Electrical transformers play a critical role in power distribution. They step voltage up or down so electricity can travel long distances efficiently and be delivered safely to homes, businesses and industrial sites. Electrical transformers are found in substations, manufacturing facilities, renewable energy installations and data centres. Without transformers, modern electrical infrastructure would not function.

Transformers operate under heavy electrical load and generate heat during normal use. They contain flammable insulating materials and faults can produce high temperatures in a short period of time. A minor issue, such as a loose connection or insulation breakdown, can escalate into overheating, arcing or an internal fire.

Proper fire protection is essential. A transformer fire can lead to extended power outages, expensive equipment damage and major disruption to critical services. In industrial environments it can also pose risks to personnel. Early detection reduces downtime. It protects assets and keeps essential systems running. It also supports regulatory compliance and insurance requirements in many sectors.

Risks

Electrical transformers come with a variety of fire risks, some of which include:

- Electrical faults

- Short circuits, overloading or insulation failure can generate intense heat. Local hotspots can quickly ignite surrounding materials.

- Overheating

- Restricted airflow, poor maintenance or high ambient temperatures can lead to heat buildup. Persistent overheating weakens insulation and raises the chance of ignition.

- Mechanical failure

- Loose connections, damaged wiring or worn components can create friction or arcing. Both introduce sustained heat and increase fire risk.

- Flammable materials

- Many transformers contain oil or flammable insulation. If a fault occurs, these fuels can intensify a fire and cause rapid spread.

- Human error

- Improper installation, delayed maintenance or incorrect operation can leave systems vulnerable. Small oversights can escalate into serious incidents.

Challenges

Designing an effective fire detection solution for transformers presents several challenges:

- Harsh operating environments

- Transformers are often exposed to dust, vibration, moisture and extreme temperatures. Detection equipment must withstand these conditions while maintaining reliability.

- Fires often begin as small hotspots or slow cable failures. Traditional point detectors can struggle to identify these issues before they escalate.

- Limited access

- Transformers are frequently installed in confined spaces, remote substations or restricted plant areas. This can make detector placement and maintenance difficult.

- High airflow and ventilation

- Cooling systems can disperse smoke before it reaches a conventional detector. A solution must detect heat changes or faults directly at the source.

- Safety and continuity

- Shutting down essential power equipment can be costly and disruptive. A detection system must provide fast, accurate alerts to allow early intervention without unnecessary downtime.

FyreLine EN54 Fixed Linear Heat Detection

FyreLine EN54 Fixed is a linear heat detection system designed to monitor temperature continuously along its entire length. It uses a fixed-temperature sensing cable that can be installed directly on or around critical transformer components, cable trays or enclosures. When any part of the cable reaches its rated alarm temperature, the control equipment receives an immediate signal.

The system delivers uniform detection with no coverage gaps. It is tested and certified to EN54-28, giving assurance of performance and compliance. Because it detects heat at the source, it provides fast warning in areas where smoke may not accumulate or reach a conventional detector. The sensing cable is flexible and robust, which makes it easy to install in confined locations or around complex shapes.

Approvals

FyreLine EN54 Fixed is fully tested and approved to EN54-28, the European standard for non-resettable line-type heat detectors. This certification confirms consistent performance, reliability and suitability for life safety applications. It gives installers, consultants and end users confidence that the system meets recognised industry requirements and is acceptable for regulated environments.

FyreLine EN54 Fixed Design Considerations

Controller Placement

The controller should be installed as close as practical to the protected transformer zone. Short cable runs between the controller and the sensing cable improve response times and reduce the risk of signal loss. Positioning the controller outside the immediate hazard area also protects it from heat, moisture and vibration, which helps maintain reliability. It must remain easily accessible for routine inspection and should be mounted at a safe working height with clear labelling. Good placement ensures faster alarm activation, cleaner system wiring and a more dependable early warning of fire.

LHD Cable Placement

FyreLine EN54 Fixed linear heat detection cable contains heat-sensitive polymers that break down at a defined temperature, creating a short between the inner conductors and generating an alarm. It provides continuous detection across the full cable length with a precise, fixed trip point.

For optimal performance, the cable should be installed on, or immediately above, high-risk surfaces such as terminations, bushings and cable entries. Runs should follow the heat path and maintain even spacing to avoid blind spots. Secure fixing at regular intervals prevents movement from vibration or airflow. Close proximity to likely fault points delivers the earliest possible heat pickup and a faster alarm signal.

LHD Mounting Clips

P-Clips provide a secure and cushioned mounting point for FyreLine Resettable LHD cables. They are best placed at regular intervals along the cable route. Their flexible grip helps prevent cable damage while maintaining firm support.

J-Clips are used to securely fix FyreLine Resettable LHD cables in place. They should be installed at regular intervals along the cable route to maintain proper positioning and tension. Placement should avoid contact with sharp edges.

Messenger Wire

A messenger wire can be added to support the linear heat detection cable where there is no suitable mounting surface. It provides a secure catenary fixing point, allowing the cable to be suspended at a consistent height and distance from the transformer. This maintains accurate positioning, prevents sagging and ensures the cable remains in the optimal detection zone.

External Functional Alarm & Fault Testing

The End-of-Line (EOL) module must be fitted at the end of each detection cable circuit to complete supervision and ensure correct fault monitoring. It should be installed in a clean, dry location outside the immediate hazard area, ideally within an enclosure rated to match the environment. Keeping the EOL accessible allows for easy testing and maintenance. The module’s location should minimise exposure to heat or vibration while maintaining the shortest practical distance from the protected zone for accurate loop integrity monitoring.

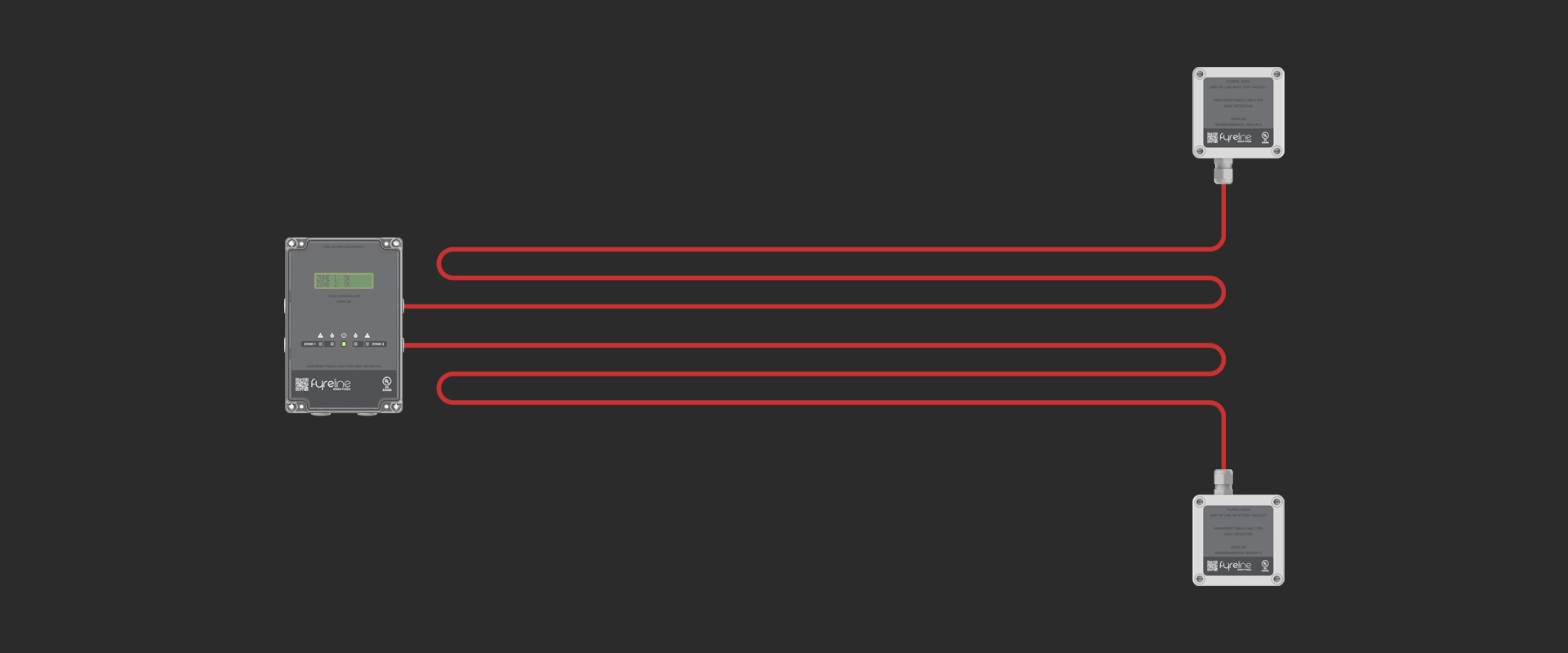

Typical Wiring Diagram

Independent Mode

In independent mode, each FyreLine EN54 Fixed controller operates as a standalone detection unit. It monitors its connected cable circuit independently and provides direct alarm and fault outputs without needing a central fire panel. This mode is useful for isolated or remote transformer installations where integration with a wider system is not required. It allows local visual and audible indication of alarm and fault status, and can activate relays for automatic shutdown or local alert devices. Independent mode ensures fast, reliable protection even where networked communication is unavailable.

Interlock Mode

In interlock mode, two FyreLine EN54 Fixed detection circuits must both reach alarm temperature before a fire signal is activated. This configuration reduces the risk of false alarms caused by transient heat or localised faults. It is particularly effective for transformer protection where redundancy and accuracy are critical. The two cables are typically installed in parallel paths or on separate sections of equipment, ensuring that a confirmed heat event is required before an alarm is triggered. Interlock mode provides added verification and system stability in demanding environments.

Why Choose Eurofyre?

- Complete System Supplier

- Eurofyre supplies all aspects of fire detection including linear heat detection and its associated products and can provide expert advice and consultation.

- Demonstration and Training

- We offer demonstrations and expert training on a range of systems, including FyreLine linear heat detection systems, in our very own sophisticated training facility.

- After-Sales Support

- Eurofyre offers both on-site and telephone support to assist you in ensuring that your system is fully functional and operating at maximum efficiency. Our after-sales care and support are second to none.

For more information about EN54 Fixed Linear Heat Detection, or to discuss any of the other products that Eurofyre has to offer, please feel free to get in touch either by phone on +44 (0) 1329 835 024, by email to sales@eurofyre.co.uk or via the online enquiry form situated on our contact page.

Don’t forget you can follow us on LinkedIn, Twitter and Facebook or sign up to our newsletter (in the footer below) to receive all the latest information from Eurofyre.