Suspended ceilings, also known as dropped or false ceilings, are secondary ceilings that are suspended from the structure above. Suspended ceilings do not just create a more aesthetic finish, they also create a void that provides a useful space.

Ceiling voids have many practical uses, including providing space to conceal heating, ventilation and air conditioning (HVAC) ducts, pipes for plumbing, and electrical wiring as well as providing a platform for the installation of light fittings, smoke and fire detectors, speakers, CCTV, motion sensors and more.

What are the Risks?

Quite often, ceiling voids are full of various electrical cables and pipes that are hidden from view. If electrical cabling becomes faulty or overheats, the risk of fire is greatly increased.

Likewise, if pipes used to transport liquid such as heating or water pipes become damaged or suffer wear and tear, the resulting spillage could come into contact with electrical cables which, again, significantly increases the risk of fire.

What are the Challenges?

Maintenance

Ceiling voids are often oddly shaped, confined spaces with limited access. This means that access for maintenance may be very restricted, making regular upkeep difficult.

Dusty or Dirty Environments

As ceiling voids are rarely accessed or cleaned, they can be dirty or dusty environments. Some more traditional detection types may struggle to differentiate between dust and smoke, rendering them unreliable or prone to trigger false or nuisance alarms.

Air Conditioning and Ventilation

Air conditioning and ventilation in ceiling voids can delay smoke reaching traditional smoke detectors, thus delaying reaction and response times.

What is the Solution?

Linear heat detection provides the perfect fire detection solution for ceiling voids. Linear heat detection cable can be installed alongside electrical cabling in cabling trays or along pipework and ducting. It provides a low-maintenance solution that does not require regular access. Linear heat detection is not affected by dust or dirty environments and does not rely on stable airflow to work efficiently.

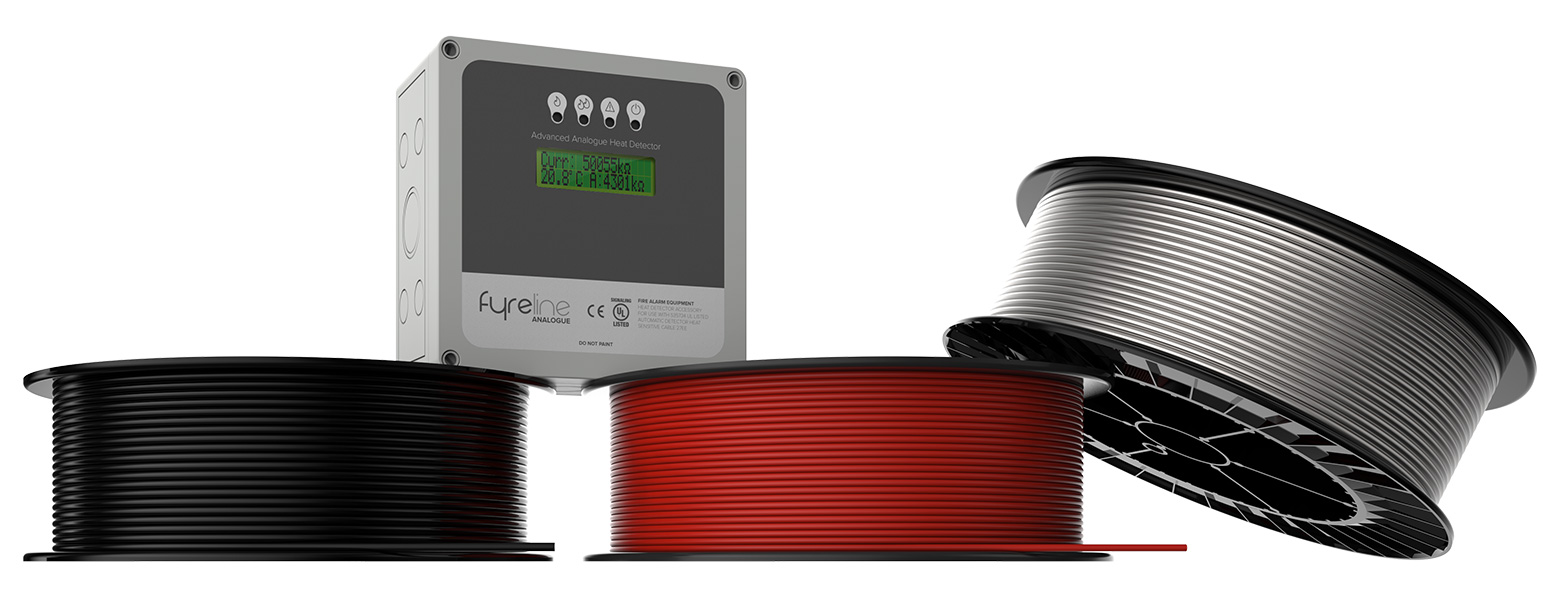

FyreLine Linear Heat Detection

FyreLine linear heat detection is capable of detecting heat anywhere along the length of heat sensing cable and is designed for use in commercial and industrial applications.

A variety of coatings and sheaths are available to ensure optimal detection in even the most challenging environments, including those where:

- chemicals or hazardous hydrocarbons may be present;

- the cable may be subject to mechanical abrasion or;

- the cable is exposed to direct sunlight.

FyreLine is cost-effective, easy to install and maintain and is available in two types – Analogue and Digital.

FyreLine Digital Linear Heat Detection

FyreLine Digital provides fixed temperature heat sensing and is available with four different temperature ratings; 68°C, 88°C, 105°C or 185°C.

Once FyreLine digital heat sensing cable reaches its rated temperature it sends a signal to the fire alarm control panel to indicate that fire, or excessive heat, has been detected.

FyreLine Analogue Linear Heat Detection

FyreLine Analogue heat sensing cable continually monitors for increases in temperature. Once the cable reaches its predetermined temperature, an alarm signal is sent to the fire alarm control panel.

FyreLine Analogue also provides the ability to set a pre-alarm temperature, allowing potential fires to be investigated before a full alarm is raised.

For more information about the FyreLine Linear Heat Detection System, or to discuss any of the other products that Eurofyre have to offer, please feel free to get in touch either by phone on +44 (0) 1329 835 024, by email to [email protected] or via the online enquiry form situated on our contact page.

Don’t forget you can follow us on LinkedIn, Twitter, Facebook and Google+ or sign up to our newsletter (in the footer below) to receive all the latest information from Eurofyre.