A floating roof storage tank is a type of industrial storage container designed to store liquids, typically petroleum products such as crude oil or refined fuels. Unlike traditional fixed-roof tanks, these tanks have a floating roof that rests on the surface of the liquid, rising and falling with changes in the liquid’s volume.

This floating roof helps minimise the vapour space above the liquid, reducing the risk of evaporation and emissions. These tanks are commonly found in oil refineries, petrochemical plants, and storage facilities, where they are used to store and manage large quantities of liquid products while mitigating environmental concerns and maximising storage efficiency.

Due to the nature of these facilities, and the materials they store, there is a big risk of fire. Therefore, it is essential that suitable fire detection is in place to stop fires spreading and protect assets and lives.

What are the Risks?

There are a number of unique fire risks associated with floating roof storage tanks. These include:

- Lightning Strikes

- Floating roof tanks are often situated outdoors, making them susceptible to lightning strikes. A direct lightning strike can ignite flammable vapours inside the tank, leading to a catastrophic fire.

- Static Electricity

- During the filling or emptying process, static electricity can build up on the floating roof or the surface of the liquid. A discharge of static electricity can spark a fire or explosion when it comes into contact with flammable vapours.

- Mechanical Failures

- Malfunctions or damage to the floating roof’s mechanical components, such as seals or pontoons, can lead to leaks or improper sealing. This can result in the escape of flammable vapours and potential ignition sources.

- Overfilling

- Overfilling a floating roof tank or allowing excessive pressure to build up inside can cause ruptures or leaks in the tank. These leaks can lead to the release of flammable materials and increase the risk of fire.

- Human Error

- Human errors in tank operations, such as improper maintenance, incorrect handling of equipment, or inadequate training, can contribute to fire risks. Mishandling of equipment, such as hoses and valves, can lead to leaks or spills that can ignite.

What are the Challenges?

- False Alarms

- Normal tank operations, such as routine maintenance or product transfers, can generate heat, smoke, or other conditions that might trigger false alarms if not accounted for in the fire alarm system’s design.

- Outdoor Environment

- Floating roof tanks are often located outdoors, exposing them to harsh environmental conditions, including temperature fluctuations, moisture, and dust.

- Tank Movement

- Floating roofs move with the liquid level inside the tank. The fire alarm system must account for this movement to avoid false alarms when the roof rises or falls.

- Remote Locations

- Many floating roof tanks are located in remote areas, making it challenging to establish reliable power sources and communication for the fire alarm system.

- Hazardous Materials

- The tanks often store flammable or volatile materials, which can pose an increased risk of fire and explosion. The fire alarm system must be designed to trigger early warnings and initiate appropriate safety protocols in case of an emergency.

The Solution – FyreLine Digital

FyreLine Digital uses heat sensing cable to detect a change in temperature. Once the cable reaches its rated temperature, it sends a signal to the control panel.

FyreLine Digital Linear Heat Protection can provide the ideal fire detection solution for floating roof storage tanks. It is cost-effective, easy-to-maintain and can provide an accurate and early warning of fire. It is not affected by environmental factors or dust and dirt and a nylon coating helps it to withstand exposure to hazardous hydrocarbons such as fuel oils. A braided stainless steel outer sheath is also available to help protect the cable from mechanical abrasion or damage.

Linear heat detection cable can be configured to accommodate the changes in roof position and configuring the system in interlock mode can reduce the likelihood of false alarms.

Approvals

FyreLine Digital Linear Heat Detection is fully approved by the Underwriters Laboratories (UL). It is also CE marked to show it complies with all the applicable directives including the CPR, EMC and the Low Voltage Directive (LVD).

FyreLine Digital Linear Heat Detection Design Considerations

There are several considerations to be made when designing a linear heat detection system for floating roof tanks. These include controller placement, cable placement, retractable cable methods and detection modes.

FyreLine Digital Linear Heat Detection Controller Placement

FyreLine Digital Linear Heat Detection controllers should be installed in a safe zone, separate from hazardous areas.

Leader Cable

Using fire rated cable as a leader cable to bridge the gap between the heat-sensing cable and the FyreLine control module provides a cost-effective method to connect the sensing cable installed around the floating roof to the controller installed in a safe zone.

FyreLine Digital Linear Heat Detection Cable Placement & Mounting

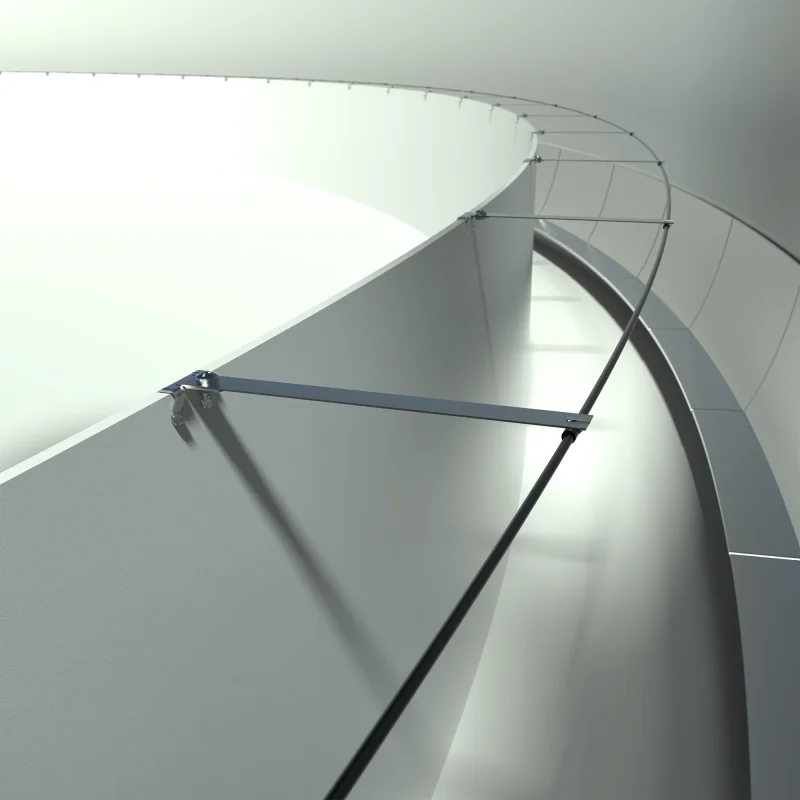

FyreLine Linear Digital Heat Sensing Cable should be installed around the perimeter of the floating tank roof’s seal. It should be positioned and secured above the rim seal, midway between the tank and retaining wall.

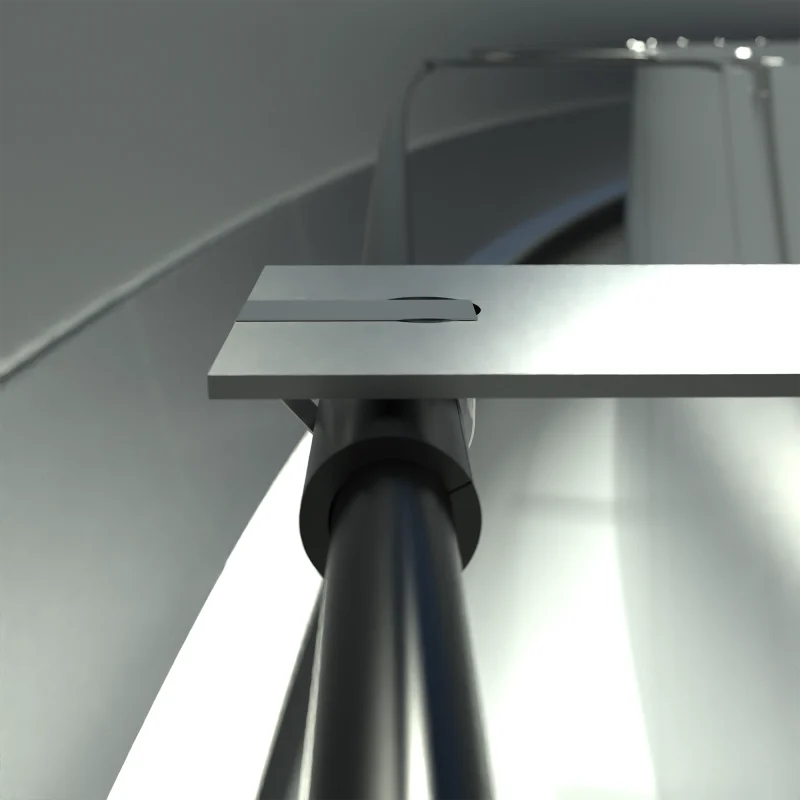

The cable should be mounted using a suitable beam “knock-on clip” and distance piece to ensure that the cable is positioned above the centre of the rim seal as required.

Retractable Cable Methods

When installing heat sensing cable on a floating roof, the upward and downward movement of the roof must be considered. There are two methods of dealing with this:

Retractable Cable with Cable Collector

When using retractable cable with the cable collector, the cable extends and contracts while the cable collector allows the cable to be neatly coiled without getting snagged with the movement of the floating roof.

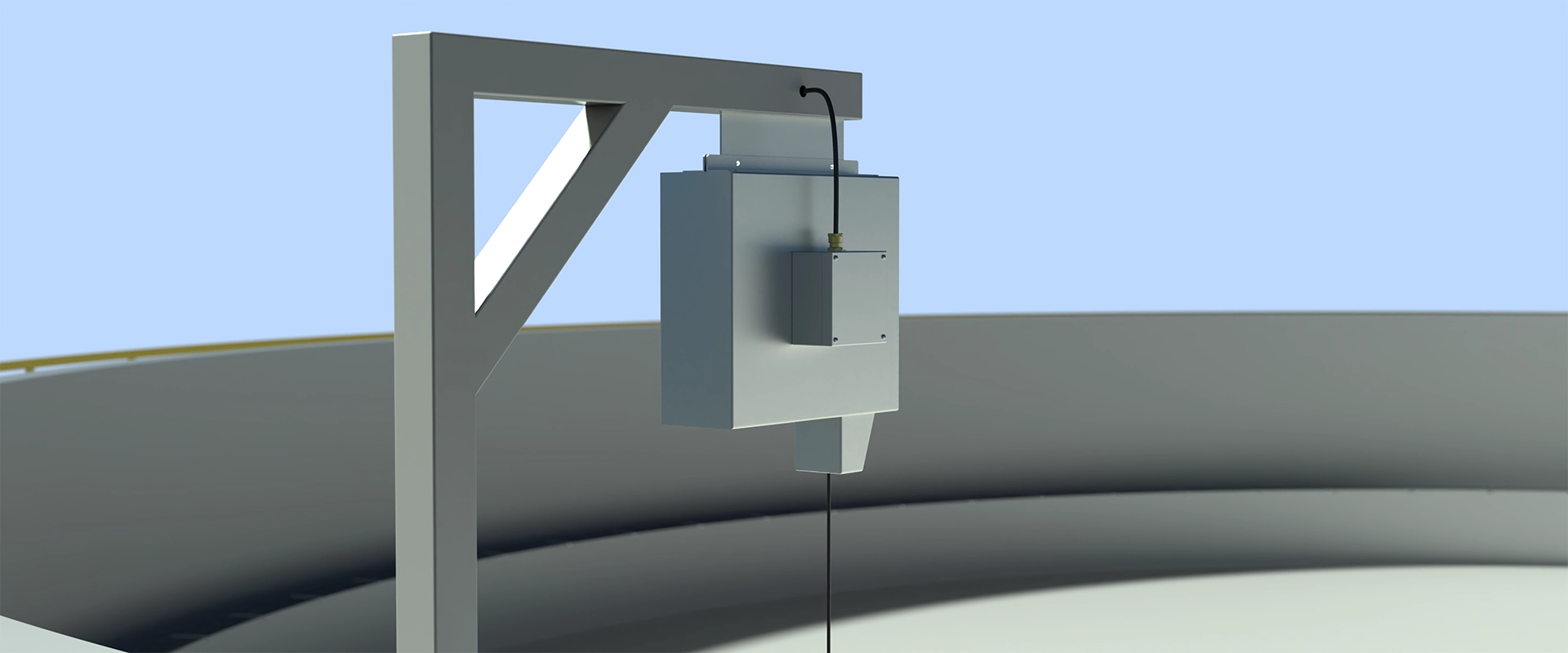

Automatic Cable Reeler

An Automatic Cable Reeler can be installed at the top of the tank with the cable connected to the junction box located on the floating roof. The Automatic Cable Reeler adjusts for the movement of the roof, uncoiling cable when the level falls, and winding the cable when the level rises.

Independent & Interlock/Coincidence Detection

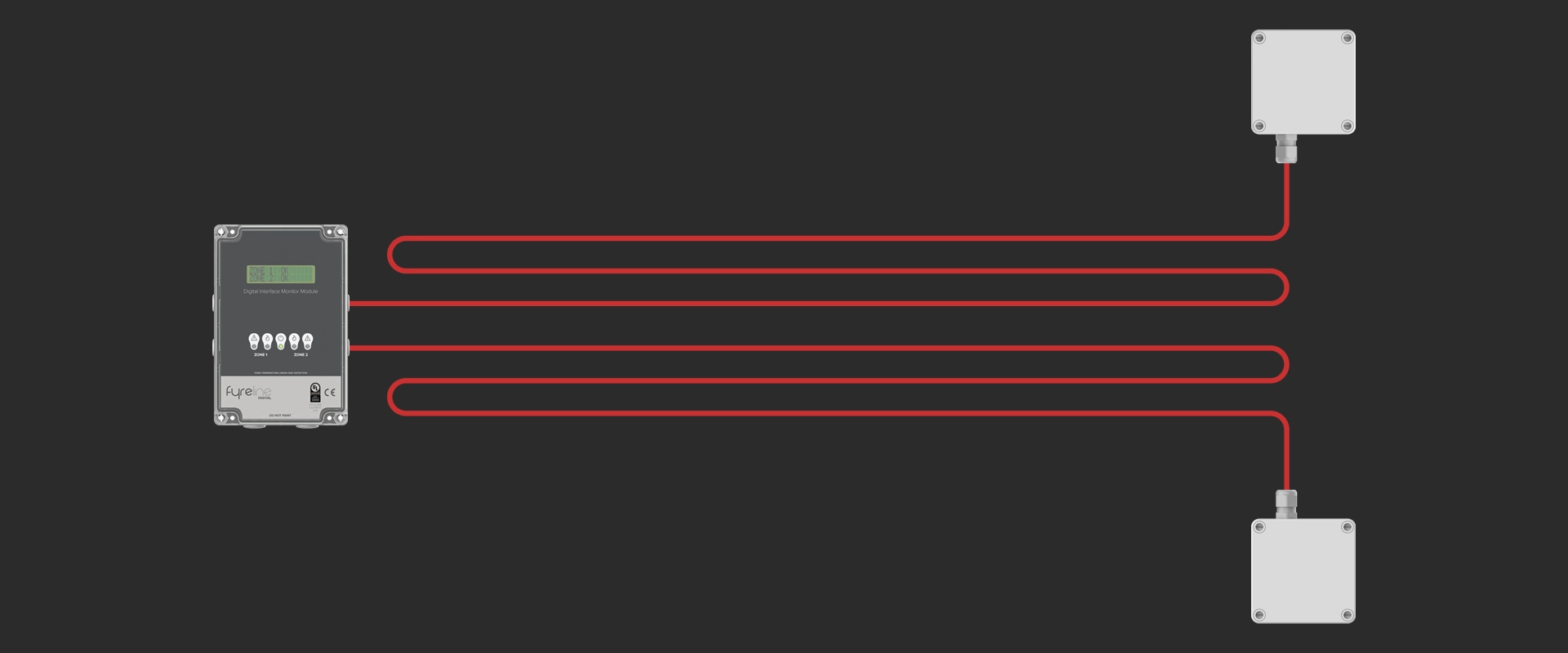

FyeLine Digital can be configured to operate in two different modes; interlock and independent.

Interlock Mode

Interlock mode, also known as coincidence detection, ensures that an alarm is only triggered when an overheat event has occurred. In this mode, two Fixed LHD cables of the same temperature rating should be used for both zones. The alarm output is then only activated when both LHD cables trigger an alarm due to an overheat condition. This prevents alarms that might occur if a mechanical or other issue has caused only one of the sensing cables to trigger an alarm.

Independent Mode

In this mode each zone operates independently. When a fault or overheat condition occurs in a zone, the corresponding fault or alarm output is triggered. In this mode, each zone can contain either identical rated temperature LHD cables or two different rated temperature LHD cables.

Downloads

FyreLine Digital Linear Heat Detection Floating Roof Tank Application Guide

Why Choose Eurofyre?

- Complete System Supplier

- Eurofyre manufactures and supplies all aspects of fire detection including linear heat detection and its associated products and can provide expert advice and consultation.

- Demonstration and Training

- We offer demonstrations and expert training on a range of systems, including FyreLine linear heat detection systems, in our very own sophisticated training facility.

- After-Sales Support

- Eurofyre offers both on-site and telephone support to assist you in ensuring that your system is fully functional and operating at maximum efficiency. Our after-sales care and support are second to none.

For more information about FyreLine Linear Heat Detection, or to discuss any of the other products that Eurofyre has to offer, please feel free to get in touch either by phone on +44 (0) 1329 835 024, by email to [email protected] or via the online enquiry form situated on our contact page.

Don’t forget you can follow us on LinkedIn, X and Facebook or sign up to our newsletter (in the footer below) to receive all the latest information from Eurofyre.