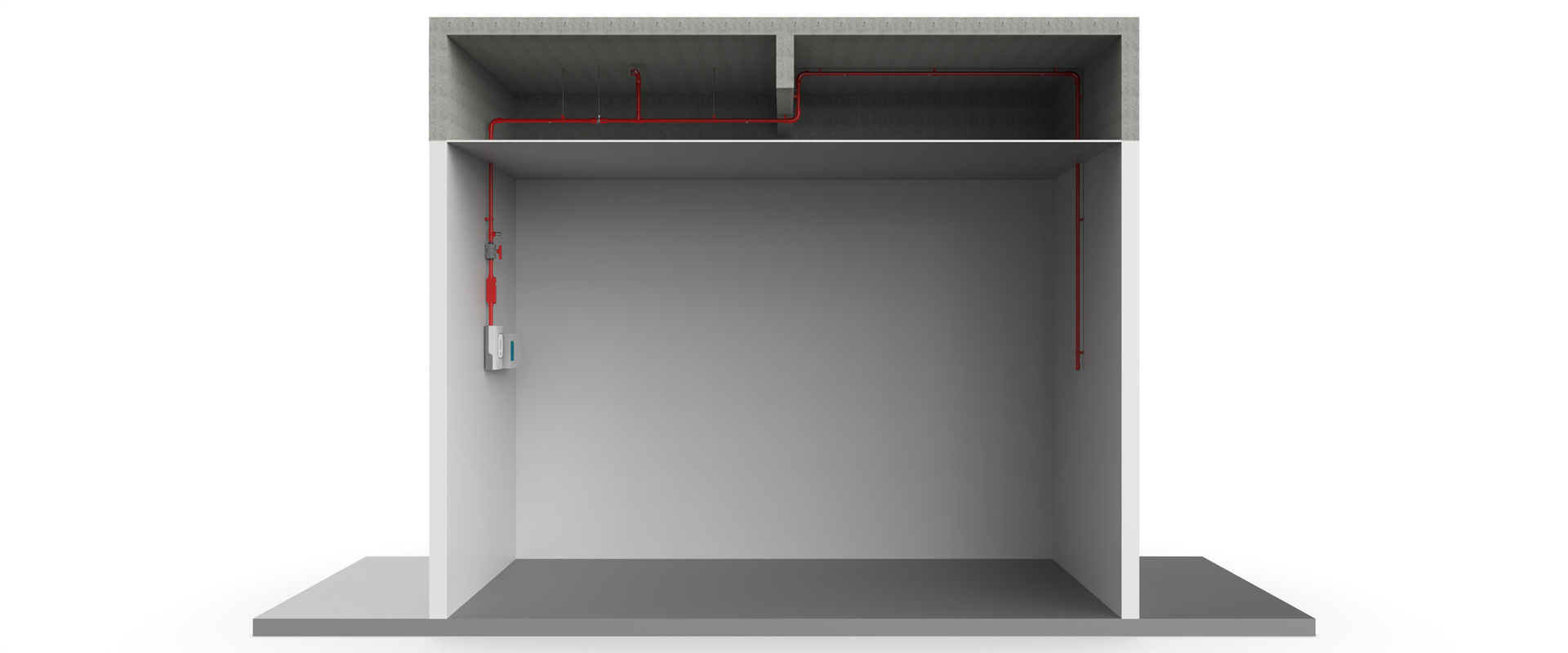

Ceiling voids are created when an additional suspended ceiling is installed, hanging from the structural floor slab above. These voids can be found in a variety of building types, including commercial properties, schools and hospitals. Ceiling voids are useful for concealing a variety of systems and elements such as wiring, HVAC services, security devices, detectors, sound and light fittings, as well as active fire protection measures that would otherwise be visible.

What are the Risks?

There are various fire risks associated with ceiling voids, some of which include:

- Electrical wiring

- Ceiling voids often contain electrical wiring. If the wiring is damaged, poorly installed or overloaded they can cause a fire.

- Combustible materials

- Ceiling voids often contain combustible materials, such as insulation, wood or paper, which can catch fire and spread rapidly.

- HVAC systems

- Heating, ventilation and air conditioning (HVAC) systems in ceiling voids can pose a fire risk if they are not properly maintained, or if there is a malfunction that causes a spark or ignition.

- Poor fire resistance

- If the suspended ceiling is not designed or installed correctly, it may not provide adequate fire resistance. This could allow fire to spread quickly through the ceiling void and into other parts of the building.

- Blocked fire protection systems

- Ceiling voids often contain active fire protection systems, such as sprinklers or fire alarms. If these systems become blocked or are not maintained properly, they may not function as intended during a fire, increasing the risk of damage and injury.

What are the Challenges?

There is also a number of challenges that arise when designing suitable fire detection for ceiling voids:

- Limited access

- Ceiling voids can be difficult to access, particularly if they are narrow or located at a high level. This can make it challenging to install, maintain or test fire detection systems in these spaces.

- Concealed fires

- Fires that start in ceiling voids can be difficult to detect, especially if the fire is smouldering and does not produce visible smoke or flames.

- False alarms

- Ceiling voids can be dusty, which can cause smoke detectors to trigger false alarms. This can be particularly problematic if the ceiling voids contain sensitive equipment that could be damaged by water or other fire suppression measures.

- Ceiling voids can contain a variety of electrical and mechanical systems that can interfere with fire detection equipment. It is important to ensure that fire detection systems are installed and maintained correctly to avoid interference.

- Integration

- Fire detection systems in ceiling voids need to be integrated with other building systems such as HVAC and electrical systems. This integration can be complex and may require specialised knowledge and equipment.

Aspirating Smoke Detection

Aspirating smoke detection (ASD) uses a network of pipes to draw air into a detection chamber. The detection elements then analyse the air for the presence of smoke particles. ASD offers several benefits over other fire alarm detection types, including early detection, configurable sensitivity, flexibility, versatility and ease of maintenance.

ASD can detect smoke particles in the air at an early stage, allowing for faster response times and potentially reducing the spread of fire.

ASD can be used in a variety of environments, including those with harsh or changing conditions such as ceiling voids. It can also detect a variety of types of smoke particles, including those produced by smouldering fires, which may not be detected by other types of fire detection systems.

ASD is easy to maintain; detection pipes can be cleaned and replaced without disrupting the system and automatic maintenance systems are available to maintain the effective operation of the system.

FAAST FLEX

FAAST FLEX aspirating smoke detectors are well suited for use in a wide range of applications. Their pre-engineered pipe network design, out-of-the-box operation and built-in configuration and control mechanisms make them highly adaptable to various environments, while precise aspirating smoke detection technology ensures constant detection with minimal false alarms. Additionally, their modular design and field-replaceable components allow for easy in-field servicing and maintenance.

FAAST FLEX Design Considerations

FAAST FLEX provides easy to install high-sensitivity air sampling smoke detection. It is capable of detecting fires very quickly to warn the user at the earliest possible stage of fire. Flexible sampling pipes can be easily installed in hard-to-reach void spaces to provide continuous air sampling, allowing for early detection of a potential fire. FAAST FLEX is highly customisable and can be tailored to the specific needs of the building or space being protected, making it a versatile and effective solution for void space protection.

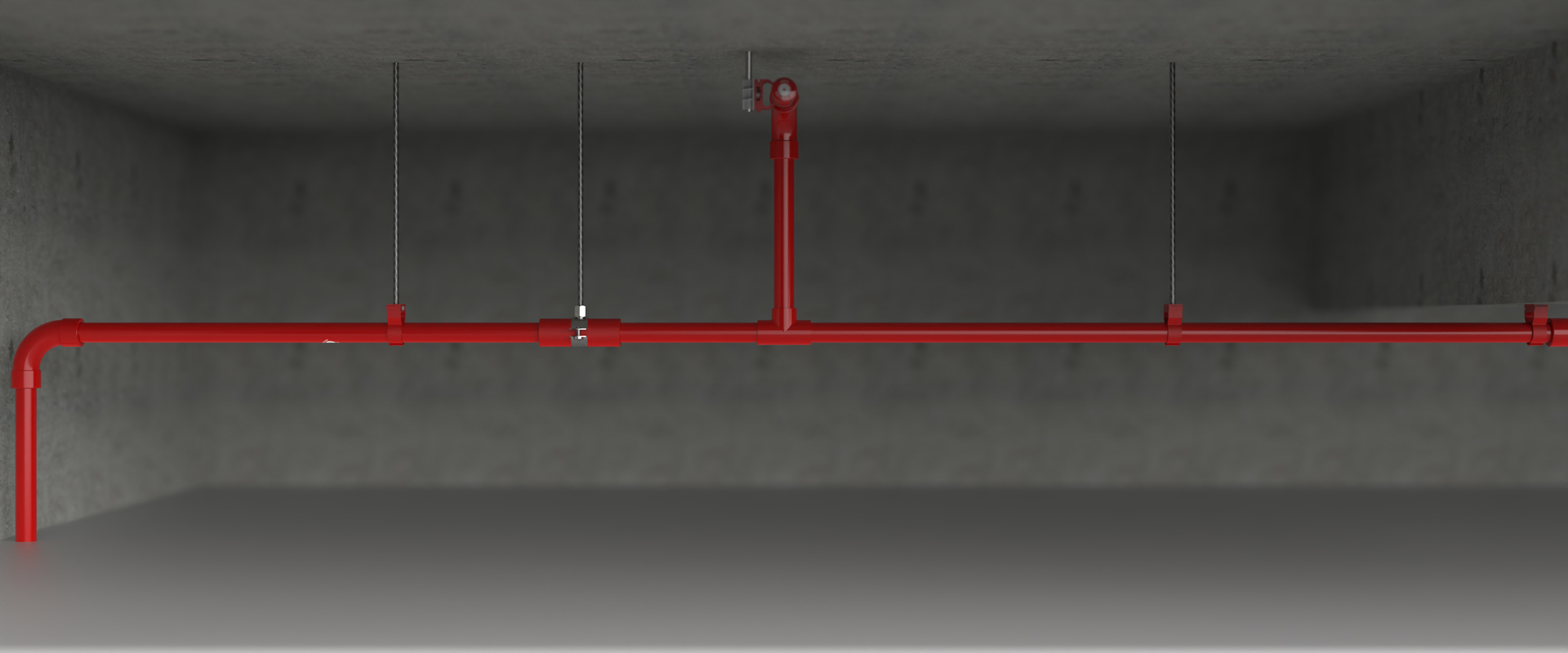

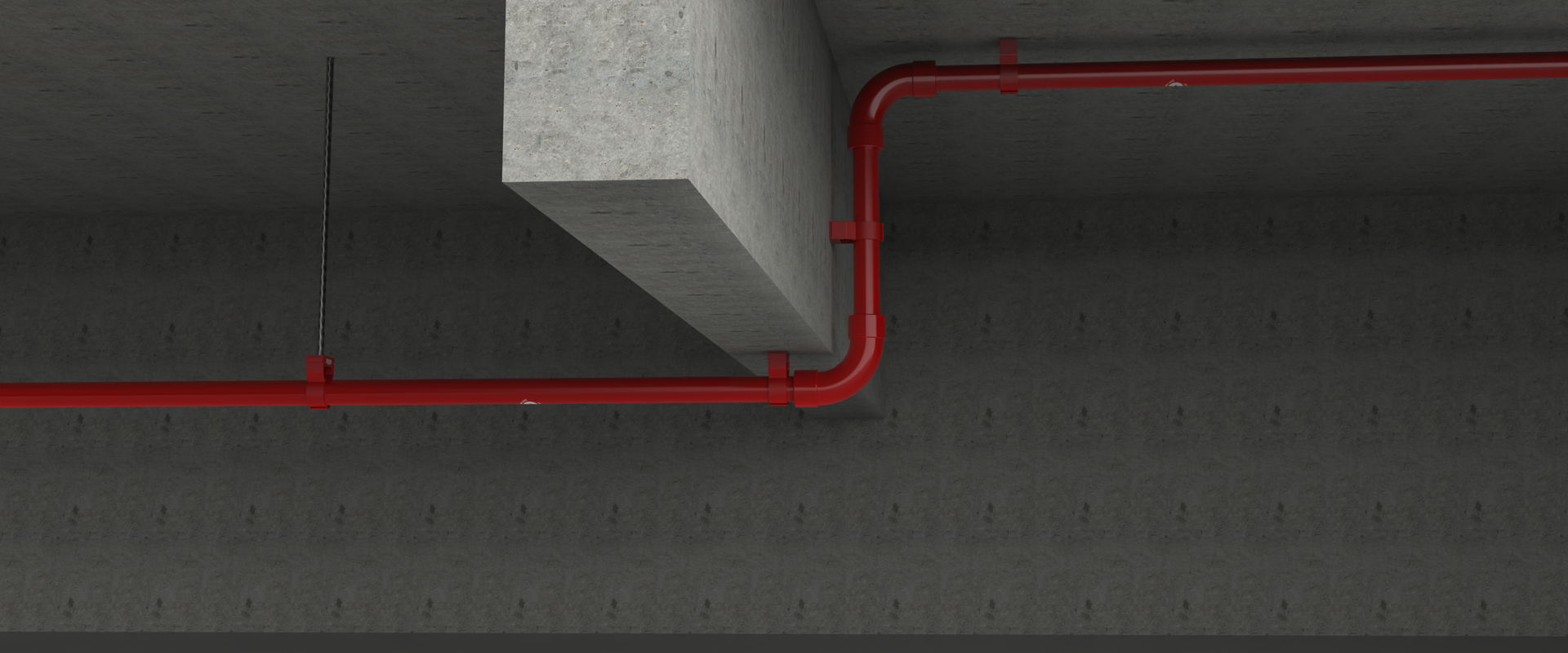

Compartments

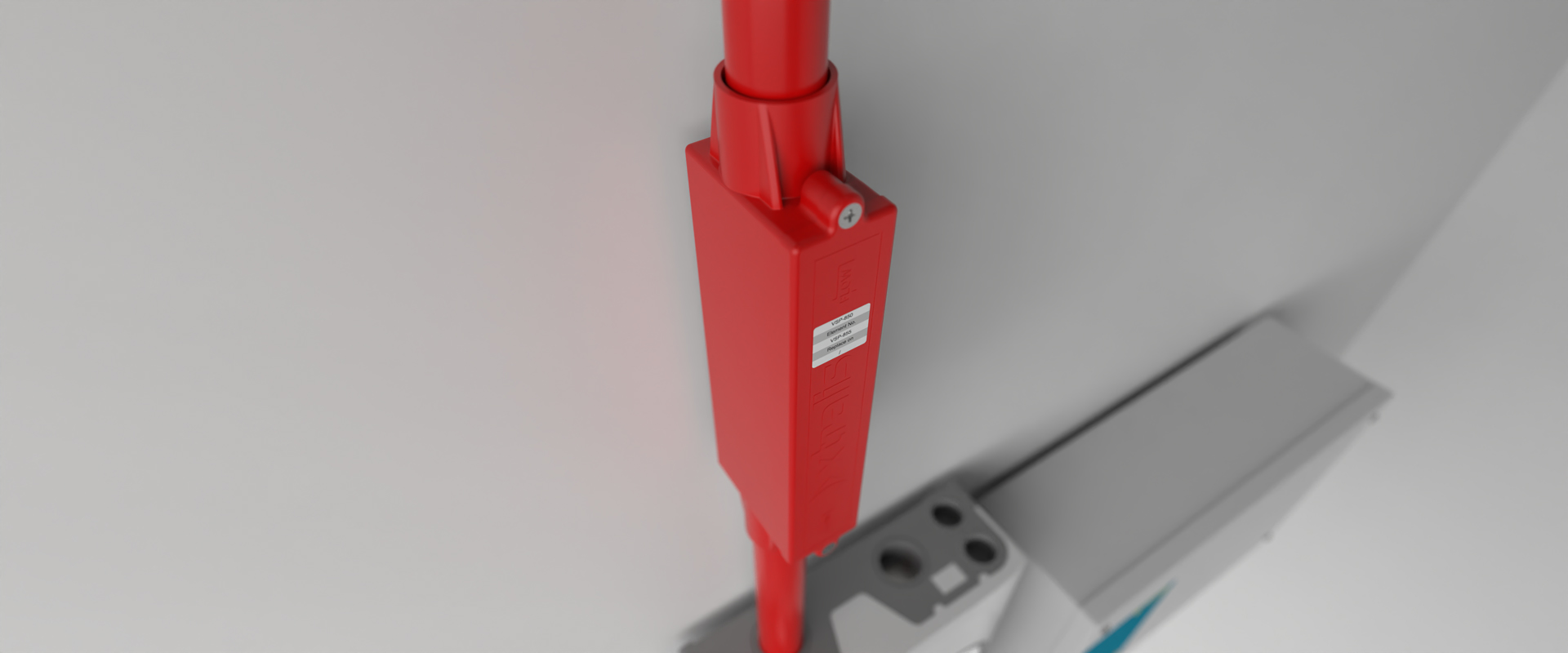

In some buildings, ceiling voids may be divided into compartments due to the presence of walls, beams or other obstructions. To ensure that the FAAST Flex system detects smoke particles from each compartment, pipe upstands can be used within the void space. These upstands are vertical pipes that are installed within each compartment and extend above the height of the surrounding compartment walls. The upstands allow smoke and heat to rise up and enter the air sampling pipe network, ensuring that the FAAST FLEX system can detect the presence of smoke within each compartment.

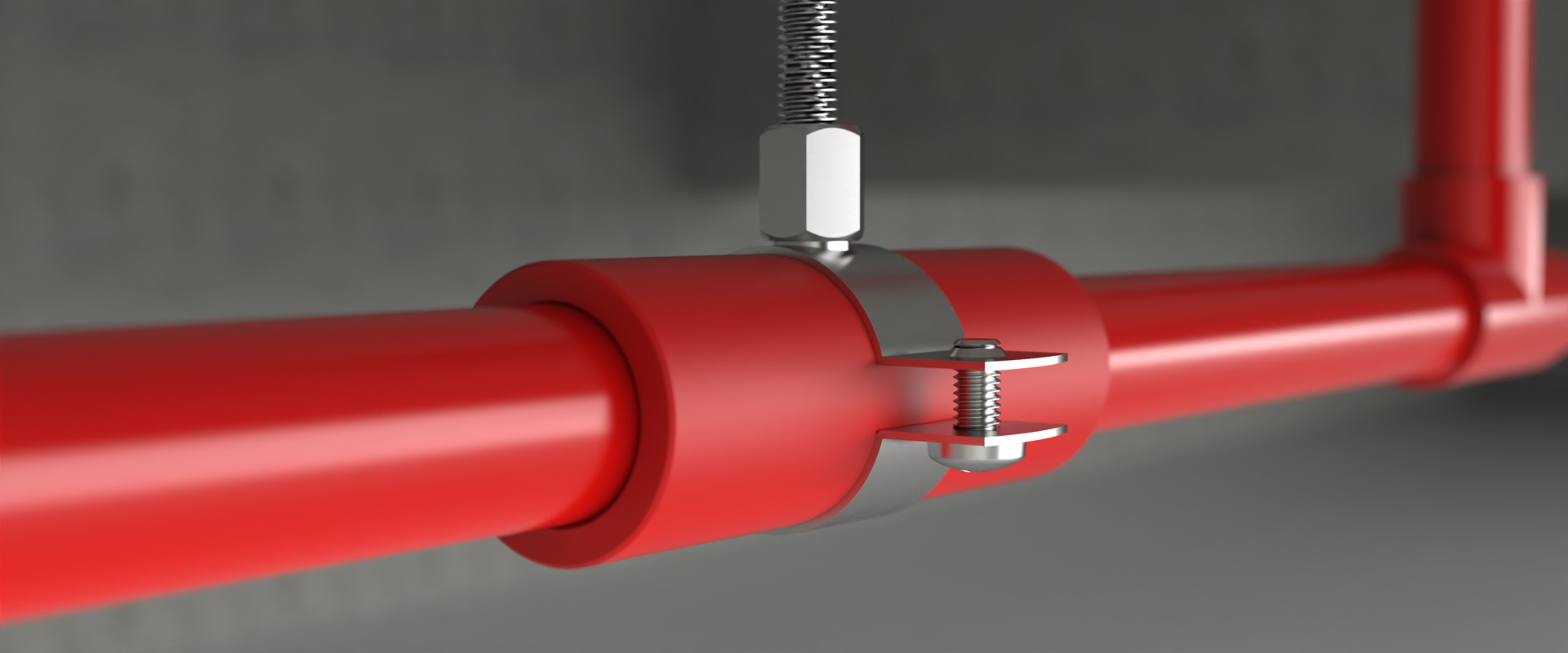

Sampling Pipe Fixing Clips

We have a variety of aspirating pipe clips available to make securing aspirating smoke detection pipe simple, including rod adapters that are available for mounting pipework directly to ceilings.

Sampling Pipe Contraction

Environmental factors can cause subtle building movement. This must be factored in when designing an ASD pipe network. Using flexible tubes and expansion sockets will help the system maintain its integrity when building movement occurs.

Obstacles

Ceiling voids can contain a number of obstacles. Flexible pipes can be used to overcome obstacles while maintaining optimal airflow compared to shared degree pipe fittings.

Contamination

Void spaces in buildings can be contaminated by dust, moisture, chemicals and pests, which can obstruct the flow of air and affect the performance of aspirating smoke detection systems.

The VESDA In-Line Filter can help reduce contamination to provide more reliable detection and prolong the life of the detector.

Blow-back Air Maintenance

Ceiling voids can be dusty and dirty environments with lots of airborne contaminants. Manually operated cleaning valves or the automatic aspiration maintenance system, Blazer, can help to keep pipework clean and operational.

Inaccessible Functional Smoke Testing

A floor level test point, a sampling point located at floor level within a void space, can provide easy access for testing. Using a floor level test point and Scorpion ASD tester, the FAAST FLEX smoke detection system can be tested from the floor level, without having to access the ceiling void space.

Why Choose Eurofyre?

- Xtralis Gold Partner

- Eurofyre has ‘Gold Channel Partner’ status with Xtralis – the market leader in aspirating smoke detection. This recognition displays our level of commitment, including excellent customer service and competitive pricing.

- Complete System Supplier

- Eurofyre is a complete system supplier and has been a major Xtralis technical wholesaler since 2007. This means we can offer expert advice and supply all aspects of fire detection including aspirating smoke detection systems, conventional and addressable fire alarm control panels and linear heat detection.

- Pipework Design

- Eurofyre can also provide assistance with aspirating pipe network design to ensure optimum network performance and installation quality.

- Demonstration and Training

- We have a sophisticated training facility where we offer demonstrations and expert training on a range of systems, including FAAST FLEX aspirating smoke detection systems.

- After-Sales Support

- Eurofyre prides itself on providing after-sales care and support that is second to none. We offer both on-site and telephone assistance to help you ensure that your system is fully operational and working at its best.

For more information about FAAST FLEX, or to discuss any of the other products that Eurofyre has to offer, please feel free to get in touch either by phone on +44 (0) 1329 835 024, by email to [email protected] or via the online enquiry form situated on our contact page.

Don’t forget you can follow us on LinkedIn, Twitter and Facebook or sign up to our newsletter (in the footer below) to receive all the latest information from Eurofyre.