation of fire detection and suppression systems, and adherence to industry regulations and standards.

What are the Challenges?

Effectively detecting fires in petrochemical plants presents several challenges due to the complex and hazardous nature of the environment. The main challenges include:

- Harsh Operating Conditions

- Petrochemical plants operate in harsh environments with high temperatures, corrosive chemicals and potentially explosive atmospheres. Standard fire detection systems may not withstand these conditions or provide accurate readings amidst the presence of various interfering factors.

- Diverse Range of Hazards

- Petrochemical plants handle a wide range of flammable substances, each with its own ignition characteristics and hazards. Traditional fire detection systems may not be capable of detecting all types of fires effectively, especially those involving rapidly evolving chemical reactions or low-energy smouldering fires.

- False Alarms

- The presence of dust, vapours and other airborne particles in petrochemical plants can trigger false alarms in conventional fire detection systems. Differentiating between genuine fire events and false alarms is crucial to prevent unnecessary plant shutdowns and ensure timely responses to real emergencies.

- Limited Visibility

- Petrochemical plants often have large and complex layouts with confined spaces, obstructed views and inaccessible areas. Achieving adequate coverage for fire detection throughout the facility can be challenging, especially in areas with limited visibility or where conventional detection methods are impractical.

- Maintenance and Reliability

- Conducting routine maintenance and testing procedures may be challenging due to operational constraints, safety regulations and the need to minimise downtime.

Addressing these challenges requires the implementation of advanced fire detection technologies; linear heat detection systems offer an effective solution for safeguarding petrochemical plants against the threat of fire due to their versatility, reliability and early detection capabilities.

These systems provide continuous coverage along extended lengths, ensuring comprehensive monitoring of large areas within the plant, including remote or challenging-to-access locations. They are designed to withstand harsh industrial environments characterised by high temperatures, humidity, dust and corrosive atmospheres, making them well-suited for use in petrochemical facilities.

FyreLine EN54 Fixed Linear Heat Detection

The FyreLine EN54 Fixed Linear Heat Detection system is a state-of-the-art linear heat detection solution designed to meet the stringent standards of the European fire safety industry. The FyreLine EN54 Fixed system offers advanced features and reliable performance for fire detection in various environments, including petrochemical plants, industrial facilities, warehouses, tunnels, and more.

The FyreLine EN54 Fixed system utilises linear heat detection technology to provide continuous monitoring along extended lengths. It detects changes in temperature along its length caused by fire, overheating equipment or other thermal anomalies, enabling early detection and rapid response to fire incidents.

Built to withstand harsh industrial environments, the system is rugged and durable, ensuring reliable performance even in the most demanding conditions. It is resistant to environmental factors such as vibration, moisture and electromagnetic interference, maintaining its effectiveness over time.

Approval

EN54 outlines the requirements for fire detection components and alarm systems and facilitates the free movement of construction products between European Union countries. It is mandatory for fire detection and alarm equipment to be certified under the EN54 standard by an authorised certification body, as stated by the Construction Products Regulation.

Please note: to comply with EN54-28, the FyreLine EN54 Fixed Controller, FyreLine FyreLine EN54 Fixed EOL and FyreLine EN54 Fixed LSZH LHD Cable must be used as a complete system.

FyreLine products are also approved by internationally recognised testing authorities, including the Underwriters Laboratories (UL). They are CE marked to show compliance with all the applicable directives, as well as UKCA marked to indicate conformity with the applicable requirements for sales in the United Kingdom.

FyreLine EN54 Fixed Linear Heat Detection Design Considerations

FyreLine EN54 Fixed Linear Heat Detection Controller Placement

FyreLine EN54 Fixed Linear Heat Detection controllers should be installed in safe locations indoors where they are secure, protected from the elements and can be easily accessed for maintenance and testing.

FyreLine EN54 Fixed Linear Heat Detection Cable Placement

In petrochemical industrial settings, heat sensing cable for the FyreLine can be fixed directly to gas pipes using the appropriate mounting clips.

Independent & Interlock/Coincidence Detection

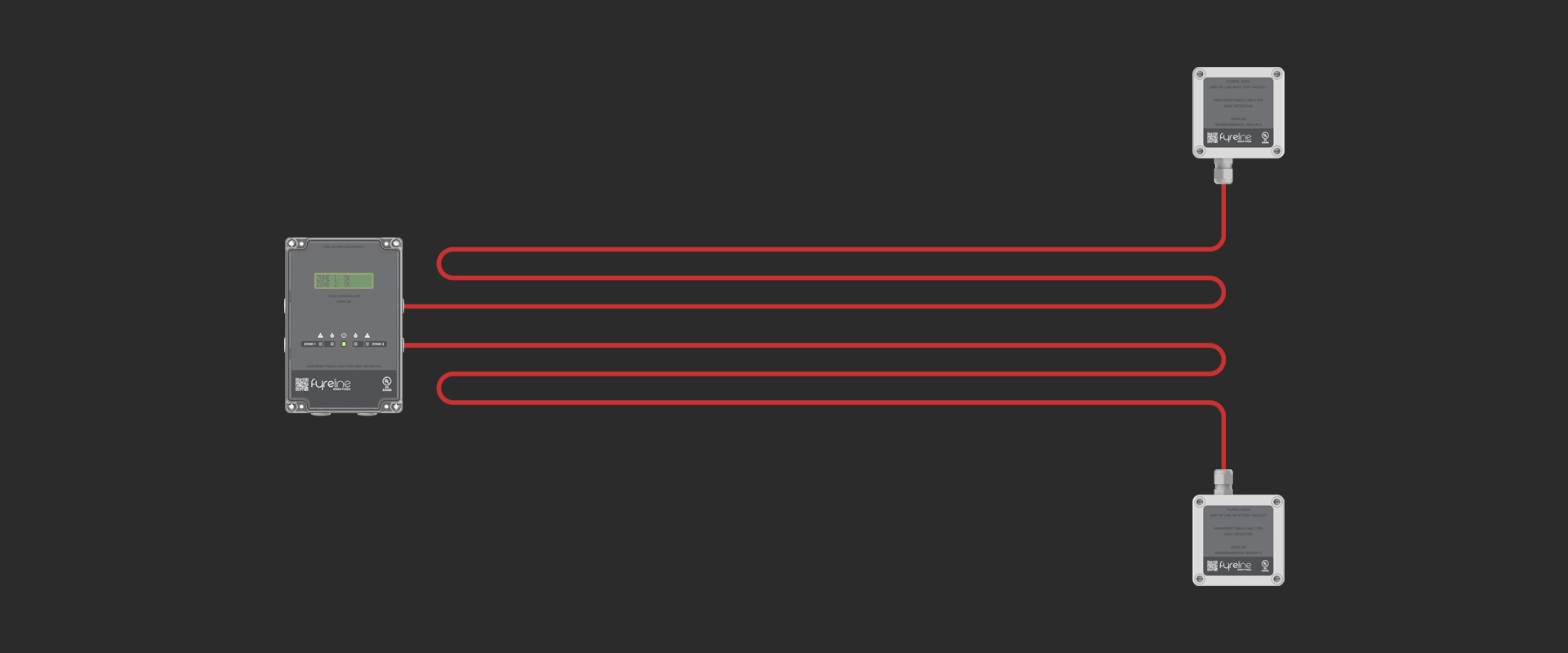

Each zone of the FyreLine EN54 controller can operate either independently of each other, where separate alarm and normally conducting fault outputs are available for each zone, or in Interlock Mode, otherwise known as coincidence detection.

Interlock Mode

Interlock Mode is ideal for applications which require a fail-safe; a guarantee that an alarm is only triggered when an overheat condition has been detected. The same rated temperature Fixed LHD cable should be used for both zones, run side-by-side, and an alarm is only activated on the fire alarm control panel when both cables trigger due to an overheat condition. If one Fixed LHD cable zone input registers an alarm but the second does not, the alarm output will not be activated.

Independent Mode

In Independent Mode, the FyreLine EN54 Fixed LHD system is used as a two-zone system, with separate cable runs. If an overheat condition occurs in either zone, an alarm will be triggered, with no fail-safe mechanism. In this mode, differently rated temperature LHD cables can be used in each zone to further enhance the flexibility of the system to fully protect the nuances of the environment.

FyreLine Linear Heat Detection Mounting Clips

The type of mounting clip used should be appropriate for the application at hand; the clips chosen should withstand a similar temperature and duration to that of the cable, while maintaining adequate support, ensuring that circuit integrity will not be reduced below that afforded by the cable used.

In petrochemical plants, stainless steel mounting accessories are suitable for indoor and outdoor use in environments where the clip may be exposed to harsh chemicals.

External Functional Alarm & Fault Testing

The FyreLine EN54 EOL is used to terminate the other end of the heat sensing cable. It is designed to terminate up to two zones of FyreLine EN54 Fixed Linear Heat Detection Cable. Housed in a secure, weatherproof enclosure, it has built-in switches that are used to simulate fault or alarm conditions to allow the system to be fully tested in situ.

Why Choose Eurofyre?

- Complete System Supplier

- Eurofyre manufactures and supplies all aspects of fire detection including linear heat detection and its associated products and can provide expert advice and consultation.

- Demonstration and Training

- We offer demonstrations and expert training on a range of systems, including FyreLine linear heat detection systems, in our very own sophisticated training facility.

- After-Sales Support

- Eurofyre offers both on-site and telephone support to assist you in ensuring that your system is fully functional and operating at maximum efficiency. Our after-sales care and support are second to none.

For more information about FyreLine EN54 Fixed Linear Heat Detection, or to discuss any of the other products that Eurofyre has to offer, please feel free to get in touch either by phone on +44 (0) 1329 835 024, by email to [email protected] or via the online enquiry form situated on our contact page.

Don’t forget you can follow us on LinkedIn, X and Facebook or sign up to our newsletter (in the footer below) to receive all the latest information from Eurofyre.