Photovoltaic panels, or solar PV panels, convert sunlight into electricity and can be mounted in various locations to harness sunlight effectively.

When sunlight hits the surface of a solar panel, it excites electrons within the semiconductor material, generating an electric current. This current can then be harnessed and used to power electrical devices or be stored in batteries for later use.

Mounting solar panels on commercial or industrial roofs offers several advantages, including making use of unused space for renewable energy generation, reducing electricity bills, and demonstrating a commitment to sustainability. However, it’s essential to consider factors such as roof orientation, shading, structural integrity, and local regulations when planning and installing solar PV systems.

The most commonly recognised location for installation is on rooftops where panels have the best opportunity to capture the sun’s rays, but this isn’t always feasible due to structural issues. Other mounting options are available, including using integrating panels into the roofing materials themselves (a popular option on new builds), installing solar panels on purpose-built canopies over car parks and other outdoor areas, or even ground-mounted systems which utilise unused land.

What are the Risks?

While solar PV panel roof installations are generally safe, there are some fire risks associated with them, particularly if proper installation, maintenance, and safety measures are not followed. Some risks associated with solar PV panel roof installations include:

- Electrical Fires

- If components are improperly installed, damaged, or become degraded over time, they can pose a fire risk. Electrical faults, such as short circuits or overheating due to loose connections, can lead to electrical fires.

- Overheating

- Dust, debris, or vegetation accumulation on solar panels can create shading or hot spots, leading to potential overheating of the panels. This can result in fires, especially during periods of high sunlight intensity when panels are operating at maximum capacity.

- Combustible Roof Materials

- Some roofing materials used in commercial or industrial buildings, such as wood or certain types of insulation, can be combustible. If a fire occurs, the combustible materials could contribute to the spread and intensity of the fire.

- Poor Installation

- Poorly installed solar PV systems, including inadequate mounting, insufficient clearance between panels and roof surfaces, or incorrect wiring, can increase the risk of fire.

- Battery Storage Systems

- PV systems integrated with battery storage for energy storage may pose additional fire risks associated with the batteries themselves, including thermal runaway, electrolyte leakage, or battery management system failures.

What are the Challenges?

- Accessibility

- Solar PV roof installations are often located on large commercial or industrial buildings with expansive roof areas, making access challenging for the routine inspection and maintenance of fire detection equipment.

- The presence of solar panels, mounting structures, wiring, and other equipment on the roof can obstruct the line of sight and interfere with the operation of traditional fire detection devices, such as smoke detectors or heat sensors.

- Environmental Factors

- Fire detectors can suffer from reduced sensitivity due to environmental conditions, including temperature fluctuation, humidity, dust, and debris accumulation, which can affect performance and reliability.

- Integration with Building Systems

- Integrating fire detection systems with existing building systems, such as HVAC (heating, ventilation, and air conditioning) systems or building automation systems, can be complex, particularly in retrofit applications.

- Maintenance

- Routine maintenance and testing of fire detection equipment in solar PV roof installations can be logistically challenging, requiring specialist equipment and expertise to access rooftop locations safely.

Addressing these challenges requires careful planning, coordination, and implementation of appropriate fire detection strategies tailored to the specific characteristics of solar PV roof installations.

Linear heat detection (LHD) is one such solution for protecting rooftop solar PV installations; these systems are impervious to many environmental factors, can be installed in various configurations to suit irregular roof layouts, and can provide coverage of large areas for comprehensive fire monitoring.

FyreLine Digital

FyreLine Digital linear heat detection offers a cost-effective, easy-to-maintain solution for rooftop solar PV protection. Fyreline Digital can be integrated into both conventional and analogue addressable fire alarm systems and is easy to install, requiring minimal maintenance compared to other fire detection technologies.

FyreLine Digital is unaffected by weather conditions and environmental factors, is low-maintenance and easy to install. This means it can provide a cost-effective and reliable fire detection solution for this type of application with very little risk of false alarms.

Approvals

FyreLine Digital Linear Heat Detection is fully approved by the Underwriters Laboratories (UL). It is also CE marked to show it complies with all the applicable European directives including the CPR, EMC and the Low Voltage Directive (LVD).

FyreLine Digital Fixed Design Considerations

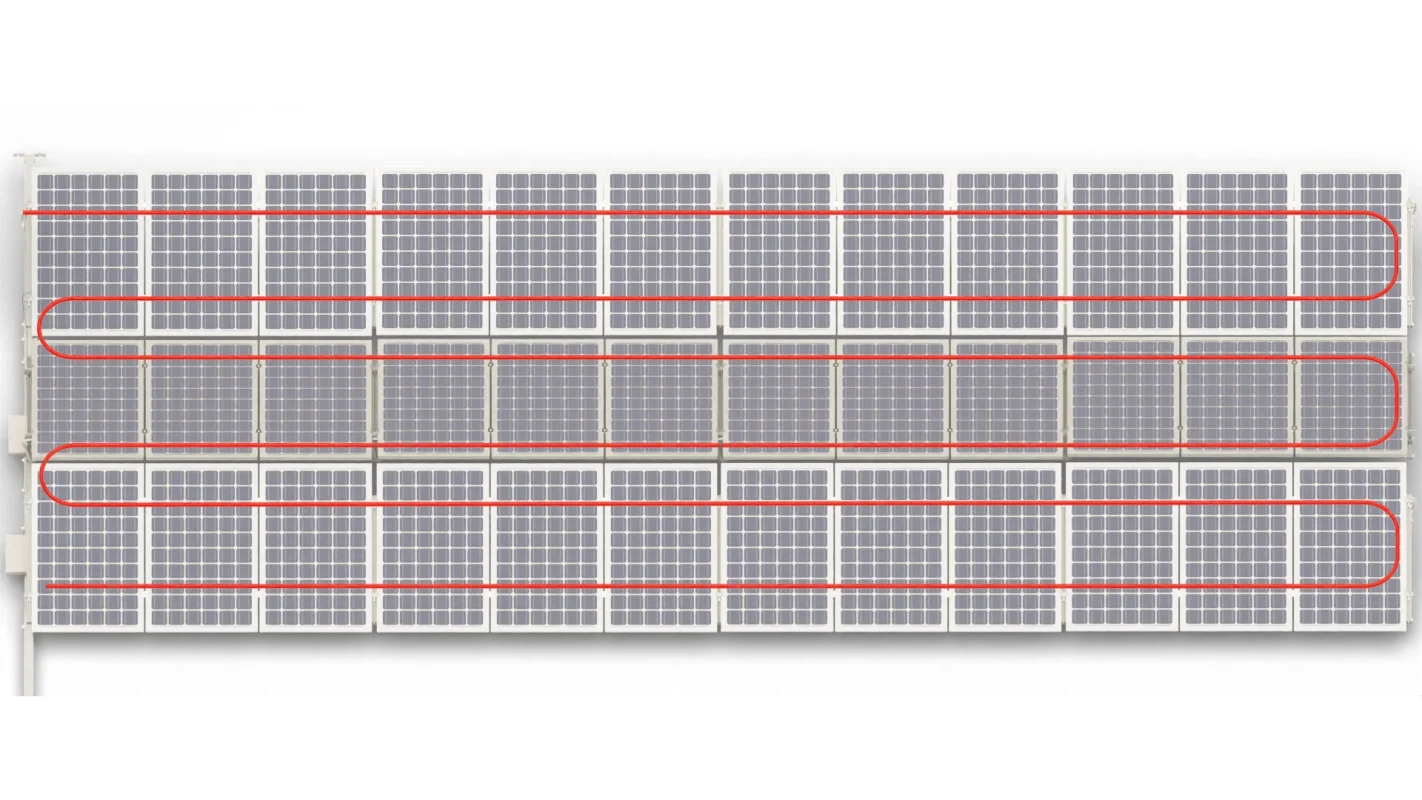

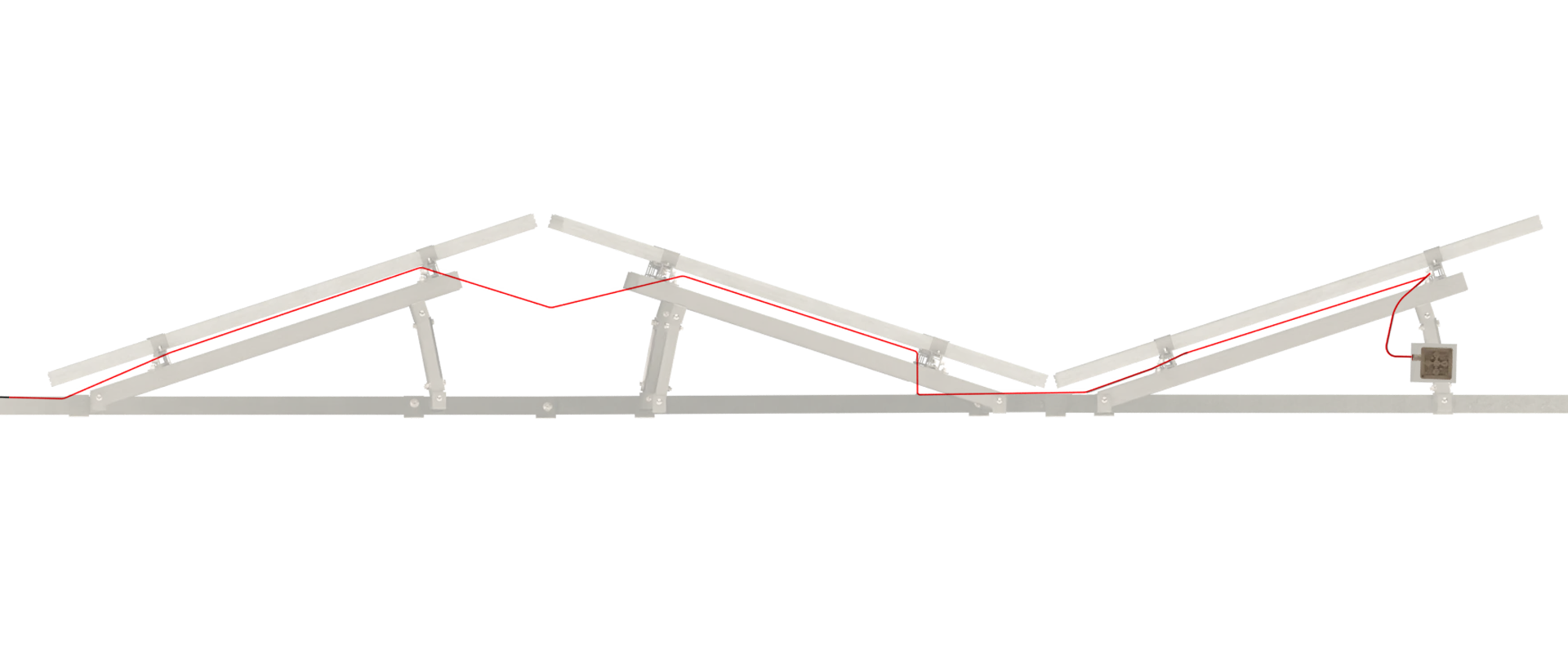

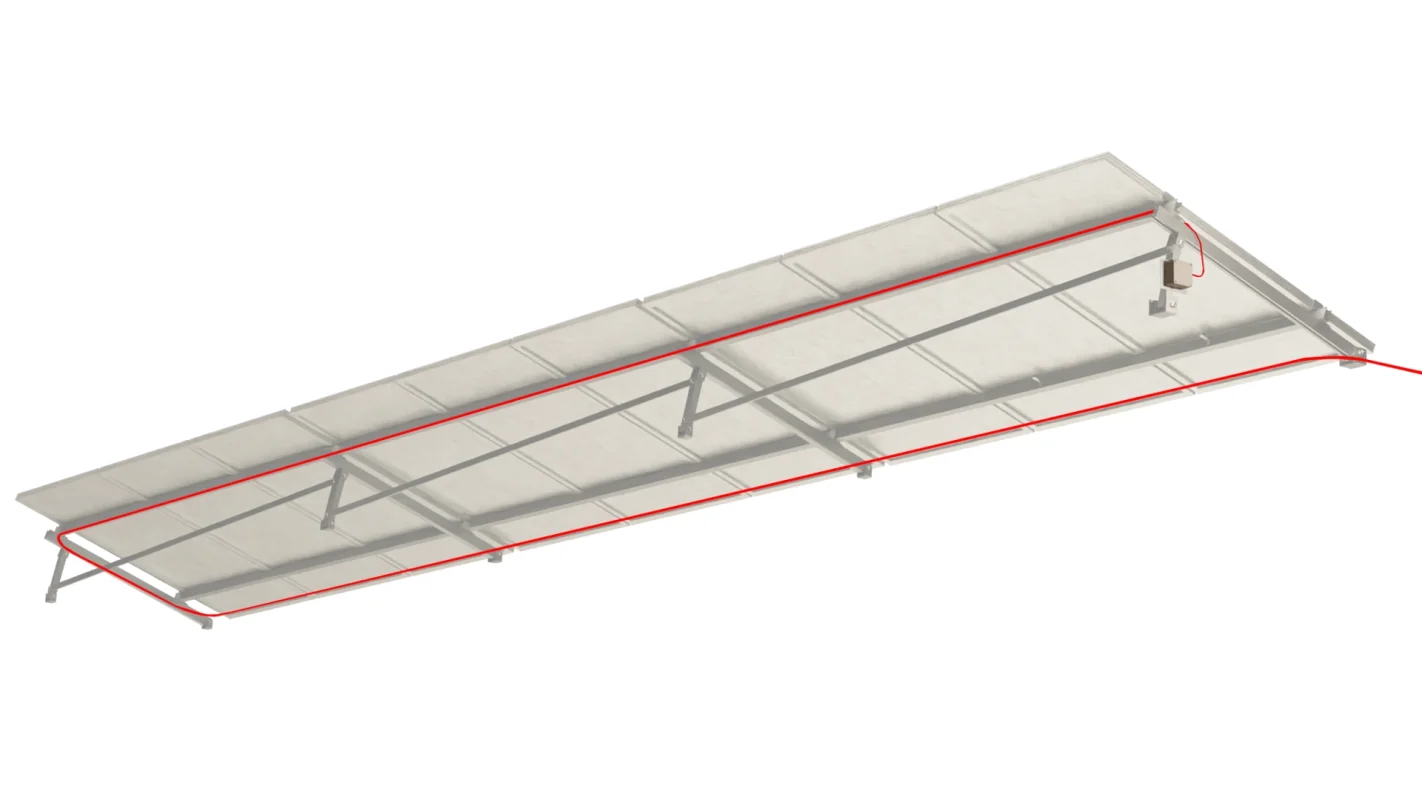

FyreLine digital heat sensing cable can be installed around each individual solar panel in the installation to provide accurate and reliable detection, while controllers can be installed in a secure, internal part of the building.

FyreLine Digital Controller Placement

FyreLine Controllers can be installed internally where they can be kept safe, secure and sheltered from the elements, this also helps to provide easy access for maintenance.

FyreLine Digital Linear Heat Detection Cable Placement

FyreLine Linear Heat Sensing Cable should be installed on the underside of the solar panels and along the highest longitudinal support bar of the metal framework that supports them.

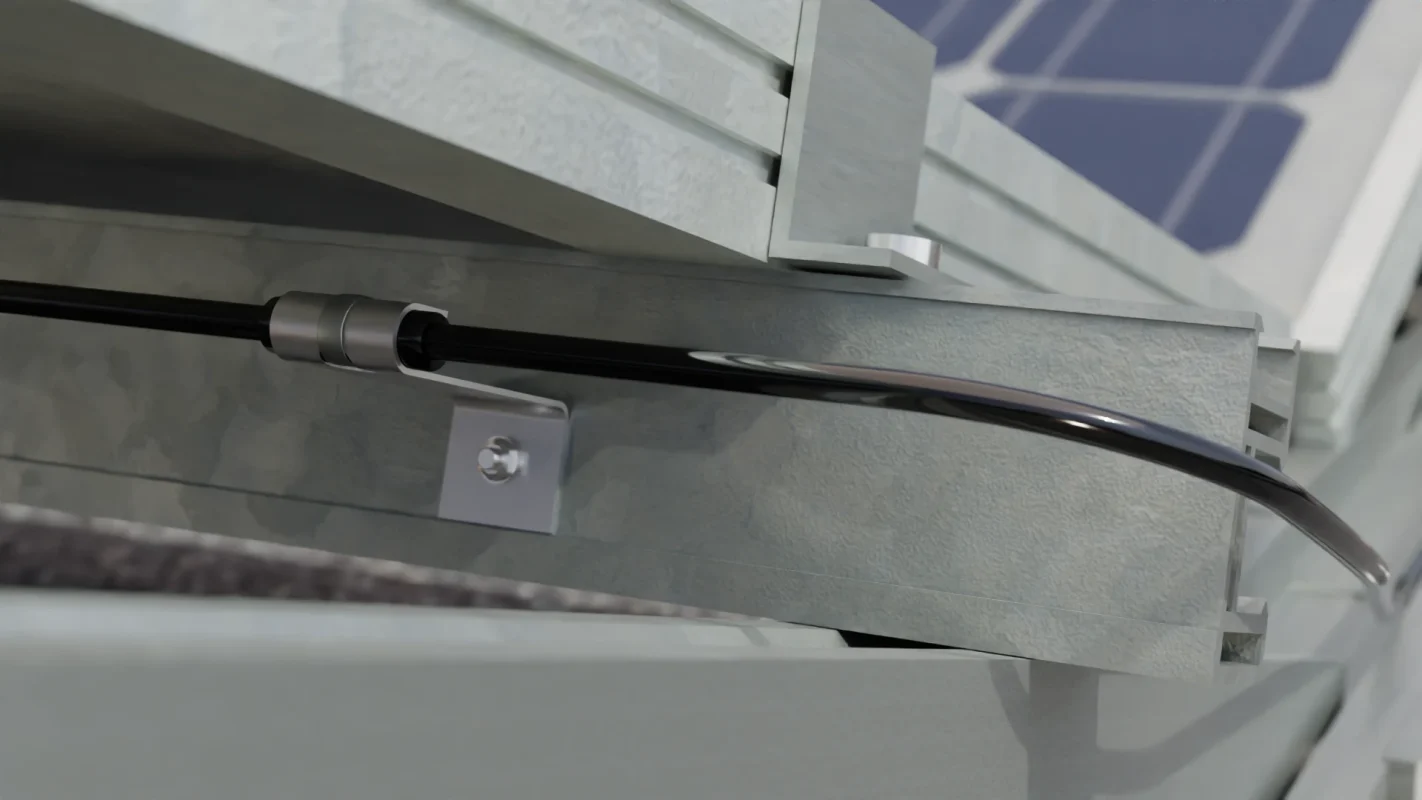

FyreLine Linear Heat Detection Mounting Clips

Steel mounting clips are available and should be used to mount the detector to the support bars and framework system.

FyreLine J-Clip

The J-Clip is suited for use on flat mounting surfaces and has provision for a cable tie to ensure the cable is securely fixed. It can be used to support the heat detection cable below or above the risk. Silicone sleeves are included to insulate and protect the cable from abrasion, excessive pressure or any heat transfer from the bracket to the cable.

FyreLine P-Clip

The P-Clip is available in aluminium and stainless steel and is suitable for use where mounting space is limited. When using the P-Clip, the cable passes through the clip. Silicone sleeves are included in each pack to insulate and protect the LHD cable from abrasion, excessive pressure and any heat transfer from a metal mounting bracket to the cable.

Independent & Interlock/Coincidence Detection

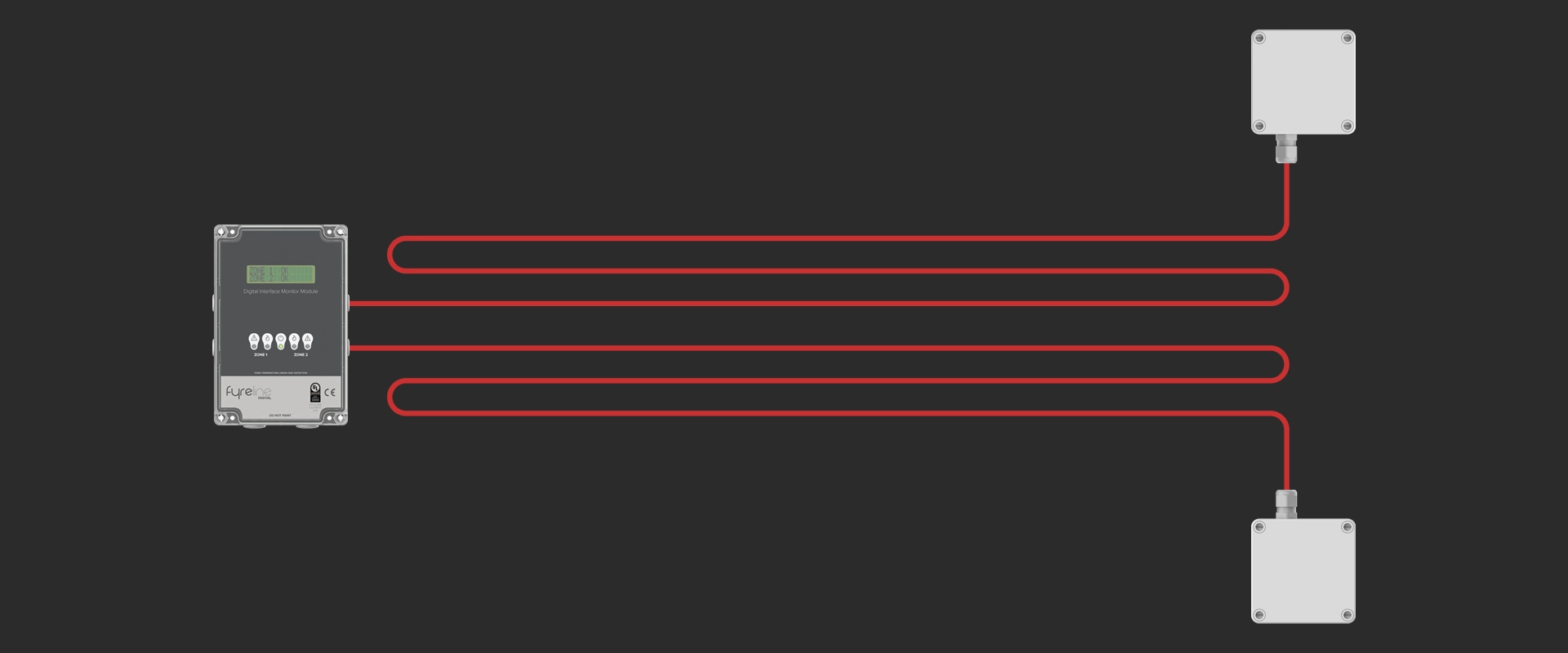

FyreLine Digital supports up to two zones and can be configured for operation in two different modes; interlock and independent.

Independent Mode

When configured for independent mode, each of the two zones operate independently. When a fault or overheat condition occurs in a zone, the corresponding fault or alarm output is triggered. In this mode, each zone can use either identical rated temperature LHD cables or different rated temperature LHD cables.

Interlock Mode

In Interlock mode, also known as coincidence detection, two Fixed LHD cables of the same temperature rating are used for both zones. The alarm output is then only activated when both LHD cables trigger an alarm due to an overheat condition. This ensures that an alarm is only triggered when an overheat event has occurred, preventing alarms that might occur if a mechanical or other issue has caused only one of the sensing cables to trigger an alarm.

External Functional Alarm & Fault Testing

The FyreLine EOL is used to terminate heat sensing cable and can accommodate up to two zones. It has built-in switches that are used to simulate fault or alarm conditions to allow the system to be fully tested in situ, all housed in a secure, weatherproof enclosure.

Why Choose Eurofyre?

- Complete System Supplier

- Eurofyre supplies all aspects of fire detection including linear heat detection and its associated products and can provide expert advice and consultation.

- Demonstration and Training

- We offer demonstrations and expert training on a range of systems, including FyreLine linear heat detection systems, in our very own sophisticated training facility.

- After-Sales Support

- Eurofyre offers both on-site and telephone support to assist you in ensuring that your system is fully functional and operating at maximum efficiency. Our after-sales care and support are second to none.

For more information about FyreLine Linear Heat Detection, or to discuss any of the other products that Eurofyre has to offer, please feel free to get in touch either by phone on +44 (0) 1329 835 024, by email to [email protected] or via the online enquiry form situated on our contact page.

Don’t forget you can follow us on LinkedIn, X and Facebook or sign up to our newsletter (in the footer below) to receive all the latest information from Eurofyre.