Lithium-ion batteries are rechargeable energy storage devices. They are favoured for storage due to their high energy density, compact size, and lightweight nature. These batteries are widely used in various applications, including portable electronics, electric vehicles, and energy storage systems.

In the context of storage, lithium-ion batteries are employed to capture and store electricity from renewable sources like solar or wind power. This enables a more reliable and consistent power supply, balancing the intermittent nature of renewable energy generation. They also play a vital role in load levelling, peak shaving, and backup power applications, enhancing energy efficiency and resilience in electrical grids.

What are the Risks?

There are several fire risks associated with Battery Energy Storage Systems (BESS) and their operation:

- Thermal Runaway

- Battery Energy Storage Systems use large quantities of lithium-ion batteries, which are susceptible to thermal runaway. If one battery cell experiences thermal runaway, it can rapidly spread to neighbouring cells, leading to a significant fire event.

- Battery Aging and Degradation

- Over time, the performance and safety of lithium-ion batteries in a BESS can degrade. Ageing batteries may become more prone to internal shorts, which can result in overheating, thermal runaway, and potential fires.

- Manufacturing Defects

- Faulty manufacturing processes or defects in the battery cells used in a BESS can increase the risk of fire.

- Electrical Faults

- Battery Energy Storage Systems involve complex electrical systems, including inverters, power converters, and monitoring equipment. Electrical faults such as short circuits, overloads, or electrical arcing can trigger fires within the BESS infrastructure.

- External Factors

- External factors like extreme temperatures, environmental contaminants, natural disasters, or physical damage to the BESS equipment can pose fire risks. These factors can compromise the integrity of the system, leading to potential electrical faults or thermal events.

What are the Challenges?

Designing a fire detection solution specifically for Battery Energy Storage Systems (BESS) presents several challenges:

- Unique Fire Behaviour

- Lithium-ion battery fires in Battery Energy Storage Systems can exhibit unique fire behaviour, including intense heat, flammable electrolyte release, and the potential for re-ignition. Designing a fire detection solution that can accurately detect and respond to these specific fire characteristics is challenging.

- Early Fire Detection

- Early detection of fires in a BESS is crucial to prevent the rapid spread of thermal runaway. However, detecting fires at an early stage within a large-scale BESS installation can be challenging due to the complex layout, high-density battery arrays, and potential obstructions.

- False Alarm Minimisation

- BESS environments may have operational conditions that can trigger false alarms, such as high temperatures, humidity, or dust. Designing a fire detection solution that can effectively differentiate between genuine fire events and false alarms is essential to avoid unnecessary disruptions and ensure reliable performance.

- Monitoring System Integration

- Integrating the fire detection solution with the overall monitoring system of the BESS can be complex. Effective communication and compatibility between the fire detection system, battery management system, and other monitoring components are crucial for seamless operation and response during a fire incident.

- Maintenance and Calibration

- Ensuring the ongoing reliability and accuracy of the fire detection solution in a BESS environment can be challenging. Regular maintenance, calibration, and testing of the detection system, including smoke detectors, thermal sensors, and gas sensors, are essential but may be complicated due to the size and configuration of the BESS installation.

What is the Solution?

There are a number of detection types available that are suitable for protecting a BESS from fire. However, a two-pronged approach can provide a solution that can detect potential fires quickly and effectively with reduced risk of false alarm.

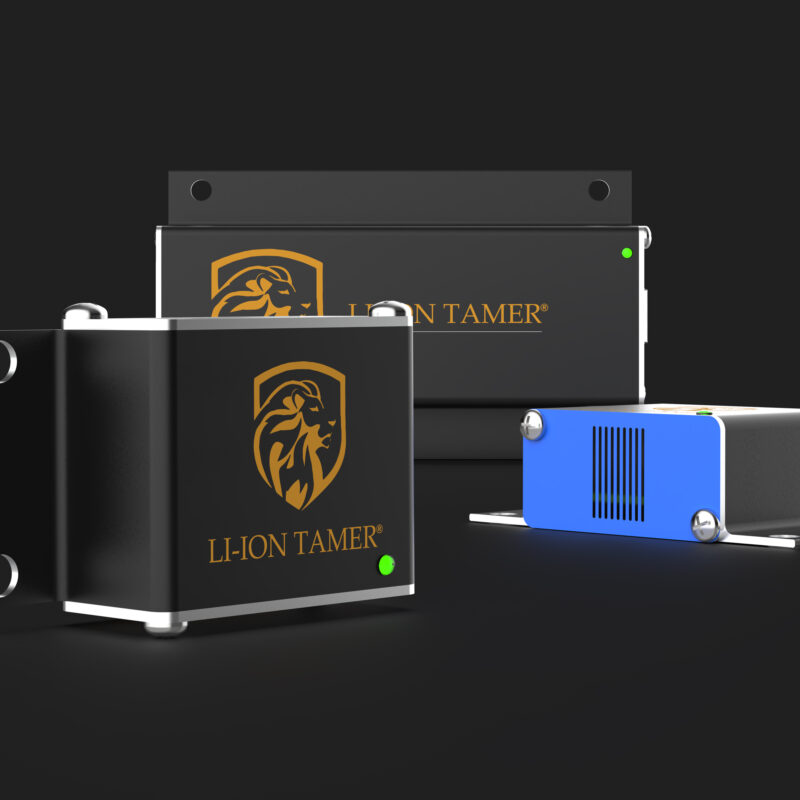

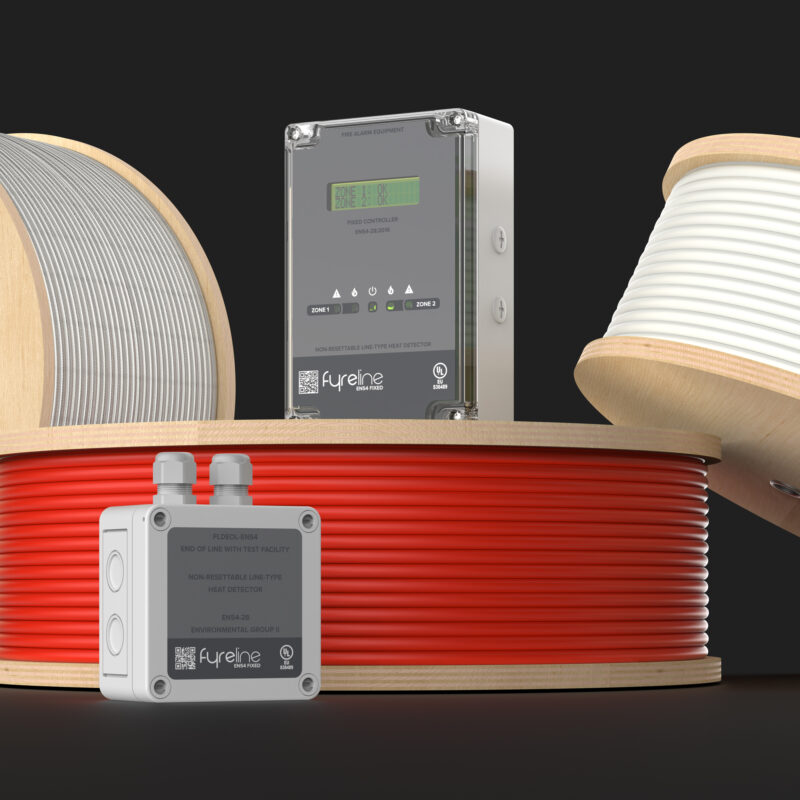

In particular, there are two fire detection systems on the market that, when combined, can provide the perfect solution for protecting a BESS from fire. They are the Li-ion Tamer from Honeywell and FyreLine EN54 from Eurofyre.

Li-ion Tamer

The Li-ion Tamer GEN 3 battery monitoring system reliably alerts the user to the early signs of failing lithium-ion batteries (LIBs) by detecting the battery electrolyte vapours that are released in the off-gas stage of failure. This allows facility managers to respond to impending thermal runaway events during the very early stages of failure.

This unique detection technology also provides multi-point temperature and humidity measurements for improved environmental control and situational awareness across a wide range of applications. It is highly scalable making it a cost-effective solution for modular, containerised and large scale lithium-ion battery installations.

FyreLine EN54 Fixed Linear Heat Detection

Linear Heat Detection (LHD) uses heat sensing cables to detect rises in temperature. It is unaffected by airflow or contaminants and can provide fast and reliable detection in almost any environment. When the heat sensing cable reaches its rated temperature, the LHD controller sends a signal to the fire alarm control panel and shows the exact location of the event on its LCD panel.

Fyreline EN54 is easy to install, adaptable to different areas, and can withstand harsh environments. It is compliant with the EN54-28 standard and can provide reliable and efficient fire detection for Battery Energy Storage Systems.

When designing a fire detection system for a BESS, Li-ion Tamer can be used as the primary detection to monitor off-gas events, and FyreLine heat sensing cable can be installed around the cells to monitor for overheat events. Using these two detection systems together ensures that potential fires can be caught during the earliest possible stages allowing any issues to be dealt with quickly, thus preventing catastrophe.

The Benefits

- Early Warning

Sophisticated algorithms provide early detection of lithium-ion battery off-gassing. - Increased System Visibility

Quick and easy configuration and monitoring via user interface software provide low-cost commissioning and setup. - Lower Maintenance Cost

Calibration-free detection with extended product lifetime, reduces overall cost of ownership and maintenance. - Enhanced Environmental Monitoring

Temperature and humidity detection at each detection node provides granular environmental monitoring of the protected space. - Improved Event Data Logging

Increased storage capabilities of the controller gather extensive event logging for more insight during post-event evaluation.

- Fixed Heat Detection

Provides fast and reliable detection at a fixed temperature of 78°C or 88°C. - Increased Coverage

Supports two zones of up to 1000m and can be connected to either a conventional or addressable fire alarm control panel. - Pinpoint Accuracy

Provides accurate location of overheat events enabling the end user to investigate the threat and take the necessary action. - 2 Modes of Operation

Each zone can operate either independently of each other, or in interlock mode. - Fully Approved for the EEA

All products in the FyreLine EN54 range are approved for use within the European Economic Area (EEA) and comply with the EU’s New Approach Directives and show the CE mark to indicate that they fulfil the requirements of relevant European product directives.

Typical Wiring Diagram

Li-ion Tamer Gen 3

Li-ion Tamer GEN 3 is suitable for a variety of different lithium-ion battery systems. Typically, a Li-ion Tamer will consist of the following:

- Monitoring sensors installed at the battery racks to monitor off-gas events.

- Reference sensors installed to monitor the ambient environment and air inlets to prevent false positive signals.

- One or more hubs installed local to their respective zone of sensors.

- Controller and Ethernet switch for aggregating sensor signals (optional PoE switches for distributing power to the system).

FyreLine EN54 Fixed LHD

A FyreLine EN54 Fixed Linear Heat Detection system is comprised of three key components: FyreLine EN54 Fixed LSZH LHD Cable, FyreLine EN54 Fixed Controller and FyreLine EN54 Fixed End Of Line (EOL).

FyreLine EN54 Fixed LSZH LHD Cable is installed in the protected area and used to detect overheat events. The controller sits between the heat sensing cable and the fire alarm control panel to monitor the condition of the cable and relay any events to the fire alarm control panel. The FyreLine EN54 EOL is used to terminate the other end of the heat sensing cable.

Why Choose Eurofyre?

- Complete System Supplier

- Eurofyre supplies all aspects of fire detection and its associated safety products, including battery rack monitoring systems and linear heat detection, and can provide expert advice and consultation.

- Demonstration and Training

- We offer demonstrations and expert training on a range of systems, including Li-ion Tamer rack monitoring systems and linear heat detection, in our very own sophisticated training facility.

- After-Sales Support

- Eurofyre offers both on-site and telephone support to assist you in ensuring that your system is fully functional and operating at maximum efficiency. Our after-sales care and support are second to none.

For more information about Li-ion Tamer Rack Monitoring systems, FyreLine Fixed EN54 or to discuss any of the other products that Eurofyre has to offer, please feel free to get in touch either by phone on +44 (0) 1329 835 024, by email to [email protected] or via the online enquiry form situated on our contact page.

Don’t forget you can follow us on LinkedIn, Twitter and Facebook or sign up to our newsletter (in the footer below) to receive all the latest information from Eurofyre.