Key Features

- Cost effectively installs on existing ASD pipe network

- Centralised monitoring for real-time awareness

- Each ECO detector is pre-configured with one or two sensors

- Simple expansion to monitor multiple gases

- Integrates with PLCs/HVAC/BMS/FACP

Product Discontinued

This product has now been discontinued and has been replaced by the VESDA Sensepoint XCL Gas Detector. Please note: spare parts for ECO Gas Detectors are still available. Please contact Eurofyre for further information, servicing and training.

Overview

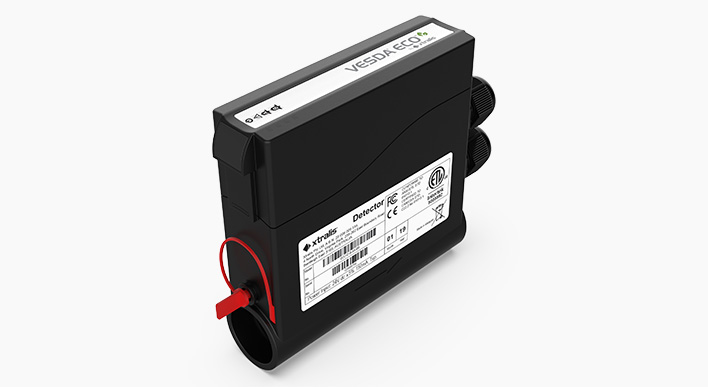

Xtralis the manufacturer of the market leading VESDA and VESDA-E aspirating smoke detection (ASD) technology has developed the industries first multi-hole aspirated gas detector.

When used with the ICAM, VESDA and VESDA-E range of ASD products; ECO provides the industries first combine aspirated smoke and gas detection system. ECO provides early warning of toxic, oxygen and flammable gas hazards to protect personnel and property whilst ensuring business continuity.

How it Works

ECO uses an existing or new aspirating pipe network to actively monitor for gas escapes and build-ups.

Each ECO gas detector can house up to two gas sensors, and additional detectors can be added easily to the ICAM pipe network to monitor more gases if required. Pre-calibrated sensor cartridges are easily replaced in the field and make converting to different gas sensors or replacing sensors a simple task.

The ECO detector is configured using Xtralis VSC configuration software and can be remotely monitored using Xtralis VSM4 monitoring software. Both VSC and VSM can be used to download data from the on-board memory card for data analysis and trending of historical data.

Integration with other building systems, including fire alarm control panels, PLCs, HVAC and building management systems, provides real-time situational awareness for intelligent emergency response.

ECO by Xtralis provides significant installation and routine maintenance cost savings over conventional multi-point gas detection solutions, by reducing the number of detectors required to cover an area and by providing easy access for routine maintenance.

Hazardous area certified variants of ECO are available (approval pending).

Installation

ECO is designed to press fit onto 25mm air-sampling pipe work. To fit ECO simply remove a 60mm section of pipe when using 25mm air sampling pipe work or 4” for ¾” BSP pipe. ECO provides total flexibility to install one or more detectors anywhere on the pipe network enabling monitoring of a specific point, zone or total area.

Additional Features

- Simple inline installation

- 4-wire RS485 Modbus network

- Configurable relays

- 4-20 mA analogue outputs

- On-board data logging

Each ECO detector can house up to two gas sensors, and additional detectors can be added easily to the pipe network to monitor more gases if required. The enhanced ECO can be configured to detect:

Applications

| Battery-charging rooms |

| Underground utility tunnels |

| Boiler rooms |

| Warehouses |

| Manufacturing facilities |

| Parking garages |

| Transportation centers |

Approvals

| EMC |

| FCC 47CFR Part15B class B |

| ICES 003 |

| EN 50270, CE |

| ETL listed to UL 61010-1 (pending) |

| ETL listed to CAN/CSA C22.2 (pending) |

| No.61010-1 (pending) |

| EN 61010-1 (pending) |

Downloads

Buy

Eurofyre is an authorised distributor of Honeywell and has been a major technical wholesaler of Xtralis products since 2007. We offer expert advice and supply all aspects of VESDA, FAAST and ICAM aspirating smoke detection systems including pipework calculations, demonstration/training and excellent after-sale support.

Contact us to receive competitive trade discounts or apply online for a credit account.