When it comes to fire protection, we consider a harsh environment to be any application where extremes in environmental factors or circumstances unique to the protected area pose challenges to the effective detection of fire. In industrial applications in particular, conditions can vary widely, so understanding the characteristics of the environment and the limitations of fire detection equipment is crucial to designing a successful fire detection system.

Many industrial applications can be characterised as a harsh environment due to their processes and settings, from heavy manufacturing, chemical plants, mining and construction, through to power generation, food processing and data centres.

What are the Challenges?

- High temperatures

- Many industries operate at high temperatures, such as steel manufacturing, glass production and foundries, and the heat produced can affect the performance of fire protection systems and materials.

- Corrosive substances

- Chemical plants, refineries, and certain manufacturing processes involve the handling of corrosive substances that can degrade fire protection equipment over time.

- Dust and debris

- Environments with high levels of dust, debris, or particulate matter, such as grain handling facilities or mining operations, can pose challenges for fire detection and suppression systems by obstructing sensors and causing build-up.

- Moisture and humidity

- Environments with high humidity or moisture levels, such as marine facilities or outdoor industrial sites, can affect the reliability of fire protection equipment and may require corrosion-resistant materials.

- Vibrations and mechanical stress

- Heavy machinery, used in mining, construction, or manufacturing, can subject fire protection systems to constant vibrations and mechanical stress, affecting their performance and durability.

What is the Solution?

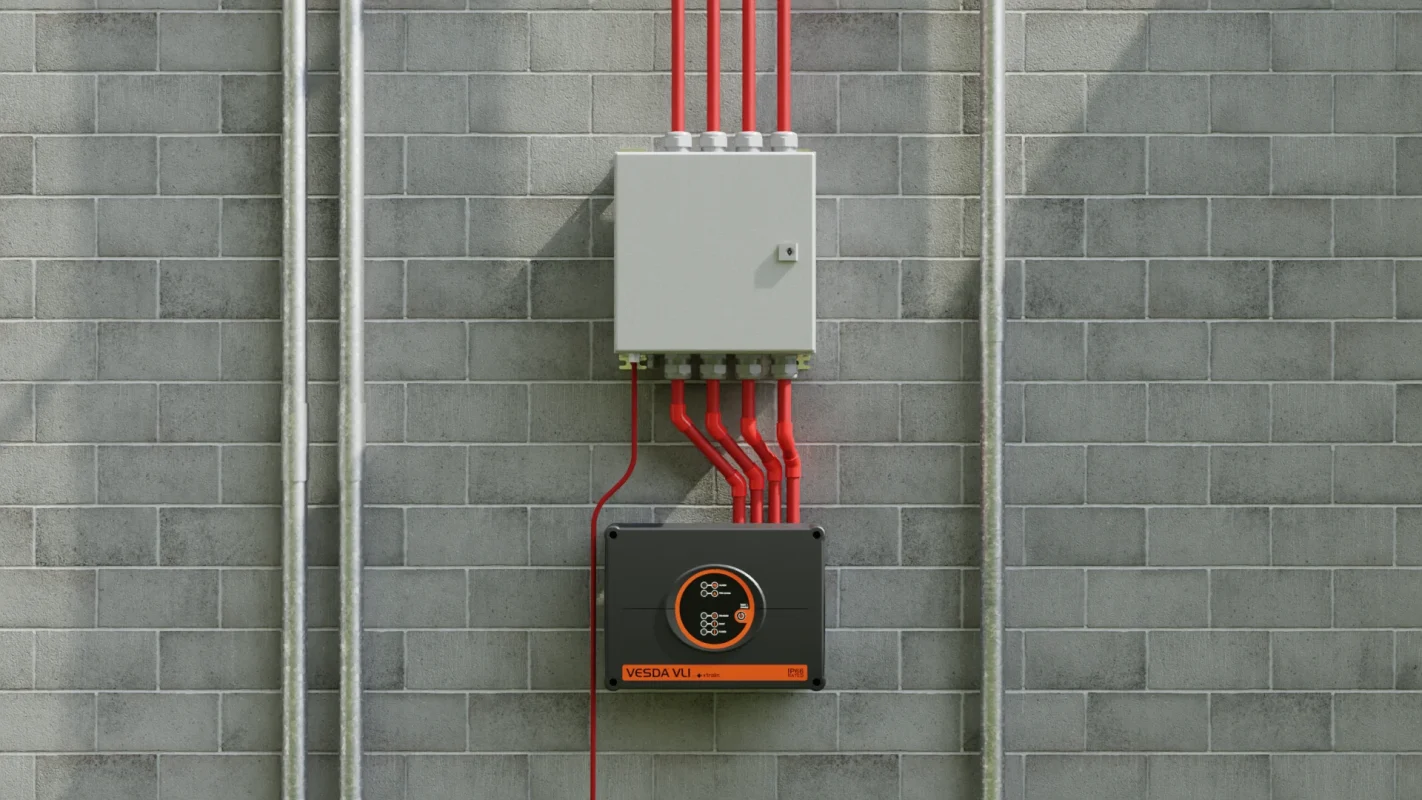

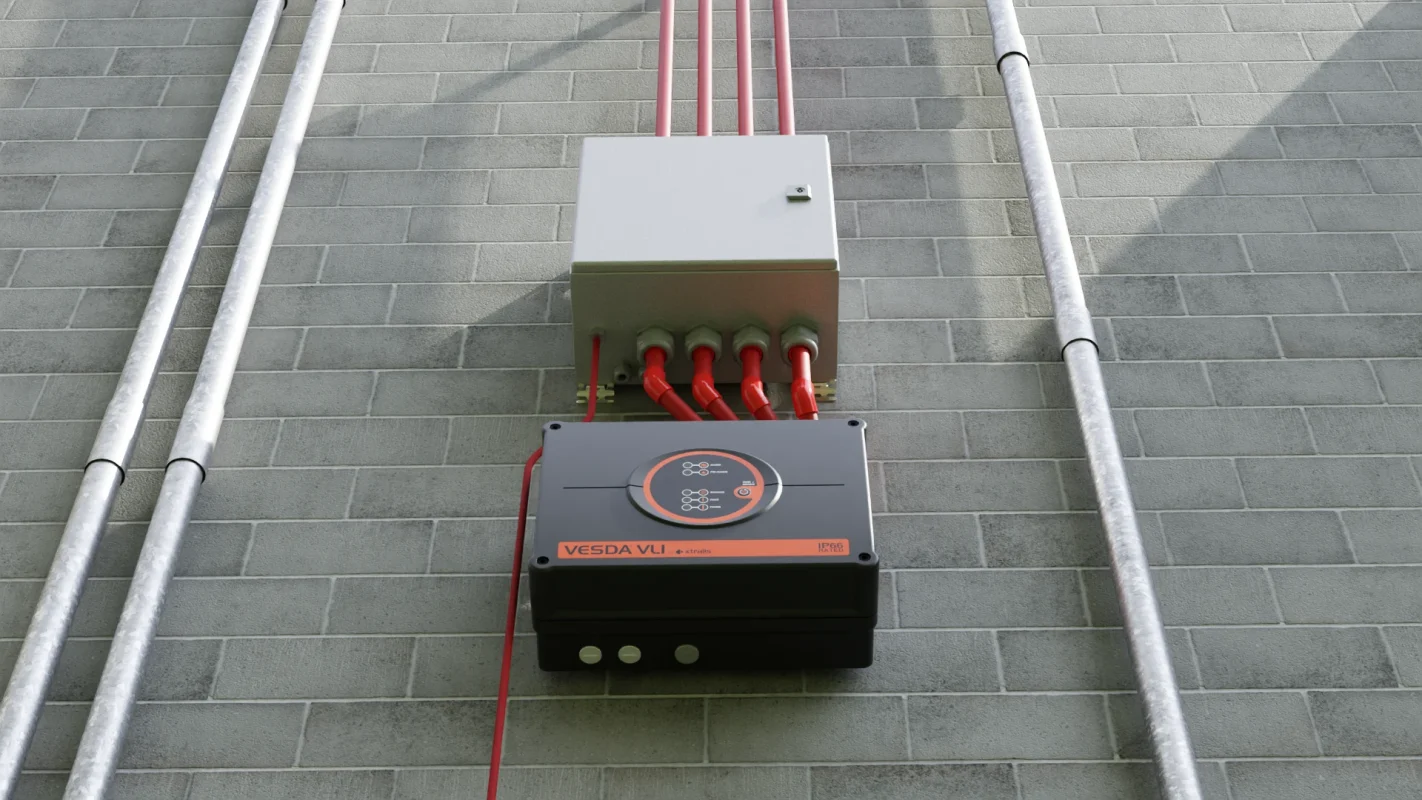

Aspirating smoke detection (ASD) is an advanced fire detection technology that presents an outstanding solution for protecting harsh environments from fire.

ASD works by using a network of sampling pipes to actively draw air into a sampling chamber in a central detection unit and offers several advantages over conventional point-type smoke detectors.

- Early detection

- ASD systems can detect smoke at its incipient stage, providing early warning of fire threats before they escalate.

- High sensitivity

- ASD systems are highly sensitive to smoke particles, even in environments with high levels of dust, debris, or other airborne contaminants.

- Adaptability

- ASD systems can be customised with different sensitivity levels and sampling configurations to suit the specific needs of different environments.

- Remote sampling

- ASD systems can monitor inaccessible or hazardous areas through their network of sampling pipes, allowing for comprehensive coverage of the protected space.

- Continuous monitoring

- ASD systems provide continuous monitoring of air samples, enabling real-time detection of smoke or fire events.

In environments with high levels of airborne particles, such as dust or dirt, regular cleaning or purging of the sampling pipes is essential to ensure reliable operation of the ASD system. In combination with an automatic purging system, which maintains the cleanliness and effectiveness of the system’s sampling pipes, harsh environments can be more effectively protected from fire.

Enhancing ASD with The Blazer

The Blazer automatic aspiration maintenance system effectively cleans the network of pipes above the detector in an ASD system. It uses pressurised air pulses to remove accumulated dirt, even stubborn contaminants, ensuring that fine dust from various processes is efficiently removed. The system’s programmable logic controller allows scheduled cleaning, which can be set daily, weekly, or between shifts, including weekends. During cleaning, the aspiration system operates continuously without interruption.

The Blazer system aims to ensure optimal performance, extending the lifespan of the aspiration system and enhancing operational reliability. It minimises the risk of detector alarms caused by blockages and reduces filter replacement frequency. The system requires a minimum pressure of 4 atmospheres and utilises high-quality valves and components to handle these pressure levels. Cleaning cycles start sequentially based on the number of connected pipes, ensuring thorough maintenance.

Key Features

- Reduces filter replacement

- Reduces the wear and tear of the ASD

- Stops the transport and lifting of vacuums and compressors

- Reduces call outs caused by flow faults

- Lowers the overall cost to maintain

How It Works

Why Choose Eurofyre?

- Complete System Supplier

- Eurofyre supplies all aspects of fire detection including aspirating smoke detection systems and its associated products and can provide expert advice and consultation.

- After-Sales Support

- Eurofyre offers both on-site and telephone support to assist you in ensuring that your ASD system is fully functional and operating at maximum efficiency. Our after-sales care and support are second to none.

For more information about Aspirating Smoke Detection and the products available, including VESDA systems, or to discuss any of the other products that Eurofyre has to offer, please feel free to get in touch either by phone on +44 (0) 1329 835 024, by email to [email protected] or via the online enquiry form situated on our contact page.

Don’t forget you can follow us on LinkedIn, X and Facebook or sign up to our newsletter (in the footer below) to receive all the latest information from Eurofyre.