Warehouses are buildings that are used to store goods. Manufacturers, importers, exporters, wholesalers and more all use warehouses to keep products. They are usually very large, plain buildings in industrial parks on the outskirts of cities, towns and villages.

Goods stored in warehouses can include anything from raw materials, spare parts and components to packing materials and finished products. These goods are typically stored on pallets and loaded into pallet racks in the warehouse facility.

Warehouses usually have loading docks to unload goods from trucks and sometimes are designed for goods to be unloaded directly from railways, airports or sea ports. Cranes and forklifts are then used to move goods around the warehouse.

Warehouses often contain an abundance of valuable products and materials. They can operate twenty-four hours of every day and are always manned with large teams of personnel. Therefore, it is essential that suitable and reliable fire detection is in place.

What are the Risks?

There are a variety of fire risks within warehouses. Some of the most common include:

- Flammable Materials

- Flammable materials such as packaging, chemicals and other items stored in warehouses can cause fires to spread very quickly.

- Machinery

- Warehouses operate a wide variety of different machinery and electrical equipment. If this equipment is not maintained properly it can overheat, develop electrical faults or hotspots and set nearby materials alight.

- Incorrect Storage

- If certain items are not stored correctly they can cause fires to spread very quickly.

- Dust

- Dust and dirt is often in abundance in warehouse facilities. This can be extremely flammable and cause fires to spread very quickly.

- Poor Housekeeping

- If items such as general waste, public bins or packaging are not cleared away or stored correctly they can cause fire to spread more quickly. This can also block fire escapes and slow evacuation.

What are the Challenges?

There are also a number of challenges associated with providing fire detection for warehouses, these can include:

- High Ceilings

- High ceilings in warehouses can delay any smoke reaching ceiling-mounted detectors. They can also cause smoke stratification, preventing the smoke from reaching detectors altogether.

- Vast Open Spaces

- Large open spaces can create high and unpredictable airflows. This can cause smoke to behave erratically or become diluted and make it extremely difficult for traditional types of smoke detectors to identify.

- Contaminants

- Warehouses can contain high-levels of dust and dirt which can become airborne and interfere with the detection of smoke particles.

- Fumes

- Fumes from machinery such as forklifts and cranes can cause problems for some types of fire detection.

- Machinery and racking can also cause obstructions and interfere with the behaviour of smoke, making it difficult to detect.

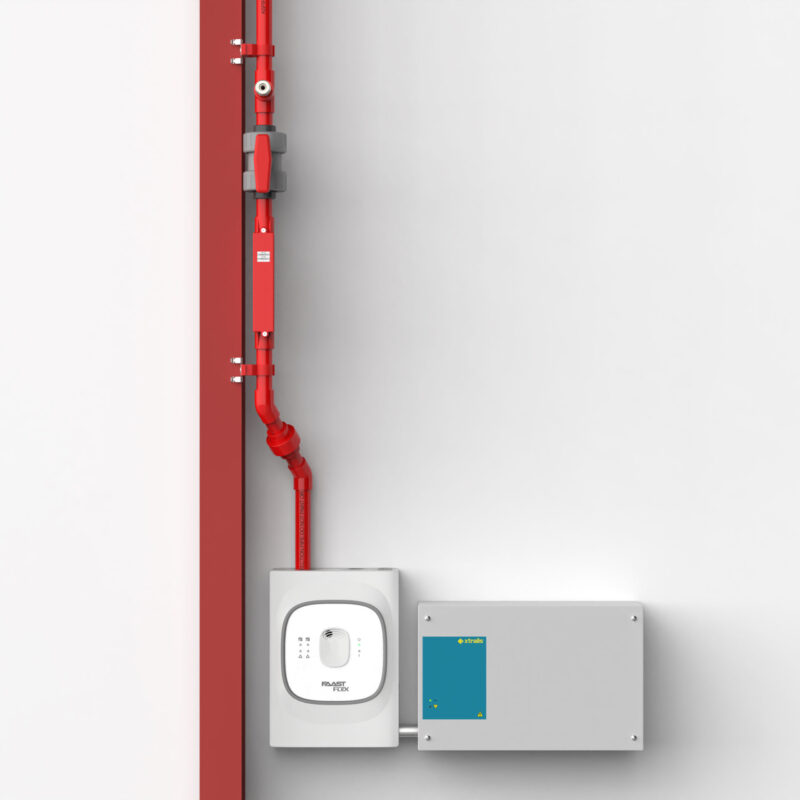

FAAST FLEX

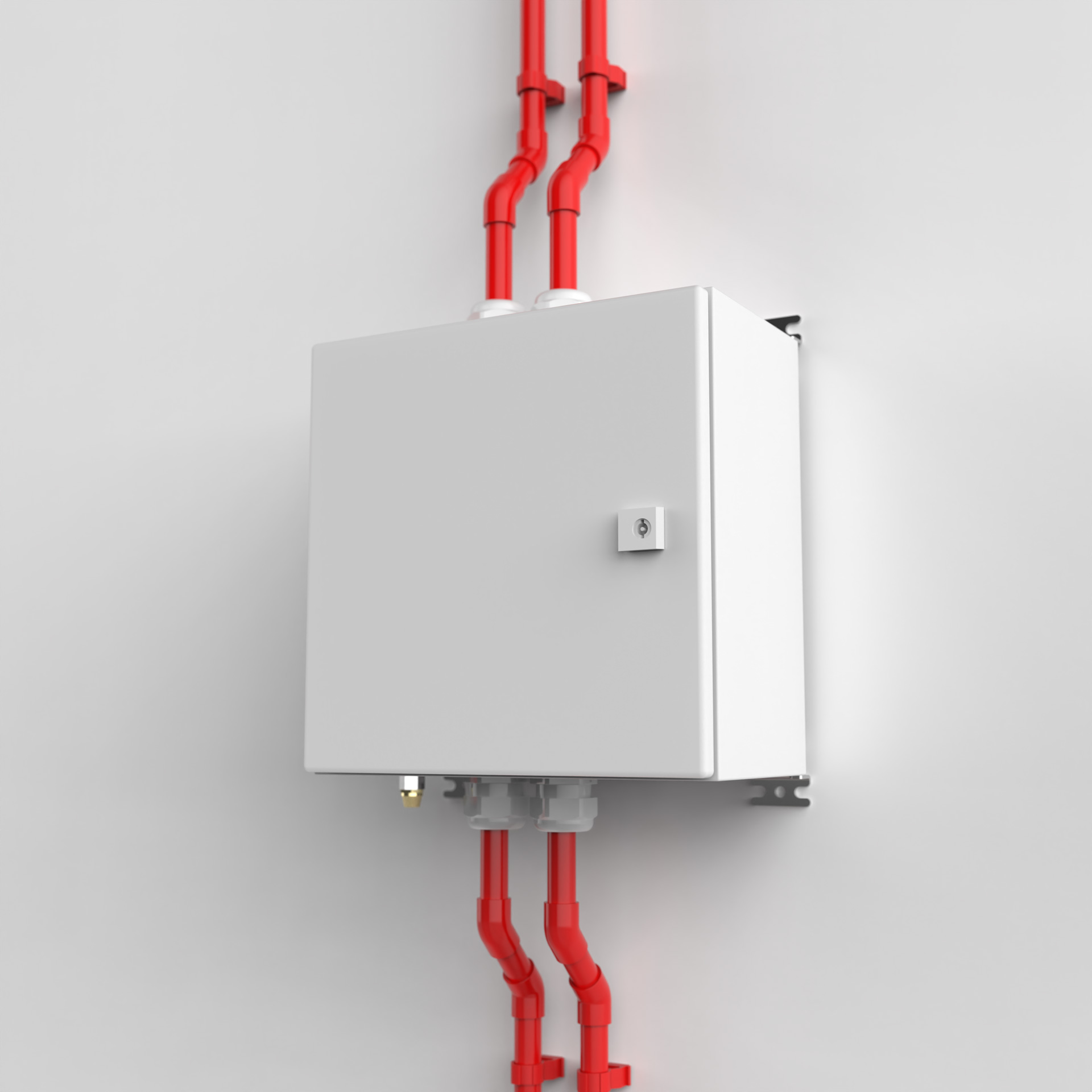

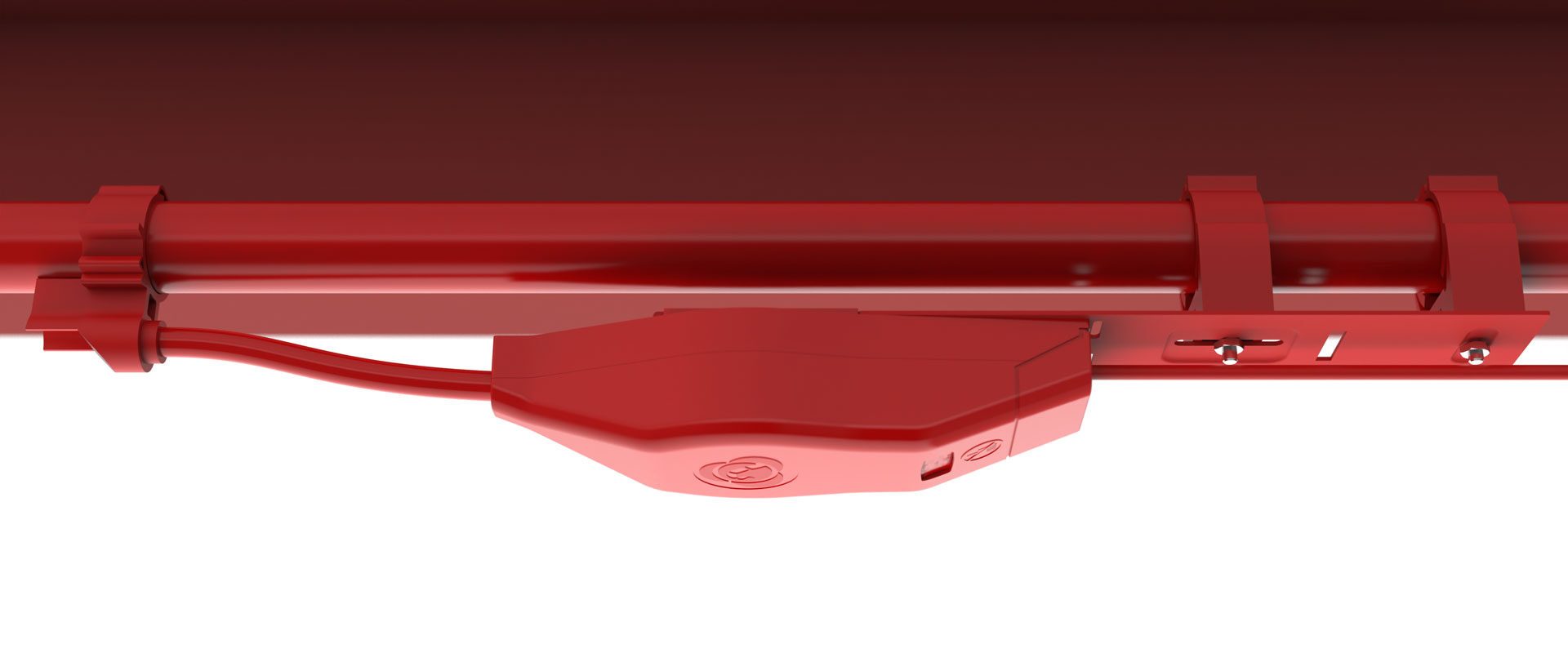

FAAST FLEX aspirating smoke detectors provide a highly-flexible and cost-effective aspirating smoke detection solution for a wide range of applications such as small to medium sized warehouses, cold storage facilities, lift shafts, ceiling voids, underfloor voids, transformer and electrical rooms and many more.

FAAST FLEX detectors are available as either a one-channel or two-channel detector and uses an advanced detection chamber to provide constant detection with minimal false alarms.

These detectors draw air through a network of sampling pipes using a speed adjustable aspirator. Air samples are filtered and passed into the detection chamber where they are analysed for the presence of smoke. Air is then exhausted from the FAAST FLEX and can be vented back into the protected zone. This means that FAAST FLEX detectors are unaffected by obstacles, high ceilings, unpredictable airflows or airborne contaminants.

Pre-engineered pipe network design, out-of-the-box operation and built-in configuration and control mechanisms make these detectors incredibly versatile and cost-effective.

Modular design and field-replaceable components make in-field servicing and maintenance easy.

FAAST FLEX Design Considerations

There are a number of design considerations when designing any aspirating smoke detection system for warehouses. This type of building is often constructed using beams and with apex roofs. Environmental conditions can cause the building to move. Obstacles and contamination must also be considered.

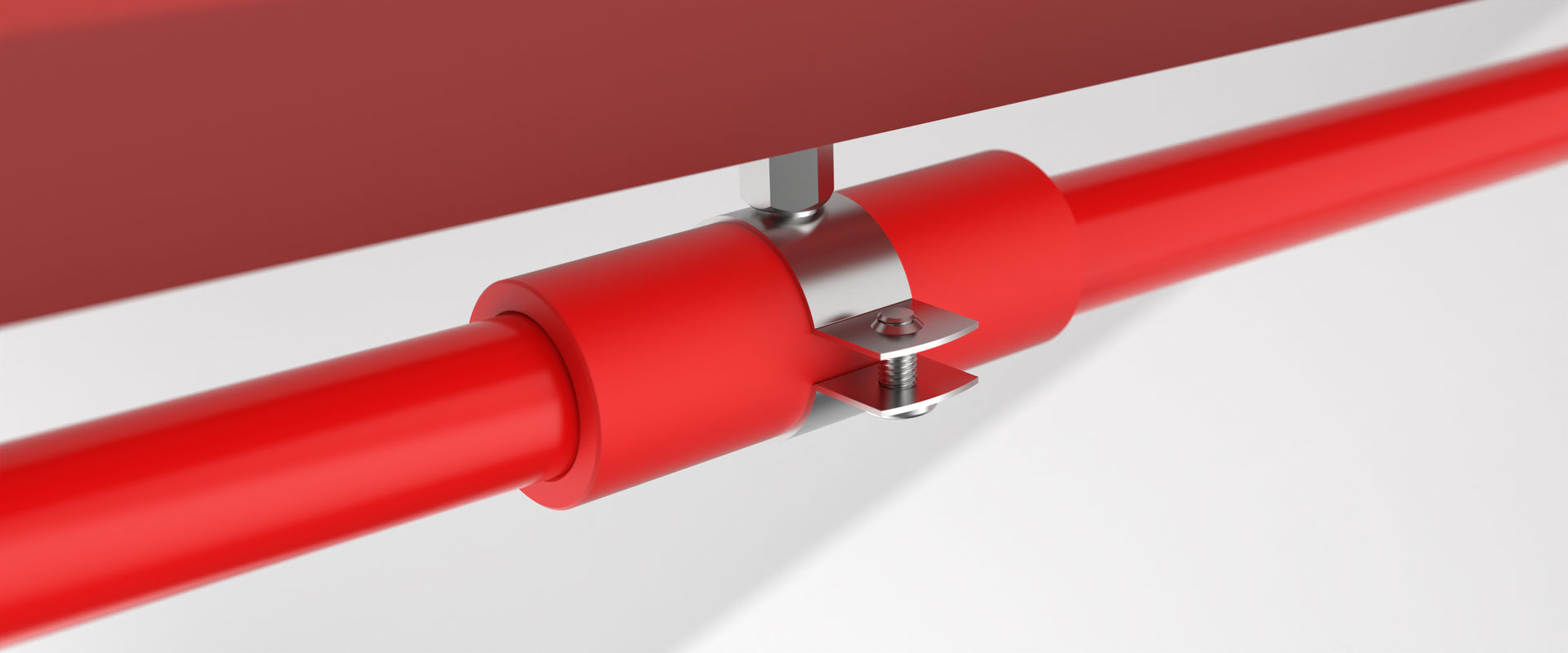

Sampling Pipe Fixing Clips

We have a variety of aspirating pipe clips available to make securing aspirating smoke detection pipe simple. Beam clips are also available for mounting pipework directly to steel beams.

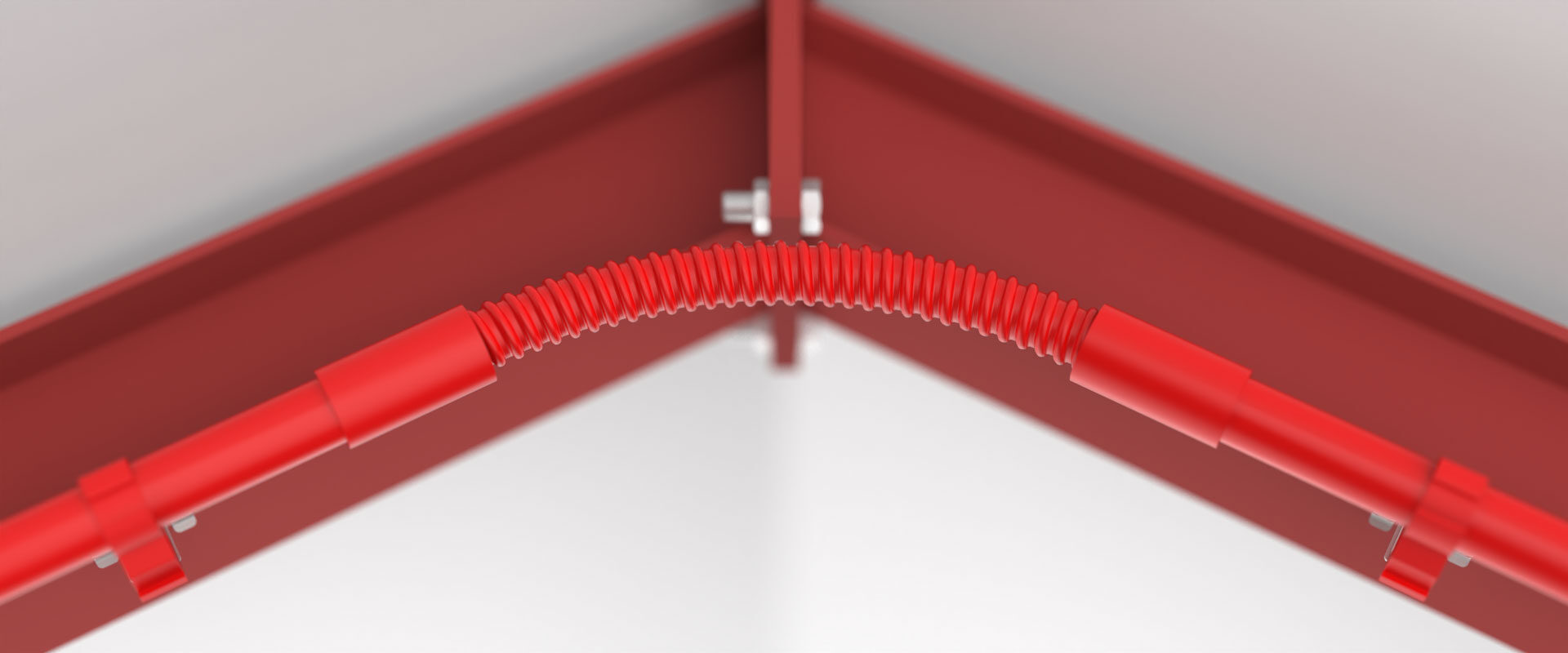

Sampling Pipe Contraction

Environmental factors can cause subtle building movement. This must be factored in when designing an ASD pipe network. Using flexible tubes and expansion sockets will help the system maintain its integrity when building movement occurs.

Obstacles

Beams and apex roofs can make routing aspirating pipe networks difficult. Flexible pipes can be used to overcome obstacles while maintaining optimal airflow compared to shared degree pipe fittings.

Contamination

The VESDA In-Line Filter can help reduce contamination to provide more reliable detection and prolong the life of the detector.

Blow-back Air Maintenance

Warehouses are typically dusty and dirty environments with lots of airborne contaminants. Manually operated cleaning valves or the automatic aspiration maintenance system, Blazer, can help to keep pipework clean and operational.

High Level Functional Smoke Testing

High-ceiling constructions can mean that smoke testing aspirating smoke detection can require additional access equipment. Dropping the pipe network down to ground level and installing a test point can make testing easier. Alternatively, the Scorpion ASD tester, a functional remote smoke detector test system for aspirating smoke detection (ASD), can be used.

Why Choose Eurofyre?

- Xtralis Gold Partner

- Eurofyre has ‘Gold Channel Partner’ status with Xtralis – the market leader in aspirating smoke detection. This recognition displays our level of commitment, including excellent customer service and competitive pricing.

- Complete System Supplier

- Eurofyre is a complete system supplier and has been a major Xtralis technical wholesaler since 2007. This means we can offer expert advice and supply all aspects of fire detection including aspirating smoke detection systems, conventional and addressable fire alarm control panels and linear heat detection.

- Pipework Design

- Eurofyre can also provide assistance with aspirating pipe network design to ensure optimum network performance and installation quality.

- Demonstration and Training

- We have a sophisticated training facility where we offer demonstrations and expert training on a range of systems, including FAAST FLEX aspirating smoke detection systems.

- After-Sales Support

- Eurofyre prides itself on providing after-sales care and support that is second to none. We offer both on-site and telephone assistance to help you ensure that your system is fully operational and working at its best.

For more information about FAAST FLEX, or to discuss any of the other products that Eurofyre has to offer, please feel free to get in touch either by phone on +44 (0) 1329 835 024, by email to [email protected] or via the online enquiry form situated on our contact page.

Don’t forget you can follow us on LinkedIn, Twitter and Facebook or sign up to our newsletter (in the footer below) to receive all the latest information from Eurofyre.